Solutions for Electrical Contractors eTool

Installation and Repair » Connecting and Fastening

Connecting and fastening tasks include splicing wires, connecting wires to switches, outlets, control and service panels as well as connecting to motors and appliances. All of these tasks can expose employees to a number of hazards including forceful exertions, awkward postures, repetitive motions and contact stress.

Potential Hazards

-

Frequent bending to retrieve materials stored below knee height.

-

Connecting wire to fixtures may involve using screwdrivers and other small hand tools. This process requires repetitive bending of the wrists while exerting finger force and is especially hazardous when numerous fixtures are mounted within a short period of time.

-

Using small tools (Figure 1) may result in contact stress to the palms and fingers as well as exertion of significant finger force using awkward hand positions.

-

Application of the connectors may require the employee to use significant finger force with twisting.

-

Continuous stripping of wires requiring pulling force and pinch grips.

Possible Solutions

- Conduct pre-planning to ensure that:

- employees are provided with appropriate height of work surfaces, such as using a saw horse with plywood as a work table for materials, to reduce bending.

-

tasks are managed to limit the time employees perform similar tasks that affect the same muscle-tendon groups. For example, intersperse hand intensive tasks with lifting tasks.

-

Use stab-in switches and outlets. For residential work, use self-locking stab-ins. For larger jobs, use stab-ins with a side-screw fastener.

-

Use tool-less connectors, such as low-voltage spring action screwless terminals (Figure 2) where only a small amount of force is needed to insert wire, and no twisting is required. These connectors are easier and faster to use, thereby increasing productivity and reducing ergonomic risks.

-

When stripping wires use proper size or spring-loaded strippers that are in good condition (sharp teeth). This reduces the amount of pulling force required.

Potential Hazards

-

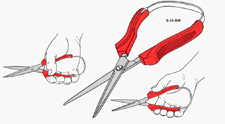

Using tools with short handles (Figure 3) may damage tendons and nerves by compressing unprotected areas of the palm and fingers.

-

Using tools that are too large for the hand may result in fatigue of the hand and forearm.

-

Using screwdrivers for highly repetitive tightening or loosening tasks may irritate the elbow tendons and their attachments, leading to inflammation and epicondylitis (tennis or golfer's elbow).

-

Wearing gloves that are too large or too thick may restrict movement of the hands, leading to muscle fatigue and overexertion. Conversely, gloves that are too tight may also restrict movement and blood flow.

Possible Solutions

-

Select tools with handles that are properly sized and shaped for the employee. The handle should be padded and made of slip-resistant material (rubber or plastic).

-

Use powered (Figure 4) or ratcheting tools whenever possible for repetitive tasks.

-

Ensure that powered tools have variable speed, torque limiters or stop bars to prevent over-tightening and wrenching of employee's hands.

-

Select tools that are light and fit well in the hand. Tools such as pliers or punches that extend into the palm should be rounded and padded (Figure 5).

-

Use spring-loaded pliers, snips (Figure 6), and crimpers for tasks that must be done frequently. Caution: Spring force should be just enough to open the tool. Excessive spring force will increase the grip force needed to use the tool.