Shipyard Employment eTool

PPE Selection >> Cleaning and Other Cold Work

The OSHA Hierarchy of Controls

- Engineering Controls

- Administration Controls

- Personal Protective Equipment (PPE)

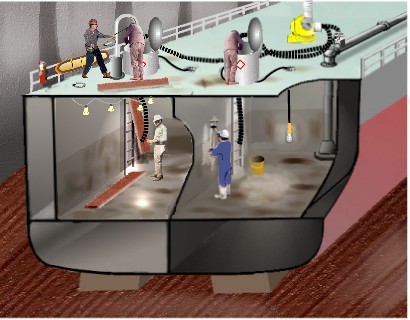

Cleaning and other cold work requires pre-planning and evaluation of the area/space for potential hazards before work is begun. Usually a Shipyard Competent Person (SCP), Certified Industrial Hygienist (CIH), or Certified Marine Chemist (CMC) will be needed to assist with the evaluation of hazards and selection of PPE. Additional hazards will exist if work is done in an enclosed or confined space (see confined space).

Cleaning operations present a significant risk for skin, eye, and respiratory exposure to toxic and corrosive chemicals in shipyard employment operations. In addition, cleaning operations often require the use of respiratory protection equipment. Employers must comply with 29 CFR 1915.154, which references 29 CFR 1910.134.

Typical cleaning and other cold work cleaning operations are as follows:

- Corrosive cleaners (e.g., acids and alkalis)

- Manual removal (e.g., Mucking)

- Water and steam cleaning

- Toxic cleaners (e.g., solvents/chemical/biological cleaners)

Each of these operations may present unique hazards. Therefore a qualified person must select PPE based on the specific cleaning operation. Use of the following appropriate combination of PPE will provide protection:

- Eye and face protection (e.g., face shield)

- Protective clothing

- Respirator protection (e.g., full or half face respirators)

- Foot protection

- Hand protection (e.g., gloves)

Review the General Shipyard Worker PPE before proceeding with this section.

PPE is required when using corrosive materials and must provide protection from their corrosive effects on the skin, eyes, and respiratory tract of the user. Strong acids and bases (such as hydrochloric acids, lye) are commonly used to remove petroleum residues. In addition to direct contact with these chemicals, reactions between the cleaner and the material being removed may produce toxic, flammable and combustible vapors or liquids. A Shipyard Certified Person (SCP), Certified Industrial Hygienist (CIH) or Certified Marine Chemist (CMC) can determine what PPE is necessary for the specific operation. It is important to have suitable quick emergency eye and body flushing facilities when corrosive cleaners are used. [ 29 CFR 1910.151(c)]

- Fixed or portable eye wash stations/safety showers should meet ANSI Z358.1-1998: Emergency Eye Wash and Shower Equipment.

PPE is required when removing residue by hand such as scraping, shoveling, or wiping. Primary hazards related to manual removal include skin (especially feet) and eye contact with the material or residue being removed.

A Shipyard Competent Person (SCP), Certified Industrial Hygienist (CIH) or Certified Marine Chemist (CMC) can determine what PPE is necessary for the specific operation.

PPE is required when using water or steam as a cleaner and must protect the worker from eye contact and skin burns. Water and steam can be at a high pressure, which can also cause trauma to the skin or eyes. The PPE should protect the worker from skin contact with the material being removed, which in many cases can be toxic or corrosive. A Shipyard Competent Person (SCP), Certified Industrial Hygienist (CIH) or Chemical Marine Chemist (CMC) can determine what PPE is necessary for the specific operation.

PPE is required when using toxic cleaners (such as Trichloroethane (TCE) and Methyl Ethyl Ketone (MEK)) and must provide protection from exposure to the liquid, vapors, or mists that present inhalation, skin contact, or absorption hazards. Care should be taken in the selection of the protective clothing fabric to ensure protection against the solvents. Reactions between the cleaner and the material being removed may produce additional toxic vapors or liquids. A Shipyard Competent Person (SCP), Certified Industrial Hygienist (CIH) or Certified Marine Chemist (CMC) can determine what PPE is necessary for the specific operation.

- Fixed or portable eye wash stations/safety showers should meet ANSI Z358.1-1998: Emergency Eye Wash and Shower Equipment.

Potential Hazard

Corrosive or toxic chemicals may splash or be sprayed onto worker's face and eyes.

Requirements and Example Solution

- Full-face respirators should be used when toxic chemicals that can be absorbed through the skin are used.

- Face shields and chemical goggles are necessary to protect the eyes and face from corrosive materials.

- Face shields alone do not protect the eyes. Safety glasses must be worn under the face shield for adequate protection.

For more detailed information, review Eye and Face Protection.

- Fixed or portable eye wash stations/safety showers should meet ANSI Z358.1-1998: Emergency Eye Wash and Shower Equipment.

Potential Hazards

- Chemical absorption or burns due to skin exposure to chemical cleaner or residues.

- Burns due to contact with steam or hot water.

- Hypothermia or frost bite from working in cold and/or wet conditions. (See Cleaning Operations: Work Environmental Temperature-Related Hazards.)

- Heat-related illnesses due to a combination of PPE use, heat-producing equipment, work activity, and environmental conditions. (See Cleaning Operations: Work Environmental Temperature-Related Hazards.)

Requirements and Example Solutions

- PPE should provide skin protection from:

- Corrosive and toxic chemicals that may be spilled, sprayed or splashed during their use.

- Water during pressure spraying.

- Steam burns and high-temperature water.

- Attached hoods should be used and when there is head or neck exposure.

- When respirators are used, hoods should be tightened over the respirator to prevent interference with the face seal and allow proper removal of gear.

- Heat or cold stress programs should be utilized.

Potential Hazards

- Worker inhalation exposure to toxic or corrosive chemicals.

- Exposure to oxygen-deficient atmospheres.

Requirements and Example Solutions

- Respirators must protect the lungs and upper respiratory track from mists, fumes and vapors that are associated with the cleaners and residues. [ 29 CFR 1915.154]

- Air supplied respirators are necessary to provide adequate respiratory protection in oxygen-deficient atmospheres. [ 29 CFR 1915.154]

- If a half face mask respirator is used, eye and face protection may also be required in the form of a face shield and goggles.

For more detailed information, review Respiratory Protection.

Potential Hazards

- Lacerations or amputations due to exposure to high-pressure water and steam.

- Slips and falls due to slippery surface.

- Foot related illnesses due to wading in water.

- Chemical absorption or burns due to skin exposure to chemical cleaner or residues.

- Burns due to contact with steam or hot water.

- Hypothermia or frost bite from working in cold and/or wet conditions. See Cleaning Operations: Work Environmental Temperature-Related Hazards.

- Crushing hazards from falling objects.

Requirements and Example Solutions

- Boots (e.g., chemical resistant, waterproof) should provide skin protection from:

- Corrosive and toxic chemicals that may be spilled, sprayed or splashed during their use.

- Trauma during high-pressure spraying.

- Steam burns and high-temperature water.

- Prolonged exposure to water and similar non-hazardous liquids.

- Boots should be worn with the legs of the protective clothing over them to prevent liquids from entering the boots.

- Slip-resistant soled boots should be worn when working on slippery surfaces.

For more detailed information, review Foot Protection.

Potential Hazards

- Chemical absorption or burns due to skin exposure to chemical cleaner or residues.

- Burns due to contact with steam or hot water.

- Frostbite from working in cold conditions. See Cleaning Operations: Work Environmental Temperature-Related Hazards.

Requirements and Example Solutions

- PPE should provide skin protection from:

- Corrosive and toxic chemicals that may be spilled, sprayed or splashed during their use.

- Water during pressure spraying.

- Trauma during high-pressure spraying.

- Steam burns and high-temperature water.

- Gloves should be sealed to the protective clothing to prevent liquids from entering the glove.

- For specific operations, inner gloves may be required.

For more detailed information, review Hand and Body Protection.