Shipyard Employment eTool

Shipbreaking >> Tools and Related Equipment

A variety of portable power and hand tools, such as grinders, drills, saws, and wrenches, are used in shipbreaking.

- Portable electric tools

- Hand tools

- Abrasive wheels

- Internal combustion engines (pumps and generators)

Improper use or lack of maintenance of tools and equipment can result in worker injuries. The following sections provide information about using tools safely:

Note: Confined space entry is one of the leading hazards associated with barge cleaning. Review the Shipbreaking: Confined or Enclosed Spaces and Other Dangerous Atmospheres and PPE: General Shipyard Worker chapters for information on how to protect workers from this hazard.

Potential Hazard

Damaged or defective electrical hand tools can cause burns, electric shock, and electrocution. Using tools without "deadman" switches may cause a worker to become entangled in the tool, potentially exposing the worker to cuts, amputations, and fractures.

Requirements and Example Solutions

- Portable electrical tools must be properly grounded, unless they are approved, double- insulated tools. [29 CFR 1915.132(a)]

- Grounding circuits must be checked. [29 CFR 1915.132(b)]

- Portable hand held tools must be equipped with a "deadman" switch. [29 CFR 1915.132(c)]

- Worn or frayed electric cables must not be used. [29 CFR 1915.132(d)]

- Insulating materials such as mats and gloves should be periodically tested or inspected.

- All electrical tools or equipment should undergo a visual inspection prior to use.

- All portable electric hand tools and temporary lighting systems should utilize Ground Fault Circuit Interrupters (GFCI).

- Electrical tools and equipment should correspond with the requirements of the job.

- Electrical equipment and tools should be equipped with proper circuit protection for the voltage and amperage used. See Figure 4.

- Only qualified electricians should attempt repair of electrical tools and equipment.

- A Ground Assurance Program should be in place for all electrical tools and equipment, including:

- Records of tools inspected and repaired.

- Records of electrical boxes inspected and repaired.

- Records of electrical extension cords inspected and repaired.

- Recall of records of the above.

- The requirements of the Ground Assurance Program should be performed on a regular basis.

Potential Hazards

Injuries that may result from the use of hand tools include:

- Cuts

- Punctures

- Fractures

- Eye injuries (See also Eye and Face Protection)

Requirements and Example Solutions

- Unsafe hand tools must not be used. [29 CFR 1915.133(a)]

- Wrenches must not be used when damage causes slippage to occur. [29 CFR 1915.133(b)]

- Impact tools, such as drift pins, wedges, and chisels, must be kept free of mushroomed heads. [29 CFR 1915.133(c)]

- Wooden handles of tools must be kept free of splinters or cracks and must be kept tight in the tool. [29 CFR 1915.133(d)]

Potential Hazards

- Cuts and amputations from grinders.

- Fractures from belts and pulleys and hand tools.

- Eye injuries from grinders.

- Punctures from work piece or debris when using hand tools.

- Hearing loss from noise.

- Inhalation of toxic materials or dust.

Requirements and Example Solutions

- Floor-stand and bench-mounted abrasive wheel grinders must be properly guarded and equipped with properly adjusted work rests (not to exceed 1/8 inch). [29 CFR 1915.134(a) and (b)] See Figure 6.

- Handheld grinders used for external use must be protected and have safety guards (see Figure 7.) with the following exceptions: [29 CFR 1915.134(c)]

- When the work location makes it impossible to use a guard, a wheel equipped with safety flanges must be used. [29 CFR 1915.134(c)(1) and (f)]

- Wheels less than 2 inches in diameter. [29 CFR 1915.134(c)(2)]

-

Handheld grinders used for internal grinding must be protected and have safety flanges except when: [29 CFR 1915.134(d) and (f)]

- Wheels are less than 2 inches in diameter. [29 CFR 1915.134(d)(1)]

- The wheel is entirely within the work, such as grinding inside of a pipe. [29 CFR 1915.134(d)(2)]

- Safety guards are required to: [29 CFR 1915.134(e) and 29 CFR 1910.243(c)(3), See Figure P-4.]

- Be properly aligned (see Figure 8).

- Be of sufficient strength.

- Have a maximum opening of 180 degrees (see Figure 8).

-

Abrasive wheels must be closely inspected and ring tested before mounting. [29 CFR 1915.134(g)]

- Grinding wheels must fit freely on the spindle and the spindle nut must not be over-tightened. [29 CFR 1915.134(h)]

- The power supply must be sufficient to maintain the rated spindle speed. Rated maximum speed of the abrasive wheel must not be exceeded. [29 CFR 1915.134(i)]

- Workers using abrasive wheels must be provided with eye and face protection. [29 CFR 1915.134(j)] See Figure 9. See also Eye and Face Protection.

- Abrasive wheels must be flat (properly dressed) and free of foreign matter such as copper, aluminum, and bronze residue. [29 CFR 1910.215(d)(3) and 29 CFR 1910.243(c)(5)(iii)]

Potential Hazard

Use of internal combustion engines in confined or enclosed spaces may expose workers to toxic gases such as carbon monoxide, nitrogen oxides, diesel exhaust.

Requirements and Example Solutions

- Exhaust from internal combustion engines, used in a fixed position below decks, must be vented into the open air and not recirculated back into the vessel. [29 CFR 1915.136(a)]

- All exhaust line joints and connections must be checked and free from leaks. [29 CFR 1915.136(b)]

- Carbon monoxide testing is required when internal combustion engines exhaust into the atmosphere below decks. Testing must be performed by the Shipyard Competent Person (SCP). Workers must be removed and the space must be ventilated when safe limits are exceeded. [29 CFR 1915.136(c)] See Figure 13.

Potential Hazards

Examples of tool-related injuries include:

- Fractures of the hand, arm or leg due to contact with belts, pulleys and, hand tools.

- Carbon monoxide poisoning from internal combustion engines.

- Embolisms from compressed air.

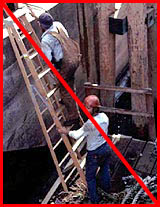

- Falls from climbing while holding tools. See Figure 12.

- Cuts, punctures, abrasions, and amputations from grinders, saws, hand tools, and powder-actuated fasteners. See also Hand and Body Protection.

- Eye Injuries from grinders, saws, and chisels. See also Eye and Face Protection.

- Hearing loss from noise. See also Hearing Protection.

- Inhalation of toxic materials and dust. See also Respiratory Protection.

Requirements and Example Solutions

- Workers' hands must both be free while climbing or descending. [29 CFR 1915.131(a)]

- When air tools of the reciprocating type such as chipping hammers are not in use, the dies and tools must be removed. [29 CFR 1915.131(b)]

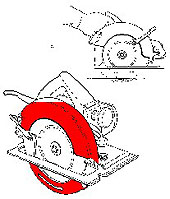

- Circular saws must be properly guarded. [29 CFR 1915.131(c)] See. Figure 12.

- The moving parts of machinery on dry dock ( pumps, winches, and compressors) must be guarded. [29 CFR 1915.131(d)]

- Extension hoses (whips) to pneumatic tools must be positively secured ( with pins, wires, or clamps). [29 CFR 1915.131(e)]

- Moving parts of drive mechanisms such as gearing and belting on large portable tools such as pumps, compressors, saws, and blowers must be adequately guarded. [29 CFR 1915.131(f)] See Figure 13.

- Compressed air manifolds and headers must be marked "air." [29 CFR 1915.131(g)]

-

Compressed air hoses must be examined before use. Visibly damaged and unsafe hoses must not be used. [29 CFR 1915.131(h)]

- Warning: Do not use oxygen for cleaning (blow-off), operation of air tools, or ventilation [29 CFR 1915.51(b)(1)(vi)].

- Ensure that the air supply is shut-off when changing pneumatic-powered tools.