|

Table 1. Types of Machine Guards

|

| Type |

Safeguarding Action |

Advantages |

Limitations |

Examples |

| Fixed |

Provides a barrier and is a permanent part of machine. |

- Can be constructed to suit many specific applications.

- Can provide Maximum protection.

- Usually requires little maintenance.

- Suitable to high production, repetitive operations.

|

- May interfere with visibility.

- Machine adjustment and repair often require removal of guard.

- Other means of protecting maintenance personnel often required (i.e., lockout).

|

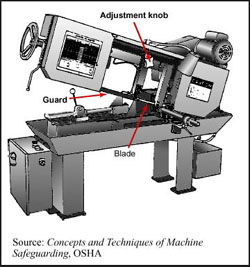

Use on:

- In-running rolls.

- Belts and Pulleys

(Fig. 4).

- Power transmission apparatus.

- Cutting Heads of Planers and other automatic-feed equipment (Fig. 5).

|

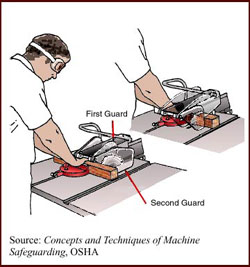

| Adjustable |

Provides a barrier that may be adjusted to facilitate a variety of production operations. |

- Can be constructed to suit many specific applications.

- Can be adjusted to admit varying sizes of stock.

|

- Hands may enter danger area. Protection may not be complete at all times.

- May require frequent maintenance or adjustment.

- Operator may make guard ineffective.

- May interfere with visibility.

|

Used on woodworking machinery, such as:

|

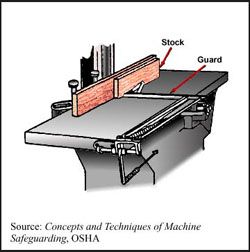

| Self-adjusting |

Provides a barrier that moves according to the size of the stock entering the point of operation. Guard is in place when machine is at rest. Guard pushes away when worker moves stock into point of operation. |

- Off-the-shelf guards are often commercially available.

- Do not require manual adjustments.

|

- Does not provide maximum protection.

- May interfere with visibility.

- May require frequent maintenance and adjustment.

|

Used on woodworking machinery, such as:

- Table saws (Fig. 8).

- Radial saws.

- Band saws.

- Jointers (Fig. 9)

|

| Source: Adapted from Concepts and Techniques of Machine Safeguarding, U.S. Department of Labor, OSHA. |