Solutions for Electrical Contractors eTool

Ergonomic Solutions » Back

The following describes common ergonomic risk factors (such as reaching and tilting the head back) that may increase the chance of injury and pain to the shoulder, neck, and upper back. General solutions that may minimize the possibility of injury and pain are also presented.

Potential Hazards

-

When the torso is bent forward or to the side, the weight of the upper body must be supported as well as any other objects held in the hands. Employees who must work for prolonged periods of time in a bent-at-the-waist posture put significant strain on the back even if they are not lifting significant weight.

-

Twisting and bending pulls the back out of its normal alignment. This can pinch and alter the discs, making them more susceptible to bulging and rupture. This also forces the muscles of the back to work singularly instead of in tandem, making them more susceptible to overexertion and strain.

-

Finally, maintaining static postures for prolonged periods slows nutritional flow and removal of wastes to the muscles and tendons. This can create fatigue making them more susceptible to injury.

Possible Solutions

-

Keep the load directly in front of the body. Avoid reaching to the side or twisting when lifting.

-

Keep the load close to the body when lifting.

-

Use automation whenever possible to reduce repetition and duration of lifting tasks performed in awkward postures.

-

Reposition loads so most lifts can be performed at about waist height with the elbows in close to the body.

-

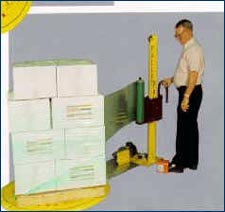

Use positioning devices, such as scissor lifts, lifter/tilters and palletizers, to raise and position loads so they can be lifted while close to the body with the back in a straight alignment.

-

Use devices with rotating platforms so loads can be easily positioned close to the body before lifting.

-

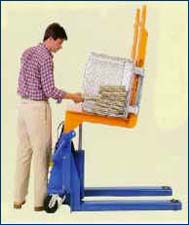

Use elevating and tilting bins, which elevates the load and keeps it close to the body.

Potential Hazards

Some loads are too heavy for most of the population to lift, even if all lifting conditions are ideal. Extensive studies have shown that even under ideal conditions, loads heavier than 50 pounds will increase the risk of injury. The following factors will further reduce the amount of weight that can be lifted safely.

-

Bending the torso forward moves the load away from the body and forces the back to support the weight of the upper body.

-

Reaching to access and lift a load also moves the load away from the body.

-

Frequent repetition of lifting motions leads to poor lifting techniques and muscle fatigue.

-

Twisting while lifting places the back in a less-stable posture and places the back in a less-stable posture.

-

Lifting for long periods of time leads to fatigue.

-

Previous back injury.

Possible Solutions

-

Evaluate lifting tasks to determine the maximum weight that can safely be lifted.

-

Do not manually lift heavy loads. For most people, loads heavier than 50 pounds should be considered heavy. Situations that involve awkward postures such as bending, reaching, or twisting or repetitive lifting will greatly reduce this weight.

-

Use lifting assist devices to lift loads that are determined to be excessive. These devices allow loads to be lifted by mechanical means rather than forcing employees to support the weight. Some examples of such devices include:

-

Powered barrel dumpers eliminate heavy lifting. Employees use a hand truck to load a heavily loaded barrel onto the device. It then automatically lifts the barrel and dumps the contents.

-

A counterweighted device, such as a vacuum hoist, allows employees to lift significant weight. Employees must exert only a few pounds of force to guide the load around the work space while mechanical means support most of the weight.

-

Conveyor systems or carts allow employees to transport items around the work station without repeated lifting and carrying.

-

Use of proper lifting techniques when performing manual lifts will minimize the risk to the back, but a heavy load still can cause injury even with perfect technique.

-

Maintain neutral spine alignment whenever possible. Usually, bending at the knees, not the waist, helps maintain proper spine alignment.

-

Keep the load close to the body. For large bulky loads, it may be better to bend at the waist instead of the knees because this will keep the load closer to the body. Do not reach to access a load.

-

Minimize bending of the body by keeping the load between shoulder and thigh height when lifting. Keep heavier loads off the floor.

-

Do not twist the body when lifting. Keep the load in front of the body

-

Lift heavier or bulky loads with a buddy.

-

Strengthen back and abdomen muscles that support your spine.

Potential Hazards:

-

Whole body vibration occurs while standing or seated in vibrating environments, such as trucks or heavy machinery.

-

Whole body vibration in a seated position has been found to increase the prevalence of reported low back pain. Operations such as tractor driving, forklift operating, truck driving, and driving earth moving machines have been found to result in increased back pain.

Possible Solutions

-

Provide vibration isolation for operator seats.

-

Provide padded seats with dampening material.

-

Remove debris and repair damage to flooring. Smoother driving surfaces will reduce vibration.

Potential Hazard

-

Pushing and pulling loads, such as carts, dumpers and gurneys, places stress on the back, especially when generating sufficient force to start and stop the devices. Factors such as the weight being moved, height of the handles, maintenance of equipment and flooring surfaces can greatly increase the risk of injury.

Possible Solutions

-

Limit the weight of loads to be moved manually. Generally, loads that require more than about 50 pounds of force to move require mechanical assists.

-

Use powered movers such as tugs to move heavy loads.

-

Keep carts, hampers, gurneys, etc., well maintained to minimize the amount of force exerted while using these items.

-

Use carts with large, low rolling resistance wheels. These can usually roll easily over mixed flooring as well as gaps between elevators and hallways.

-

Keep handles of devices to be pushed at waist to chest height.

-

Keep floors clean and well maintained.

-

Use a pendant handle when performing pulling tasks. This allows operators to lean away from the load so their body weight can assist in moving the load. This also reduces the chance of the cart running into their legs.

-

Push rather than pull whenever possible.