Shipyard Employment eTool

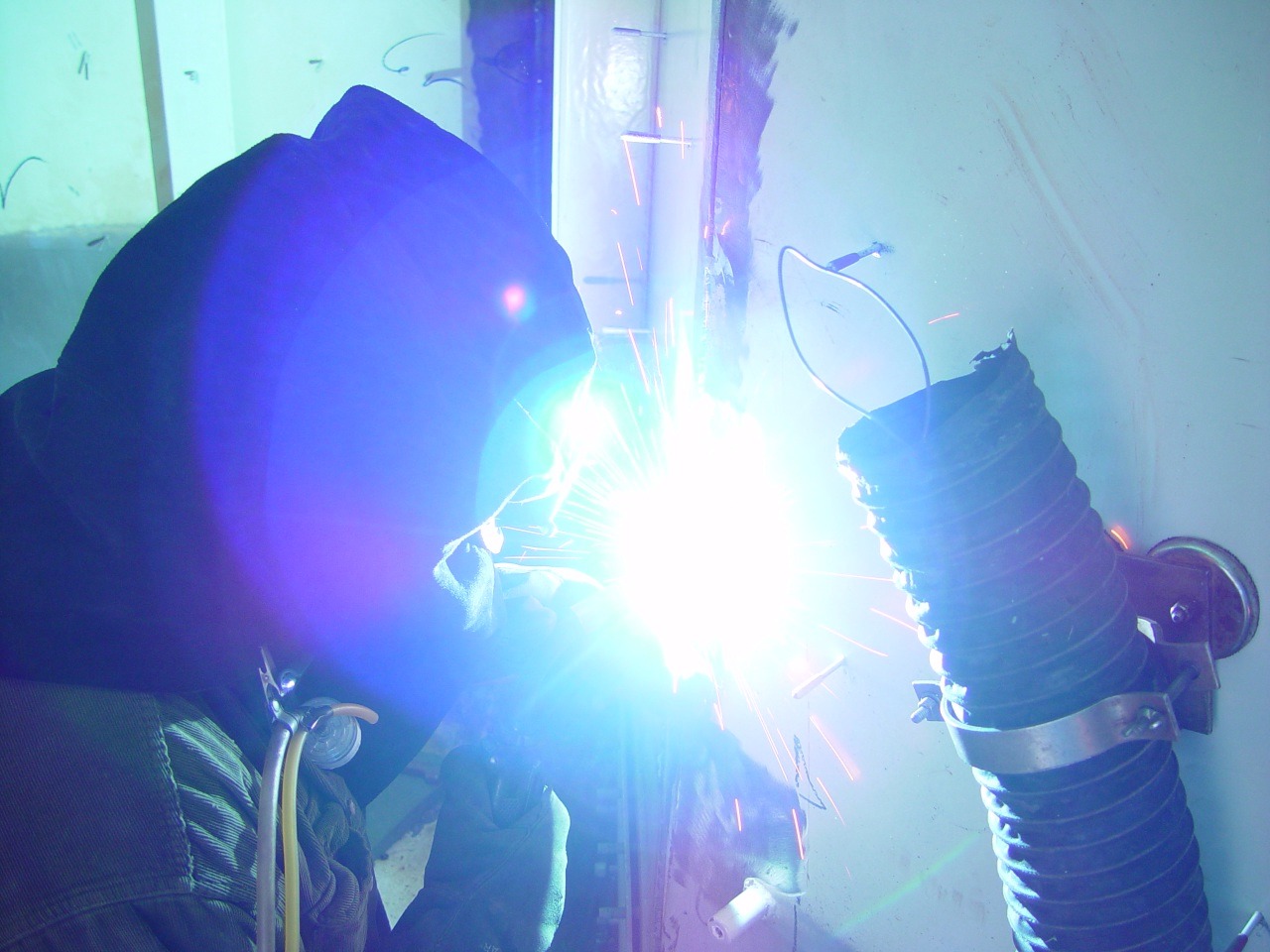

PPE Selection >> Hot Work

The OSHA Hierarchy of Controls

- Engineering Controls

- Administration Controls

- Personal Protective Equipment (PPE)

Hot work exposes workers to:

- Molten metal

- Toxic gases

- Fumes and vapors

- Harmful radiation

- Excessive noise

- Electrical shock

- Fire hazards.

Appropriate PPE must be selected to protect the worker from these hazards. [29 CFR 1915.152] Fire watches in the area will require similar PPE.

The personal protective equipment (PPE) specified for hot work will protect the worker from illness and injury during hot work operations. Hot work operations include:

- Gas welding and cutting (such as cutting, heating and brazing)

- Electric arc electric arc welding (for example stick, mig, and tig)

- Carbon arcing or plasma arc cutting

Each of these operations may present unique hazards. Use of the following PPE will provide protection:

Review the General Shipyard Worker PPE before proceeding with this section.

The PPE required when performing this operation must provide protection from:

- Hot metal,

- Metal fumes and welding gases,

- Noise from high oxygen-burners

- Infrared Radiation

PPE must be used if adequate engineering and administrative controls are not feasible to control the hazards. Each welding or cutting operation, depending on the materials welded on and the type of welding method, has specific safety and health hazards from which workers must be protected. A Hazard Assessment is required by 29 CFR 1915.152 to protect workers from the hazards associated with these operations.

The PPE required when performing this operation must provide protection from:

- Ultraviolet and infrared radiation

- Metal fumes and welding gases

- Electrical current

- Hot metal

- Noise

PE must be used if adequate engineering and administrative controls are not feasible to control the hazards. Each welding or cutting operation, depending on the materials welded on and the type of of welding method, has specific safety and health hazards from which workers must be protected. A Hazard Assessment is required by 29 CFR 1915.152 to protect workers from the hazards associated with these operations.

Note: Shielded arc welding produces high levels of toxic gases (such as Nitrous Oxide (NOx).

The PPE required when performing this operation must provide protection from:

- Noise

- Fumes and gases

- Ultraviolet and infrared radiation

- Electrical current

- Hot metal

PPE must be used if adequate engineering and administrative controls are not feasible to control the hazards. Each arc cutting operation, depending on the the materials used and the type of of application, has specific safety and health hazards from which workers must be protected. A Hazard Assessment is required by 29 CFR 1915.152 to protect workers from the hazards associated with these operations.

Hot work performed on the materials list below have special requirements as follows:

Confined and Enclosed Spaces

- Hot work performed on surfaces containing lead, cadmium, or mercury require an air-line respirator to be used if local exhaust ventilation is not provided or effective. [29 CFR 1915.51(d)(2)]

- Hot work performed on surfaces covered with toxic preservatives require an air-line respirator to be used if toxic coatings have not been stripped back at least four inches. [29 CFR 1915.53(d)(1)]

- Other workers exposed to the same atmosphere as the worker must be protected in the same manner. [29 CFR 1915.51(d)(4)]

- Hot work performed on beryllium requires local exhaust ventilation and air-line respirators. [29 CFR 1915.51(d)(2)(iv)]

- If the ventilation equipment blocks access to the space, air-line respirators as well as a stand-by employee must be available. [29 CFR 1915.51(c)(3)]

Open Air

- Hot work performed on surfaces containing lead, cadmium, or mercury require air purifying respirators to be used. [29 CFR 1915.51(d)(3)]

- Hot work performed on surfaces covered with toxic preservatives require a filter type respirator to be used. [29 CFR 1915.53(d)(2)]

- Other workers exposed to the same atmosphere as the worker shall be protected in the same manner. [29 CFR 1915.51(d)(4)]

- Hot work performed on beryllium requires air-line respirators to be used. [29 CFR 1915.51(d)(3)]

Note: There are additional PPE requirements for Health Related Hazards (such as, Lead [29 CFR 1910.1025], Arsenic [29 CFR 1910.1018], Asbestos [29 CFR 1915.1001], Cadmium [29 CFR 1910.1027]).

For more detailed information, review Respiratory Protection.

Hot work always produces significant eye and face hazards, including exposure to ultraviolet (UV) and infrared (IR) radiation.

Welding, Cutting and Burning Goggles

- Dark cutting or burning goggles must be used to protect the eyes from UV and IR light.

- A face shield used in conjunction with safety goggles or glasses may be used when necessary.

- The proper lens shade number for the operation must be used. [29 CFR 1915.153(a)(4)]

Welding Hood with Dark Glass

- Welding hoods with appropriately dark glass viewing ports must be used while carbon arcing to protect the worker's face, neck, and eyes from the arcs UV and IR light.

- The proper lens shade number for the operation must be used. [29 CFR 1915.153(a)(4)]

Hot work produces burn hazards in the form of heat, sparks, slag, and light radiation.

- Protection from sparks and slag must be provided. [29 CFR 1915.157]

- Note: Leather or other fire retardant garments provide such protection if they are free of flammable or combustible materials such as oil, grease, or solvents.

- To minimize burn hazards, remove all combustible items such as lighters or matches from pockets.

- To prevent slag and sparks from being caught in clothing, tape pockets and avoid wearing frayed clothing.

- Protection from carbon arcing flash (UV and IR light) is required. Cotton or wool long-sleeved and long-legged clothing can be used.

- Fire-retardant hoods should be used.

Hot work operations usually expose the workers feet to the hazard of falling or dropped objects, and sparks and slag.

- Spats with safety shoes may be used in lieu of high-top boots.

- High-top safety boots should be worn with the legs of the protective clothing over them to prevent slag from entering.

- Note: Boots should be fully laced or zipped. This gear protects the feet from falling or dropped objects.

Hot work operations expose the worker’s hands to burns and cuts.

- Long-cuffed leather gloves free of flammable or combustible materials must be used while carbon arcing.

- Leather gloves (or equivalent) free of flammable or combustible materials must be used while welding, cutting, or burning. [29 CFR 1915.157]