Shipyard Employment eTool

General Requirements >> Ladders

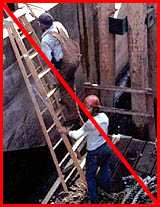

Ladders are used in shipbuilding and ship repair to allow workers to gain access to multiple levels, and in some cases to work from. Hazards associated with the use of ladders include falls from the ladder caused by structural failure, poor placement, and inappropriate work practices.

Fiberglass, aluminum, and ship's ladders, which are also used in the shipyard and their maintenance requirements are addressed under the general requirements. [29 CFR 1915.72(a)]

Note: There are specific requirements for construction of portable wooden ladders that are less than 30 feet and 30-60 feet. [29 CFR 1915.72(b) and (c)]

Additional requirements where ladders are used:

Note: Confined space entry is one of the leading hazards associated with barge cleaning. Review the Ship Repair: Confined or Enclosed Spaces and Other Dangerous Atmospheres chapter for information on how to protect workers from this hazard.

The safe construction and use of ladders can protect workers who are required to access multiple levels and when working from the ladder. Training workers on safe ladder use and how to assess the condition of the ladder before use is an important aspect of a safety and health program.

Potential Hazards

- Structural failure of the ladder or its components, causing the worker to fall.

- Inappropriate work practices (such as over-extending, climbing with equipment in hand, not facing ladder when climbing down), causing the worker to fall.

- Electrical shock or electrocution when using metal ladders.

- Inappropriate ladder placement (such as ladder angle), causing the worker to fall.

- Unsecured ladder causing the ladder and worker to fall.

Requirements and Example Solutions

- Defective ladders must not be used and must be removed immediately. [29 CFR 1915.72(a)(1)]

- When splicing ladders, special precautions are required. [29 CFR 1915.72(a)(2)]

- Portable ladders used for access must be secured and extend at least 36 inches above the upper landing. [29 CFR 1915.72(a)(3)]

- Manufactured portable metal or wood ladders must be in accordance with ANSI standards. [29 CFR 1915.72(a)(4) and (a)(6)]

- Portable metal ladders must not be used near electrical shock hazards (such as conductors, electric arc welding). [29 CFR 1915.72(a)(5)]

Additional Requirements

- Hand lines or tool bags must be used to keep workers hands free when using ladders. [29 CFR 1915.131(a)]

- Only use ladders for their designed purposes. [1910.23(b)(8)]

- Portable straight ladders must have a 4-to-1 ratio. Ladders must not be used in a horizontal position as platforms, runways, or scaffolds. [29 CFR 1910.23 (Figure D-1)]

- Employees visually restricted by blasting hoods, welding helmets, and burning goggles must work from scaffolds, not from ladders, except for the initial and final welding or burning operation. [29 CFR 1915.77(c)]

- Portable ladders must be used when the ship's ladders in the cargo holds are defective. [29 CFR 1915.76(a)(3)]

Additional requirements where ladders are used

- Scaffolds [29 CFR 1915.71]

- Access to Vessels [29 CFR 1915.74]

- Access to Drydocks and Marine Railways [29 CFR 1915.75]

- Access to Cargo Spaces and Confined Spaces [29 CFR 1915.76]

- Working Surfaces [29 CFR 1915.77]

- Lifesaving Equipment [29 CFR 1915.158(b)(5)]