Report of Examination of Samples

U.S. DEPARTMENT OF LABOR

OCCUPATIONAL SAFETY & HEALTH ADMINISTRATION

Salt Lake Technical Center

8660 South Sandy Parkway

Sandy, UT 84070-6424

801-487-0073

FAX 801- 487-1190

November 9, 1998

Report of examination of samples received from XXXXXX1 pursuant to an investigation. A crate containing 10 samples was received on 27 July 1998 and opened on the same day. It has been held in my custody since then. Of the 10 samples sent to the Salt Lake Technical Center, two were examined. These were identified as XXXXXX #1 and XXXXX #8. XXXXX # 1 is a section of pipe with a nipple attached. This nipple was thinned at the end. XXXXX #8 was a valve into which the nipple attached before the failure.

The remainder of the samples were used as exemplars of typical assemblies.

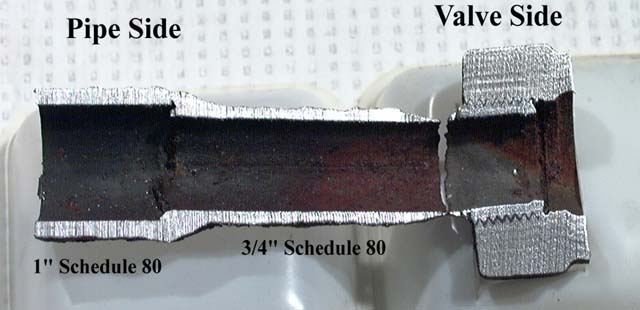

Sections were cut with a band saw from the pipe and from the valve to allow analysis of the pieces. Photo 1 shows the two pieces as they relate one to another based upon the cut sections. XXXXX #1 is represented in the photo as "pipe side" while the valve is represented by "valve side".

The pipe nipple was thinned through its entire thickness as it entered the valve body. The corrosion was grossly uniform around the circumference of the pipe. This is typical of galvanic corrosion. The material had essentially no strength at the time of failure. Measurements show that the large pipe has dimensions consistent with 1" schedule 80 steel pipe while the smaller nipple pipe had dimensions consistent with 3/4" schedule 80 steel pipe. The two sections were welded together to effect a reduction to 3/4" which was threaded to fit into the valve body.

The valve side piece was examined in the Scanning Electron Microscope (SEM) by X-ray Energy Dispersive Analysis (EDX) to determine the nominal composition of the metals. The valve was found to have silicon at about 1.5% which is consistent with cast iron. No other significant alloying elements were detected. The pipe analysis was limited to the 3/4" pipe. This was found to have no significant alloying elements. Based upon this measurement, it is determined that the pipe is steel and the valve body is cast iron.

Steel and cast iron differ in relative potential on the galvanic series as measured in seawater. It can therefore be expected that an electric couple will be established where these metals are in contact (such as where the pipe threads into the valve body.) If an appropriate electrolyte is present, galvanic corrosion can occur. To test if the particular metals of the valve and the pipe indeed had a galvanic potential, small pieces of the respective materials were placed in a saturated solution of table salt. The potential was measured with a digital multi-meter after allowing the apparatus to equilibrate for 2 hours. The result was consistent with the expectation that the steel was a less noble anodic metal than the cast iron. This should result in a depletion of material at the anode (pipe) relative to the cast iron (valve). This is what was observed.

The joint failed as a result of stress applied to a pipe thinned by galvanic corrosion which occurred due to dissimilar metals placed in contact in an environment which promoted the galvanic corrosion.

1. Names have been deleted to protect privacy.