[Federal Register: December 29, 2005 (Volume 70, Number 249)][Rules and Regulations]

[Page 76979-77025]

From the Federal Register Online via GPO Access [wais.access.gpo.gov]

[DOCID:fr29de05-4]

=======================================================================

-----------------------------------------------------------------------

DEPARTMENT OF LABOR

Occupational Safety and Health Administration

29 CFR Parts 1926 and 1928

[Docket No. S-270-A]

RIN 1218-AC15

Roll-Over Protective Structures

AGENCY: Occupational Safety and Health Administration (OSHA), DOL.

ACTION: Direct final rule.

-----------------------------------------------------------------------

SUMMARY: In 1996, OSHA published a technical amendment revising the

construction and agriculture standards that regulate testing of roll-

over protective structures (``ROPS'') used to protect employees who

operate wheel-type tractors. This revision removed the original ROPS

standards and replaced them with references to national consensus

standards for ROPS-testing requirements. The Agency believed that the

national consensus standards essentially duplicated the ROPS standards

they replaced, and that any differences between them were not substantive.

Subsequently, OSHA identified several substantive differences between the

national consensus standards and the original ROPS standards. Therefore,

the Agency is reinstating the original ROPS standards by issuing this

direct final rule. The reinstated ROPS standards for both construction

and agriculture also contain a number of minor revisions that OSHA

believes are not substantive and will improve comprehension of, and

compliance with, the standards.

DATES: This direct final rule will become effective on February 27,

2006 unless significant adverse comment is received by January 30,

2006. If OSHA receives significant adverse comment, it will publish a

timely withdrawal of this rule. Submit comments to this direct final

rule by the following dates:

Hard copy: Submit (i.e., postmarked or sent) comments by regular

mail, express delivery, hand delivery, and courier service by January

30, 2006.

Electronic transmission and facsimile: Submit comments by January

30, 2006.

The incorporation by reference of specific publications listed in

this direct final rule is approved by the Director of the Federal

Register as of February 27, 2006.

ADDRESSES: Submit written comments to this direct final rule--

identified by docket number S-270-A or RIN number 1218-AC15--by any of

the following methods:

Federal eRulemaking Portal: http://www.regulations.gov.

Follow the instructions for submitting comments.

OSHA's Web site: http://dockets.osha.gov/. Follow the

instructions for submitting comments.

Facsimile: When written comments are 10 pages or fewer,

fax them to the OSHA Docket Office at (202) 693-1648.

Regular mail, express delivery, hand delivery, and courier

service: Submit three copies to the OSHA Docket Office, Docket No. S-

270-A, U.S. Department of Labor, 200 Constitution Avenue, NW., Room N-

2625, Washington, DC 20210; telephone: (202) 693-2350. (OSHA's TTY

number is (877) 889-5627.) Please note that security-related problems

may result in significant delays in receiving comments and other

written materials by regular mail. Telephone the OSHA Docket Office at

(202) 693-2350 for information regarding security procedures concerning

delivery of materials by express delivery, hand delivery, and messenger

service. The hours of operation for the Docket Office are 8:15 a.m. to

4:45 p.m., EST.

Additional materials: When a commenter would like to submit

additional materials (e.g., studies, journal articles) to supplement

comments that were submitted electronically or by facsimile, these

materials must be sent, in triplicate hard copy, to the OSHA Docket

Office, Technical Data Center, Room N-2625, OSHA, U.S. Department of

Labor, 200 Constitution Ave., NW., Washington, DC 20210. These

materials must clearly identify the sender's name, date, subject, and

docket number (S-270-A) or RIN number (1218-AC15) to enable the Agency

to attach them to the appropriate comments.

Personal information: OSHA will make available to the public,

without revision, all comments and other materials submitted to the

docket, including any personal information. Therefore, the Agency

cautions commenters about submitting statements they do not want made

available to the public, or submitting comments that contain personal

information (either about themselves or others) such as social security

numbers, birth dates, and medical data.

FOR FURTHER INFORMATION CONTACT: For general information and press

inquiries, contact Mr. Kevin Ropp, Director, Office of Communications,

OSHA, U.S. Department of Labor, Room N-3637, 200 Constitution Avenue,

NW., Washington, DC 20210; telephone: (202) 693-1999; fax: (202) 693-

1634. For technical inquiries, contact Mr. Mark Hagemann, Acting

Director, Office of Safety Systems, OSHA, U.S. Department of Labor,

Room N-3609, 200 Constitution Avenue, NW., Washington, DC 20210;

telephone: (202) 693-2255; fax: (202) 693-1663. For detailed

instructions on submitting comments and for additional information on

the rulemaking process, see the ``Public Participation'' heading under

the section below titled Supplementary Information.

SUPPLEMENTARY INFORMATION:

Table of Contents

I. Direct Final Rulemaking

II. Summary and Explanation of the Rulemaking

A. Basis for the Rulemaking

B. Substantive Differences Between the Standards

C. Minor Revisions to the Original OSHA ROPS Standards

III. Procedural Determinations

A. Legal Considerations

B. Economic Analysis and Regulatory Flexibility Certification

C. Paperwork Reduction Act

D. Federalism

E. State-Plan States

F. Unfunded Mandates Reform Act

G. Public Participation

List of Subjects

Authority and Signature

IV. Amended Standards

I. Direct Final Rulemaking

The Agency uses direct final rulemaking when it expects that a rule

will not be controversial. Examples of such rules include minor

substantive revisions to regulations, incorporation by reference of the

latest edition of a technical or industry consensus standard, and

direct incorporations of mandates from new legislation. In direct final

rulemaking, OSHA publishes a final rule in the Federal Register with a

statement that, unless it receives a significant adverse comment by a

specified date, the rule will become effective on a designated date

thereafter.

OSHA believes that the subject of this rulemaking is suitable for a

direct final rule. The Agency bases this decision on substantive

differences found between the original OSHA standards on roll-over

protective structures (``ROPS'') for the construction and agriculture

industries and the national consensus standards issued by the Agency

under a 1996 technical amendment to replace the original standards. By

replacing the original ROPs testing provisions through a technical

amendment, OSHA denied the regulated community an opportunity for

notice-and-comment on these substantive differences as required under

the Administrative Procedures Act (5 U.S.C. 553(b)) and the

Occupational Safety and Health Act of 1970 (29 U.S.C. 655(b)(2) and

(b)(3)). Therefore, the Agency has concluded that it has a legal

obligation to the regulated community to reinstate the original OSHA

standards through this direct final rule. (See section II.A below

(``Basis for the Rulemaking'') for a detailed discussion of the

Agency's legal analysis of this issue.)

Having concluded that this reinstatement action constitutes a

binding legal obligation, the Agency will consider as significant

adverse comments only those comments that address: (1) The lawfulness

of the procedures used to promulgate the 1996 technical amendment as

these procedures relate to the ROPs testing provisions; and (2) whether

the minor revisions made to the original ROPS standards in this direct

final rule (see a description of these revisions under section II.C of

this preamble) are reasonable or appropriate.

The Agency often publishes an identical proposed rule

simultaneously with a direct final rule. In this instance, however, OSHA

is not publishing a companion proposed rule. Should OSHA receive any

significant adverse comments to this direct final rule, it will

withdraw the rule and determine, based on the comments submitted to the

record, whether to issue a proposed rule in the future. Accordingly, if

OSHA receives timely significant adverse comments on the two issues

described in the previous paragraph, it will publish notice of the

significant adverse comments in the Federal Register and withdraw this

direct final rule no later than February 27, 2006.

II. Summary and Explanation of the Rulemaking

A. Basis for the Rulemaking

On March 7, 1996, OSHA published a technical amendment in the

Federal Register that revised a number of its standards. Section II.G

of the amendment revised the construction and agriculture standards

that regulate testing of roll-over protective structures (``ROPS'');

employers use these structures to protect employees who operate wheel-

type tractors. (See 61 FR 9228.) ROPS testing determines the capacity

of ROPS components to absorb energy (i.e., withstand fracturing) during

loadings administered under field and/or laboratory conditions, and

under different temperature conditions. The revision removed the

original, detailed ROPS-testing standards and referred instead to

national consensus standards for substantive ROPS-testing requirements.

The 1996 technical amendment was part of an OSHA initiative to

``undertake a line-by-line review of * * * regulations to determine

where they could be simplified or clarified'' (61 FR 9228).

The Administrative Procedures Act (APA) (5 U.S.C. 553(b)), the

Occupational Safety and Health Act of 1970 (OSH Act) (29 U.S.C.

655(b)(2) and (b)(3)), and OSHA's procedural regulations (29 CFR

1911.5) require that OSHA provide notice and an opportunity for comment

during substantive rulemaking. However, in the preamble to the 1996

technical amendment, the Agency noted that the technical amendment did

not revise the original ROPS standards in any material fashion, and

that ``[t]he substantive requirements are unchanged'' between the

original ROPS standards and the consensus standards that replaced them

(61 FR 9229). For this reason, OSHA determined that the technical

amendment did not require notice and an opportunity for comment because

it satisfied the ``unnecessary'' exemption specified by the APA (5

U.S.C. 553(b).\1\ Relying on the ``unnecessary'' exemption to notice

and comment, the Agency stated:

---------------------------------------------------------------------------

\1\ The three exemptions Specified by this provision of the APA

are: Impracticable, unnecessary and contrary to the public interest.

OSHA has determined that this rulemaking is not subject to the

procedures for public notice-and-comment rulemaking specified under

section 4 of the Administrative Procedure Act (5 U.S.C. 553) or sec.

6(b) of the Occupational Safety and Health Act of 1970 (29 U.S.C.

655(b)) because this rulemaking does not affect the substantive

requirements or coverage of the standards involved. This rulemaking

does not modify or revoke existing rights and obligations, and new

rights and obligations have not been established. Under this

rulemaking, the Agency is merely correcting or clarifying existing

regulatory requirements. OSHA therefore finds that public notice-

and-comment procedures are unnecessary within the meaning of 5

---------------------------------------------------------------------------

U.S.C. 553(b)(3)(B) and 29 CFR 1911.5. (61 FR 9229.)

Several years after issuing the 1996 technical amendment, the

Agency was informed that several of the original OSHA ROPS provisions

differed substantively from the national consensus standards for the

construction and agriculture industries (Ex. 4-7). In response to this

information, the Agency conducted a thorough evaluation of its original

ROPS standards and the ROPS testing requirements contained in the

national consensus standards referenced in its current construction and

agriculture ROPS standards. OSHA has included in the docket for this

rulemaking four side-by-side comparisons of the differences found

between the original OSHA standards and the referenced national

consensus standards (Exs. 4-1 to 4-4).

Based on the findings of this evaluation, which are described in

detail in the following section, the Agency has concluded that

differences do exist between its original construction and agriculture

ROPS standards and the ROPS standards implemented under the 1996

technical amendment, that these differences have a substantial impact

on the regulated community, and that OSHA incorrectly applied the APA's

``unnecessary'' exemption to the ROPs testing procedures. This

conclusion is consistent with existing case law. For example, in

Utility Solid Waste Activities Group v. Environmental Protection

Agency, 236 F.3d 749 (D.C. Cir. 2001), the court found that an EPA

technical amendment had a significant impact on the regulated community

and, most importantly, that it did not meet any of the three exemptions

to notice-and-comment rulemaking specified by the APA i.e., 5 U.S.C.

553(b)(B) (Id. at 754)). In vacating the technical amendment, the court

stated, ``The amendment * * * constituted agency action `without

observance of [the] procedure required by law' and, as such, it is

`unlawful and set aside.' 5 U.S.C. 706(2)(D).''

The substantive differences found between the standards and the

legal analysis described in the preceding paragraphs support the

Agency's conclusion that reinstating the original OSHA standards

through this direct final rule is necessary and appropriate.

Specifically, the Agency is revoking the references to the national

consensus standards for ROPS testing located in paragraphs 29 CFR

1926.1002(a)(i), 1926.1003(a)(i), and 1928.51(b)(1) and reinstating in

the construction and agriculture standards the original OSHA ROPS

testing provisions. For both the reinstated construction and

agriculture ROPS standards, the Agency also has made a number of minor

revisions to its original ROPS standards. OSHA believes that these

minor revisions will improve comprehension of, and compliance with, the

reinstated standards without making substantive revisions.

The following section highlights the substantive differences

between its original ROPS testing requirements and the testing

provisions of the consensus standards referenced in its current ROPS

construction and agriculture standards. The Agency describes in section

II.C below the minor revisions it is making to the original OSHA ROPS

standards under this direct final rule.

B. Substantive Differences Between the Standards

Construction standards. In revising the ROPS standards for

construction in the 1996 technical amendment, the Agency deleted

paragraphs (c) through (i) and (k) from 29 CFR 1926.1002, which

addressed testing of protective frames for wheel-type tractors used in

construction, and replaced them with a reference to Society of

Automotive Engineers (``SAE'') consensus standard J334a-1970 in

paragraph (a)(1) of revised 29 CFR 1926.1002. The Agency also revised

29 CFR 1926.1003, specifying testing requirements for overhead

protection used with tractors, by removing paragraphs (c) through (g)

and substituting a reference to SAE consensus standard J167-1970 in

paragraph (a)(1) of the revised standard.

While most of the revisions to the construction ROPS standards made

in the 1996 technical amendment were nonsubstantive, the Agency

identified two substantive revisions. The first revision involved

paragraph (c)(1) of original 29 CFR 1926.1002, which allowed the regulated

community to use either a laboratory test or a field test for impact testing,

while the SAE standard requires both tests. Accordingly, this direct final

rule reinstates the impact-testing option provided by paragraph (c)(1)

of original 29 CFR 1926.1002, and which is not available in the SAE

standard. (See Ex. 4-1.)

The second revision addressed paragraphs (i)(ii) of original 29 CFR

1926.1002 and (f)(1) of original 29 CFR 1926.1003, in combination with

paragraph (f)(2)(iv) of 29 CFR 1926.1001. These paragraphs permitted

manufacturers to conduct the required performance tests using either

zero-degree Fahrenheit (0 [deg]F) testing or Charpy V-notch testing,

while the SAE standard specifies that performance tests must be

conducted only at 0 [deg]F.\2\ Therefore, reinstating the original OSHA

standards will provide an additional cold-temperature testing option

not available in the SAE standard. (See Exs. 4-1 and 4-2.)

---------------------------------------------------------------------------

\2\ These two tests determine, under controlled laboratory

conditions, the reduced-temperature ductility of the carbon steel

used to make ROPS. Generally, the less ductile the steel, the more

likely it is to fracture with impact during reduced-temperature

exposure (thereby losing its protective features). The 0 [deg]F

test, used principally by ROPS manufacturers, involves administering

impacts and/or loads to the entire ROPS at 0 [deg]F, while the

Charpy V-notch test, used primarily by steel manufacturers, applies

impacts to steel specimens of a predetermined size at several

reduced-temperature levels.

---------------------------------------------------------------------------

Agriculture standards. In revising the ROPS standards for the

agriculture industry, the Agency deleted entirely original 29 CFR

1928.52 and 1928.53, as well as Appendix B to subpart C of 29 CFR part

1928. The deleted standards specified procedures for testing,

respectively, protective frames and enclosures for wheel-type tractors

used in agriculture, while Appendix B provided diagrams depicting these

testing procedures. In place of these requirements, OSHA referenced SAE

consensus standard J334a-1970 and American Society of Agricultural

Engineers (``ASAE'') consensus standard S306.3-1974 for protective

frames, and SAE consensus standard J168-1970 and ASAE consensus

standard S336.1-1974 for protective enclosures, in paragraph (b)(1) of

revised 29 CFR 1928.51.

For both protective frames and protective enclosures, the testing

conducted under the ASAE and SAE standards generally is consistent with

the testing requirements of the original OSHA standards. However, the

Agency found several substantive differences between the original OSHA

standards and the consensus standards (for testing both protective

frames and protective enclosures) that replaced them. First, both the

original OSHA standards and the ASAE standards differ substantively

from the SAE standards by providing an exemption from field-upset

testing based on results for either the static or dynamic versions of

the laboratory energy-absorption test,\3\ while the SAE standards

require field-upset testing only under dynamic test conditions.

Consequently, this direct final rule will reinstate the testing

exemption found in the original OSHA ROPS standards. (See Exs. 4-3 and

4-4.) Second, the original OSHA and the SAE standards allow either

static or dynamic testing at 0 [deg]F, while the ASAE standards limit

testing at 0 [deg]F to dynamic testing. Therefore, reinstating the

original OSHA standards under this direct final rule restores the

testing option found in the original OSHA standards, but which is not

in the ASAE standards. (See Exs. 4-3 and 4-4.) Finally, as an

alternative to 0 [deg]F testing, the original OSHA and ASAE standards

offer the Charpy V-notch test, while the SAE standards do not.

Accordingly, reinstating the original OSHA standard will provide an

additional cold-temperature testing option not available in the SAE

standards. (See Exs. 4-3 and 4-4.)

---------------------------------------------------------------------------

\3\ The laboratory energy-absorption test assesses the energy

(measured as force multiplied by distance) absorbed by ROPS during

laboratory-controlled rear and side impacts. During testing, ROPS

components bend as they absorb energy; however, such bending must

not exceed the deflection values specified by the OSHA standards

(these values represent thresholds beyond which the deflection may

endanger the tractor operator). Generally, the tests have a safety

margin (e.g., 15%), which means that additional deflection equal to

the specified safety margin is possible without jeopardizing safety.

The laboratory-based test is derived from the energy-absorbing

results obtained for ROPS tested during rear or side field-upset

tests, i.e., deflection values are comparable when the same ROPS and

tractors are evaluated under the two testing conditions.

---------------------------------------------------------------------------

C. Minor Revisions to the Original OSHA ROPS Standards

Paragraph (c)(1) of OSHA's original 29 CFR 1926.1002 contains an

editorial error. The original paragraph states that laboratory or field

tests ``determine the performance requirements set forth in paragraph

(c)(1) of this [standard].'' However, paragraph (i) of the standard,

not paragraph (c)(1), provides the performance requirements that the

tests must determine. Therefore, OSHA is correcting the reference

accordingly.

The Agency also is making two additional revisions related to the

original construction standards for ROPS. First, as noted in Ex. 4-1,

paragraph 5.3.2 of SAE consensus standard J334a-1970 defines the term

``Pu'' as the ``[u]ltimate force capacity of mounting

connection, lb (kg).'' However, paragraph (j)(3) of original 29 CFR

1926.1002 lists no definition for this term. Since the original OSHA

standard duplicates the remaining terminology of the SAE consensus

standard, this rulemaking will add this term and the SAE consensus

standard definition to reinstated 29 CFR 1926.1002(j)(3). Second, in

reinstating the original 29 CFR 1926.1002 and 1926.1003 standards, OSHA

is removing the following sentence from paragraphs (k) and (g) of these

respective standards: ``The SAE standard shall be used in the event

that questions of interpretation arise.'' The Agency is removing this

sentence because the referenced SAE standard provides no additional

information on which to base such interpretations.

Finally, the Agency is making a number of plain-language revisions

to the regulatory text of the original OSHA ROPS standards for the

construction and agriculture industries. The Agency finds that using

plain language will improve the comprehensibility of these provisions.

These improvements will, in turn, enhance employer compliance with the

revised provisions and, concomitantly, increase the protection afforded

to employees. OSHA believes that rewriting these provisions in plain

language did not alter the substantive requirements of the existing

provisions.

III. Procedural Determinations

A. Legal Considerations

The purpose of the Occupational Safety and Health Act of 1970

(``OSH Act''), 29 U.S.C. 651 et seq., is ``to assure so far as possible

every working man and woman in the nation safe and healthful working

conditions and to preserve our human resources.'' (29 U.S.C. 651(b).)

To achieve this goal, Congress authorized the Secretary of Labor to

promulgate and enforce occupational safety and health standards. (29

U.S.C. 655(b) and 654(b).) A safety or health standard is a standard

``which requires conditions, or the adoption or use of one or more

practices, means, methods, operations, or processes, reasonably

necessary or appropriate to provide safe or healthful employment or

places of employment.'' (29 U.S.C. 652(8).) A standard is reasonably

necessary or appropriate within the meaning of Section 652(8) when a

significant risk of material harm exists in the workplace and the

standard will reduce substantially or eliminate that workplace risk.

OSHA based its original ROPS standards on evidence that these

structures are necessary to ensure proper employee protection should

wheel-type tractors become unstable and roll backwards or to the side.

For this direct final rule, the Agency has determined that the original

OSHA construction and agriculture ROPS standards meet the statutory

requirements of Section 652(8) of the OSH Act. In addition, OSHA finds

that this direct final rule does not increase employers' compliance

burdens (see section B (``Economic Analysis and Regulatory Flexibility

Certification'') below). Consequently, it is unnecessary to determine

significant risk, or the extent to which the direct final rule would

reduce that risk, as would typically be required by Industrial Union

Department, AFL-CIO v. American Petroleum Institute, 448 U.S. 607

(1980).

Because OSHA replaced its original ROPs testing provisions through

a technical amendment, the regulated community did not have an

opportunity for notice and comment on the substantive differences

between the original ROPs testing provisions and the consensus

standards that replaced them. Such notice and comment are required by

the Administrative Procedures Act (5 U.S.C. 553(b)), the Occupational

Safety and Health Act of 1970 (29 U.S.C. 655(b)(2) and (b)(3)), and

OSHA's procedural regulations (29 CFR 1911.5). Therefore, the Agency

has concluded that it has a legal obligation to the regulated community

to reinstate the original OSHA standards through this direct final

rule.

B. Economic Analysis and Regulatory Flexibility Certification

OSHA's Economic Analysis and Regulatory Flexibility Analysis

address issues related to the costs, benefits, technological

feasibility, and economic impacts (including small business impacts) of

this direct final rule reinstating the Agency's original ROPS

standards.

Executive Order (``E.O.'') 12866 requires regulatory agencies to

conduct an economic analysis for rules that meet certain criteria. The

most frequently used criterion under E.O. 12866 is that the rule will

have an annual cost impact on the economy of $100 million or more.

Neither the benefits nor the costs of this direct final rule exceed

$100 million. Nevertheless, the Agency has prepared this economic

analysis to summarize this direct final rule's impact, and has

concluded that it is not an economically significant regulatory action

under E.O. 12866.

Although this direct final rule applies to employers in

construction and agriculture so that their employees may operate safe

equipment (i.e., wheel-type tractors), it more directly affects

equipment manufacturers. Equipment manufacturers design and build

machines that have ROPS to meet the testing criteria specified in

OSHA's ROPS standards. Fewer than 10 original equipment manufacturers

are directly affected by this direct final rule (see Ex. 4-5).

Employers in the construction and agriculture industries who purchase

and use wheel-type tractors are in violation of OSHA's ROPS standards

and are subject to penalty when the tractors do not have protective

structures meeting these standards. Therefore, employers in the

construction and agriculture industries would be affected indirectly if

changing the ROPS testing procedures were to change the price of

equipment.

For the purposes of its economic analyses, OSHA generally defines

small firms as firms with fewer than 1,000 employees (using the Small

Business Administration's definition); however, the Agency may use

smaller size categories as well. None of the original equipment

manufacturers affected by this direct final rule is a small employer

under any of these definitions. However, some small manufacturing firms

(e.g., with fewer than 20 employees) may retrofit older, existing

equipment with custom-made ROPS, and these firms may be affected by

this direct final rule.

As explained in the preamble above, this direct final rule provides

equipment manufacturers with more options for testing ROPS than the

current OSHA ROPS standards. Therefore, none of the provisions in the

direct final rule impose conditions that would generate new costs for

equipment manufacturers, including small manufacturing firms. Cost

savings under the direct final rule, if any, depend on the extent that

equipment manufacturers choose to avail themselves of its alternative

provisions. The Agency has not quantified the benefit of the increased

testing options to manufacturers. The reinstated standards are both

technologically and economically feasible and do not impose new

compliance costs on equipment manufacturers or on the construction and

agriculture industries. The Agency concludes that the economic impact

of the direct final rule will be negligible on any of the potentially

affected industries, including potentially affected small employers.

The Regulatory Flexibility Act of 1980 (``RFA''), as amended by the

Small Business Regulatory Enforcement Fairness Act of 1996 (5 U.S.C.

601 et seq.), requires regulatory agencies to determine whether

regulatory actions will adversely affect small entities. OSHA's

threshold criteria for identifying a significant impact include costs

exceeding one percent of revenues or five percent of profits. When

costs exceed either threshold, then the Agency considers the impact on

small entities to be significant for purposes of complying with the

RFA. Employers will incur no significant costs of complying with this

direct final rule. Accordingly, OSHA certifies that this regulation

will not have a significant impact on a substantial number of small

entities. In addition, the direct final rule is not a major rule as

defined by Section 804 of the Congressional Review Act (5 U.S.C. 801 et

seq.).

C. Paperwork Reduction Act

After analyzing the provisions of this direct final rule in terms

of the Paperwork Reduction Act of 1995 (44 U.S.C. 3501 et seq. and 5

CFR part 1320), OSHA has determined that these provisions do not impose

any collection-of-information (i.e., ``paperwork'') requirements on

employers in the construction and agriculture industries who use ROPS

to protect employees who operate wheel-type tractors. While several of

the provisions reinstated by this direct final rule require that test

data be recorded or verified (i.e., 29 CFR 1926.1002(d)(3), (d)(6),

(g)(2)(i), (g)(2)(ii), and (g)(2)(iii); 1928.52(d)(2)(iii)(A) and

(d)(2)(iii)(F); and 1928.53(d)(1)(iii) and (d)(2)(iii)(B)), these

information-collection requirements apply only to ROPS manufacturers,

not to the employers who use ROPS on wheel-type tractors. OSHA also

concludes that, as a matter of usual and customary business practice,

manufacturers record and verify ROPS testing information to ensure the

integrity of protective frames and enclosures, and notes that the

current SAE and ASAE consensus standards for ROPS require that

manufacturers record and verify ROPS test data.

Members of the public may send comments on this paperwork

determination to: Office of Information and Regulatory Affairs

(Attention: Desk Officer for OSHA), OMB, Room 10235, 726 Jackson Place,

NW., Washington, DC 20503. However, no comment received on this

paperwork determination will be considered by the Agency to be a

``significant adverse comment'' as specified above under section I

(``Direct Final Rulemaking'').

D. Federalism

The Agency reviewed the direct final rule according to the most

recent Executive Order (``E.O.'') on Federalism (Executive Order 13132,

64 FR 43225, August 10, 1999). This E.O. requires that Federal

agencies, to the extent possible, refrain from limiting State policy

options, consult with States before taking actions that restrict their

policy options, and take such actions only when clear constitutional

authority exists and the problem is national in scope. The E.O. allows

Federal agencies to preempt State law only with the expressed consent

of Congress. In such cases, Federal agencies must limit preemption of

State law to the extent possible.

Under Section 18 of the Occupational Safety and Health Act of 1970

(``OSH Act''; 29 U.S.C. 651 et seq.), Congress expressly provides OSHA

with authority to preempt State occupational safety and health

standards. Under the OSH Act, a State can avoid preemption under

Section 18 only when it submits, and obtains Federal approval of, a

plan for the development and enforcement of safety and health standards

(i.e., ``State-Plan State''; see 29 U.S.C. 667). Occupational safety

and health standards developed by a State-Plan State must be at least

as effective in providing safe and healthful employment and places of

employment as the Federal standards. Subject to these requirements, a

State-Plan State is free to develop and enforce under State law its own

requirements for safety and health standards.

The Agency concludes that this direct final rule complies with E.O.

13132. In States without OSHA-approved State Plans, Congress expressly

provides for OSHA standards to preempt State job safety and health

rules in areas addressed by Agency standards; in these States, the

direct final rule limits State policy options in the same manner as

every Agency standard. In States with OSHA-approved State Plans, this

action does not significantly limit State policy options.

E. State-Plan States

When Federal OSHA promulgates a new standard or imposes additional

or more stringent requirements than an existing standard, the 26 States

and U.S. Territories with their own OSHA-approved occupational safety

and health plans must revise their standards to reflect the new

standard or amendment, or show the Agency why such action is

unnecessary, e.g., because an existing State standard covering this

area already is at least as effective as the new Federal standard or

amendment (29 U.S.C. 553.5(a)). The State standard must be at least as

effective as the final Federal rule, must be applicable to both the

private and public (i.e., State and local government employees)

sectors, and must be completed within six months of the publication

date of the final Federal rule. When OSHA promulgates a new standard or

amendment that does not impose additional or more stringent

requirements than an existing standard, States are not required to

revise their standards, although the Agency may encourage them to do

so. The 26 States and Territories with OSHA-approved State plans are:

Alaska, Arizona, California, Hawaii, Indiana, Iowa, Kentucky, Maryland,

Michigan, Minnesota, Nevada, New Mexico, North Carolina, Oregon, Puerto

Rico, South Carolina, Tennessee, Utah, Vermont, Virginia, Washington,

and Wyoming. Connecticut, New Jersey, New York, and the Virgin Islands

have OSHA-approved State plans that apply to State and local government

employees only. Although this direct final rule does not impose any

additional or more stringent requirements on employers compared to the

existing standard, the Agency strongly encourages the States and

Territories with their own State Plans that currently do not include

the original OSHA ROPS testing standards in their construction and

agriculture standards to adopt the revisions promulgated under this

direct final rule within six months of the date of this Federal

Register notice, unless OSHA withdraws the Direct Final Rule following

the end of the comment period.

F. Unfunded Mandates Reform Act

OSHA has reviewed this direct final rule according to the Unfunded

Mandates Reform Act of 1995 (``UMRA''; 2 U.S.C. 1501 et seq.) and

Executive Order 12875. As discussed above in section III.B (``Final

Economic Analysis and Regulatory Flexibility Certification'') of this

preamble, the Agency has determined that this direct final rule imposes

no additional costs on any private-or public-sector entity.

Accordingly, this direct final rule requires no additional expenditures

by either public or private employers.

As noted earlier, the Agency's standards do not apply to State and

local governments, except in States that have voluntarily elected to

adopt a State plan approved by the Agency. Consequently, this direct

final rule does not meet the definition of a ``Federal

intergovernmental mandate'' (see Section 421(5) of the UMRA (2 U.S.C.

658(5)). In conclusion, this direct final rule does not mandate that

State, local, and tribal governments adopt new, unfunded regulatory

obligations.

G. Public Participation

The Agency requests that interested members of the public who

submit written comments concerning this direct final rule do so using

any of the methods listed above in the section titled Addresses. Note,

however, that the Agency has defined a significant adverse comment as

only those comments that address: (1) The lawfulness of the procedures

used to promulgate the 1996 technical amendment as these procedures

relate to the ROPs testing provisions; or (2) whether the minor

revisions made to the original ROPS standards in this direct final rule

are reasonable or appropriate.

OSHA will post all comments received, without revision, to http://dockets.osha.gov,

including any personal information provided. The Agency cautions commenters

about submitting personal information such as social security numbers

and birth dates. For access to materials in the docket, including background

documents and comments received, go to http://dockets.osha.gov. Contact

the OSHA Docket Office for information about materials not available

through the OSHA webpage, and for assistance in using the webpage to

locate docket submissions.

If the Agency receives no significant adverse comment regarding

this direct final rule, it will publish a Federal Register notice

confirming the effective date of this direct final rule. For the

purpose of judicial review, OSHA views the date that it confirms the

effective date of the direct final rule to be the date of issuance.

Additionally, such confirmation may include minor stylistic or

technical changes to the regulatory language provided by this notice.

If OSHA receives significant adverse comment on this direct final rule,

it will withdraw the direct final rule and determine, based on the

comments submitted to the record, whether to issue a proposed rule in

the future.

List of Subjects

29 CFR Part 1926

Construction industry, Incorporation by reference, Motor vehicle

safety, Occupational safety and health.

29 CFR Part 1928

Agriculture, Incorporation by reference, Motor vehicle safety,

Occupational safety and health.

Authority and Signature

Jonathan L. Snare, Acting Assistant Secretary of Labor for

Occupational Safety and Health, U.S. Department of Labor, 200

Constitution Avenue, NW., Washington, DC 20210 authorized the

preparation of this direct final rule. The Agency is issuing this

direct final rule under the following authorities: Sections 4, 6, and 8

of the Occupational Safety and Health Act of 1970 (29 U.S.C. 653, 655,

657); Section 3704 of the Contract Work Hours and Safety Standards Act

(40 U.S.C. 3701 et seq.); Secretary of Labor's Order No. 5-2002 (67 FR

65008); and 29 CFR part 1911.

Signed at Washington, DC on December 13, 2005.

Jonathan L. Snare,

Acting Assistant Secretary of Labor.

IV. Amended Standards

0

Based on the reasons presented in the preamble to this direct final

rule, OSHA is amending 29 CFR parts 1926 and 1928 as follows:

PART 1926--[AMENDED]

Subpart W--[Amended]

0

1. Revise the authority citation for subpart W of part 1926 to read as

follows:

Authority: Section 3704 of the Contract Work Hours and Safety

Standards Act (40 U.S.C. 3701); Sections 4, 6, and 8 of the

Occupational Safety and Health Act of 1970 (29 U.S.C. 653, 655,

657); and Secretary of Labor's Order No. 12-71 (36 FR 8754), 8-76

(41 FR 25059), 9-83 (48 FR 35736), 1-90 (55 FR 9033), 6-96 (62 FR

111), 3-2000 (65 FR 50017), or 5-2002 (67 FR 65008), as applicable.

0

2. Revise Sec. Sec. 1926.1002 and 1926.1003 and add a new Appendix A

to subpart W, to read as follows:

Sec. 1926.1002 Protective frames (roll-over protective structures,

known as ROPS) for wheel-type agricultural and industrial tractors used

in construction.

(a) General. (1) The purpose of this section is to set forth

requirements for frames used to protect operators of wheel-type

agricultural and industrial tractors that will minimize the possibility

of operator injury resulting from accidental upsets during normal

operation. With respect to agricultural and industrial tractors, the

provisions of 29 CFR 1926.1001 and 1926.1003 for rubber-tired dozers

and rubber-tired loaders may be used instead of the requirements of

this section.

(2) The protective frame that is the subject of this standard is a

structure mounted to the tractor that extends above the operator's seat

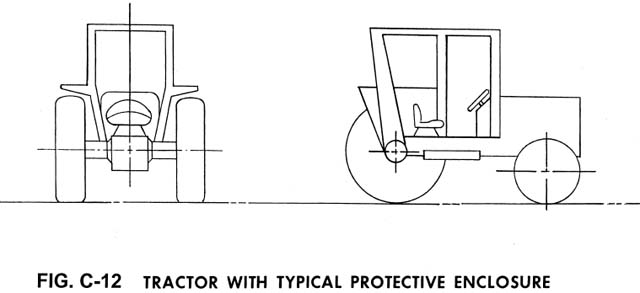

and conforms generally to Figure W-14.

(3) When an overhead weather shield is attached to the protective

frame, it may be in place during testing, provided that it does not

contribute to the strength of the protective frame. When such an

overhead weather shield is attached, it must meet the requirements of

paragraph (i) of this section.

(4) For overhead protection requirements, see 29 CFR 1926.1003.

(5) The following provisions address requirements for protective

enclosures.

(i) When protective enclosures are used on wheel-type agricultural

and industrial tractors, they shall meet the requirements of Society of

Automotive Engineers (``SAE'') standard J168-1970 (``Protective

enclosures--test procedures and performance requirements''), which is

incorporated by reference. The incorporation by reference was approved

by the Director of the Federal Register in accordance with 5 U.S.C.

552(a) and 1 CFR part 51.

(ii) SAE standard J168-1970 appears in the 1971 SAE Handbook, or it

may be examined at: any OSHA Regional Office; the OSHA Docket Office,

U.S. Department of Labor, 200 Constitution Avenue, NW., Room N-2625,

Washington, DC 20210 (telephone: (202) 693-2350 (TTY number: (877) 889-

5627)); or the National Archives and Records Administration (``NARA'').

(For information on the availability of this material at NARA,

telephone (202) 741-6030 or access the NARA Web site at

http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html.

) Copies may be purchased from the Society of Automotive

Engineers, 400 Commonwealth Drive, Warrendale, Pennsylvania 15096-0001.

(b) Applicability. The requirements of this section apply to wheel-

type agricultural and industrial tractors used in construction work.

See paragraph (j) of this section for definitions of agricultural

tractors set forth in paragraph (i) of this section.

(c) Performance requirements. (1) Either a laboratory test or a

field test is required to determine the performance requirements set

forth in paragraph (i) of this section.

(2) A laboratory test may be either static or dynamic. The

laboratory test must be under conditions of repeatable and controlled

loading to permit analysis of the protective frame.

(3) A field-upset test, when used, shall be conducted under

reasonably controlled conditions, both rearward and sideways to verify

the effectiveness of the protective frame under actual dynamic

conditions.

(d) Test procedures--general. (1) The tractor used shall be the

tractor with the greatest weight on which the protective frame is to be

used.

(2) A new protective frame and mounting connections of the same

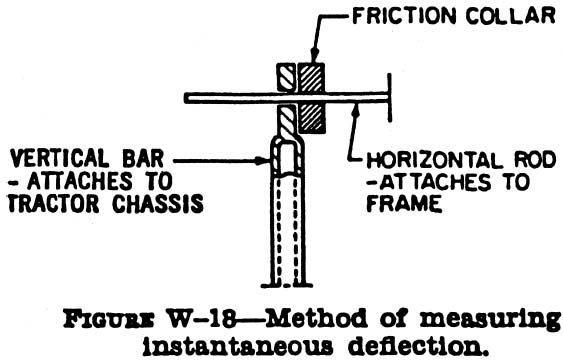

design shall be used for each test procedure.

(3) Instantaneous and permanent frame deformation shall be measured

and recorded for each segment of the test.

(4) Dimensions relative to the seat shall be determined with the

seat unloaded and adjusted to its highest and most rearward latched

position provided for a seated operator.

(5) When the seat is offset, the frame loading shall be on the side

with the least space between the centerline of the seat and the

upright.

(6) The low-temperature impact strength of the material used in the

protective structure shall be verified by suitable material tests or

material certifications according to 29 CFR 1926.1001(f)(2)(iv).

(e) Test procedure for vehicle overturn. (1) Vehicle weight. The

weight of the tractor, for purposes of this section, includes the

protective frame, all fuels, and other components required for normal

use of the tractor. Ballast must be added when necessary to achieve a

minimum total weight of 130 lb (59 kg) per maximum power-takeoff

horsepower at the rated engine speed. The weight of the front end must

be at least 33 lb (15 kg) per maximum power-takeoff horsepower. In case

power-takeoff horsepower is unavailable, 95 percent of net engine

flywheel horsepower shall be used.

(2) Agricultural tractors shall be tested at the weight set forth

in paragraph (e)(1) of this section.

(3) Industrial tractors shall be tested with items of integral or

mounted equipment and ballast that are sold as standard equipment or

approved by the vehicle manufacturer for use with the vehicle when the

protective frame is expected to provide protection for the operator

with such equipment installed. The total vehicle weight and front-end

weight as tested shall not be less than the weights established in

paragraph (e)(1) of this section.

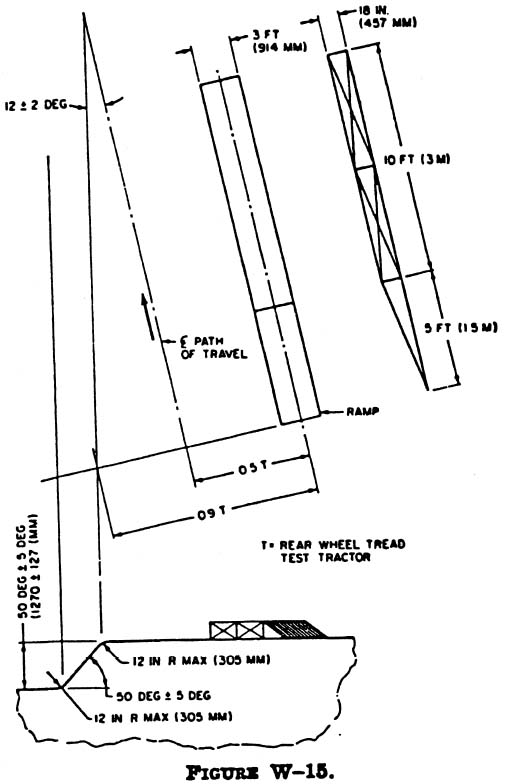

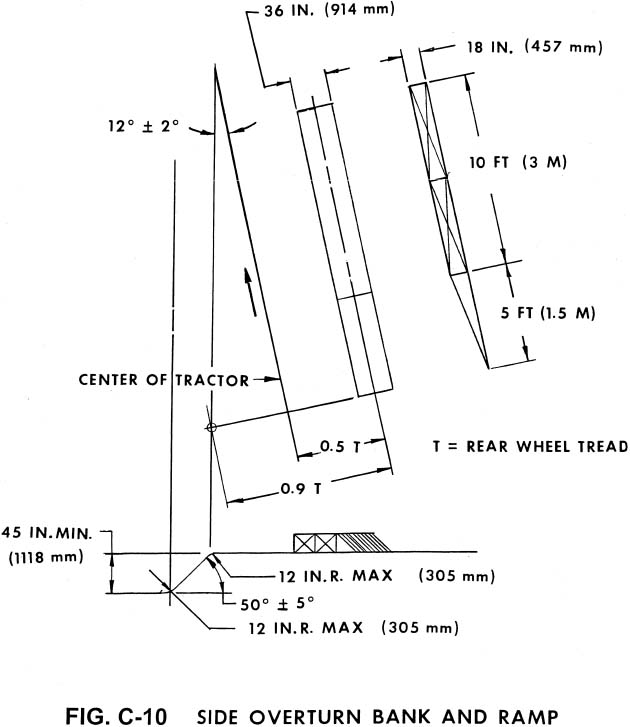

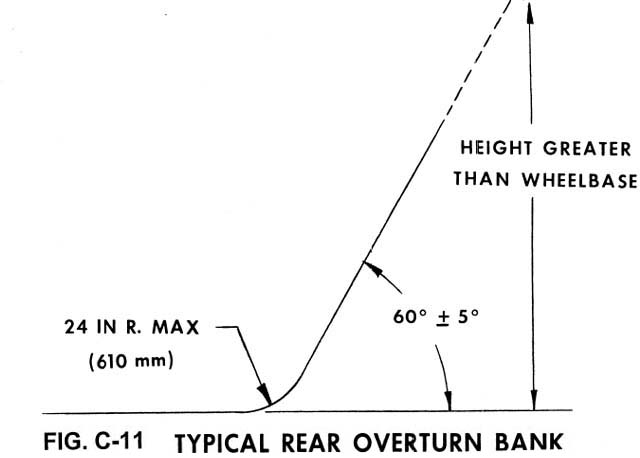

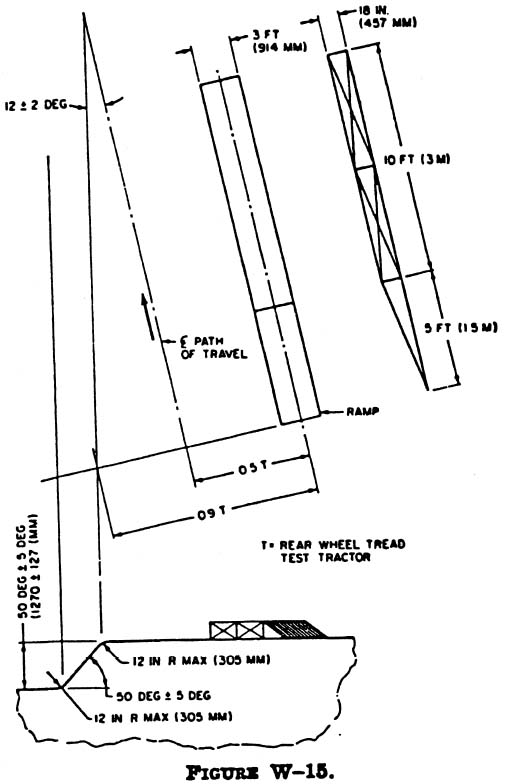

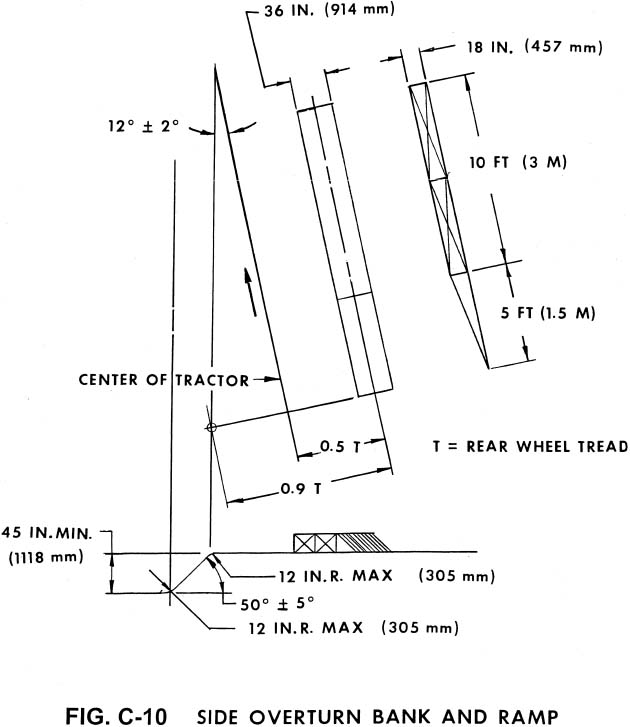

(4) The following provisions address soil bank test conditions.

(i) The test shall be conducted on a dry, firm soil bank as

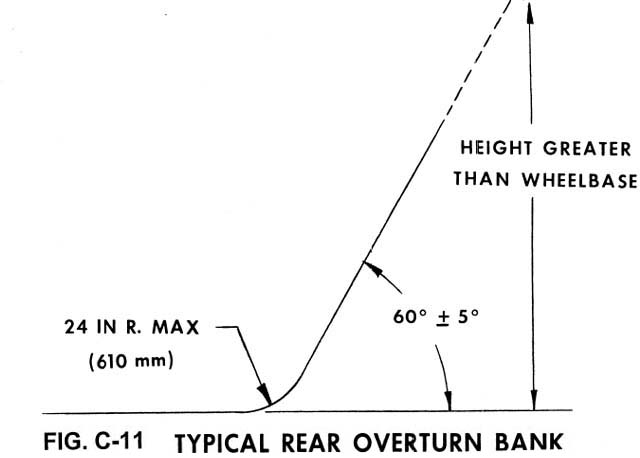

illustrated in Figure W-15. The soil in the impact area shall have an

average cone index in the 0-in. to 6-in. (0-mm to 153-mm) layer not

less than 150 according to American Society of Agricultural Engineers

(``ASAE'') recommendation ASAE R313.1-1971 (``Soil cone penetrometer''),

as reconfirmed in 1975, which is incorporated by reference. The

incorporation by reference was approved by the Director of the Federal

Register in accordance with 5 U.S.C. 552(a) and 1 CFR part 51. The path

of vehicle travel shall be 12[deg] 2[deg] to the top edge of the bank.

(ii) ASAE recommendation ASAE R313.1-1971, as reconfirmed in 1975,

appears in the 1977 Agricultural Engineers Yearbook, or it may be

examined at: any OSHA Regional Office; the OSHA Docket Office, U.S.

Department of Labor, 200 Constitution Avenue, NW., Room N-2625,

Washington, DC 20210 (telephone: (202) 693-2350 (TTY number: (877) 889-

5627)); or the National Archives and Records Administration (``NARA'').

(For information on the availability of this material at NARA,

telephone (202) 741-6030 or access the NARA Web site at

http://www.archives.gov/federal_register/code_of_federal_regulations/ibr_locations.html).

Copies may be purchased from the American Society of Agricultural Engineers

2950 Niles Road, St. Joseph, MI 49085.

(5) The upper edge of the bank shall be equipped with an 18-in.

(457-mm) high ramp as described in Figure W-15 to assist in tipping the

vehicle.

(6) The front and rear wheel-tread settings, when adjustable, shall

be at the position nearest to halfway between the minimum and maximum

settings obtainable on the vehicle. When only two settings are

obtainable, the minimum setting shall be used.

(7) Vehicle overturn test--sideways and rearward. (i) The tractor

shall be driven under its own power along the specified path of travel

at a minimum speed of 10 mph (16 kph), or maximum vehicle speed when

under 10 mph (16 kph), up the ramp as described in paragraph (d)(5) of

this section to induce sideways overturn.

(ii) Rear upset shall be induced by engine power with the tractor

operating in gear to obtain 3 to 5 mph (4.8 to 8 kph) at maximum

governed engine rpm, preferably by driving forward directly up a

minimum slope of two vertical to one horizontal. The engine clutch may

be used to aid in inducing the upset.

(f) Other test procedures. When the field-upset test is not used to

determine ROPS performance, either the static test or the dynamic test,

contained in paragraph (g) or (h) of this section, shall be made.

(g) Static test. (1) Test conditions. (i) The laboratory mounting

base shall include that part of the tractor chassis to which the

protective frame is attached, including the mounting parts.

(ii) The protective frame shall be instrumented with the necessary

equipment to obtain the required load-deflection data at the locations

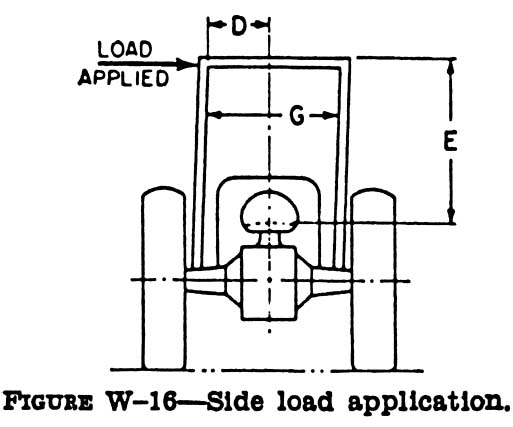

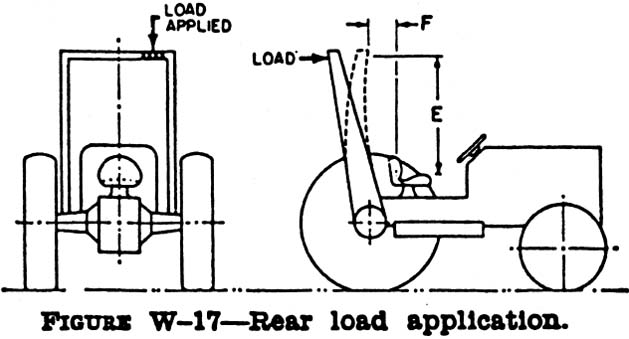

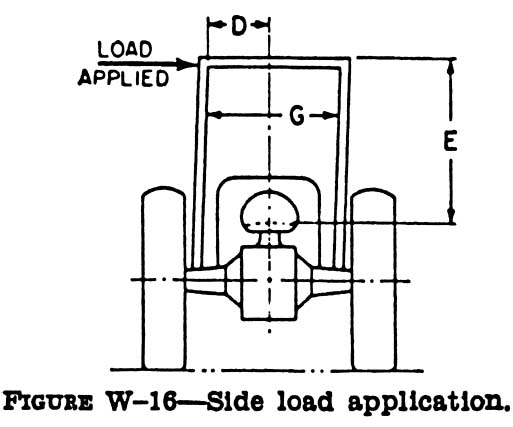

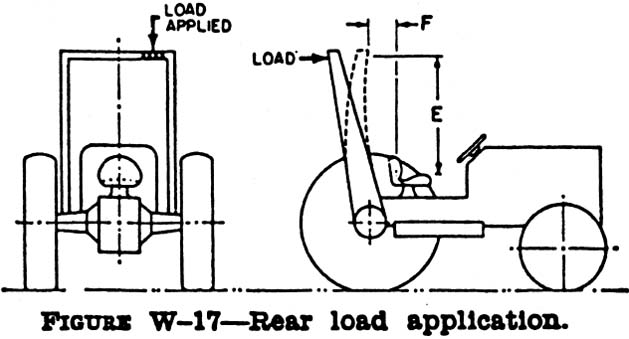

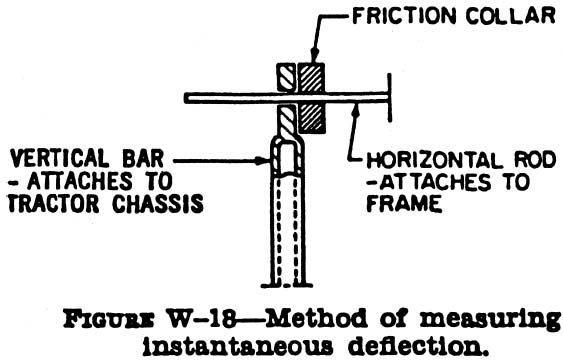

and directions specified in Figures W-16, W-17, and W-18.

(iii) The protective frame and mounting connections shall be

instrumented with the necessary recording equipment to obtain the

required load-deflection data to be used in calculating FSB (see

paragraph (j)(3) of this section). The gauges shall be placed on

mounting connections before the installation load is applied.

(2) Test procedure. (i) The side-load application shall be at the

upper extremity of the frame upright at a 90[deg] angle to the

centerline of the vehicle. The side load L shall be applied according

to Figure W-16. L and D shall be recorded simultaneously. The test

shall be stopped when:

(A) The strain energy absorbed by the frame is equal to the

required input energy (Eis);

(B) Deflection of the frame exceeds the allowable deflection; or

(C) The frame load limit occurs before the allowable deflection is

reached in the side load.

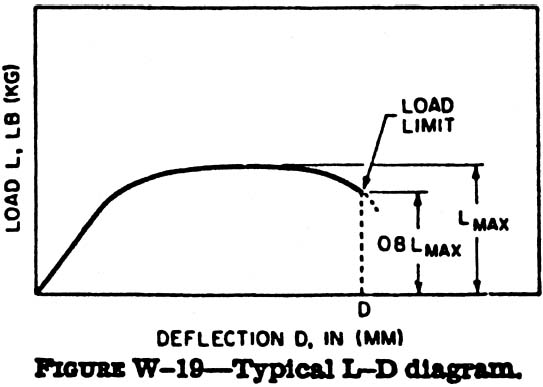

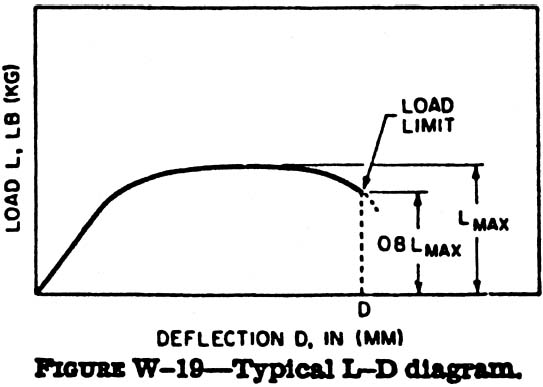

(ii) The L-D diagram (see Figure W-19 for an example) shall be

constructed using the data obtained according to paragraph (g)(2)(i) of

this section.

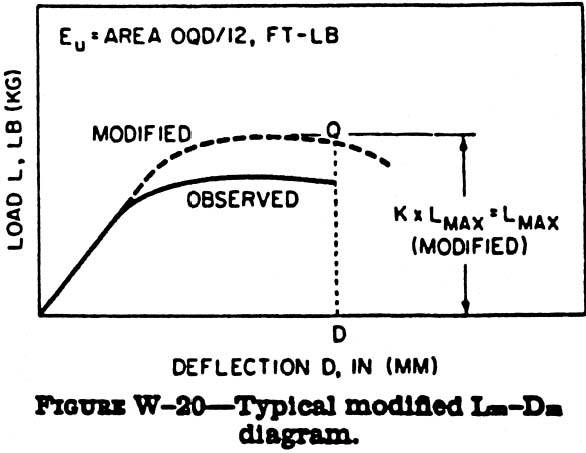

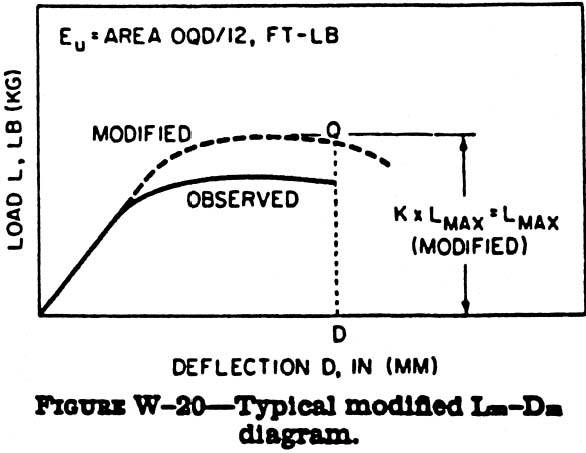

(iii) The modified Lm-Dm diagram shall be constructed according to

paragraph (g)(2)(ii) and Figure W-20 of this section. The strain energy

absorbed by the frame (Eu) shall then be determined.

(iv) Eis, FER, and FSB shall be calculated.

(v) The test procedure shall be repeated on the same frame using L

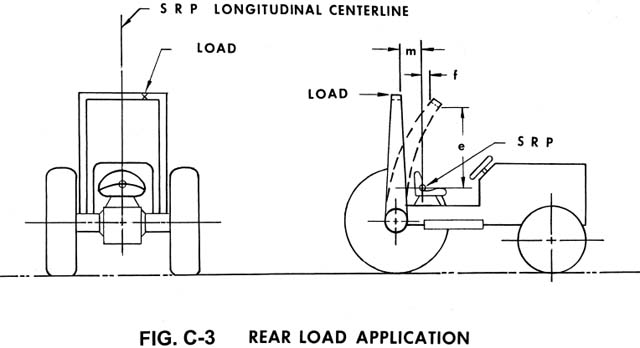

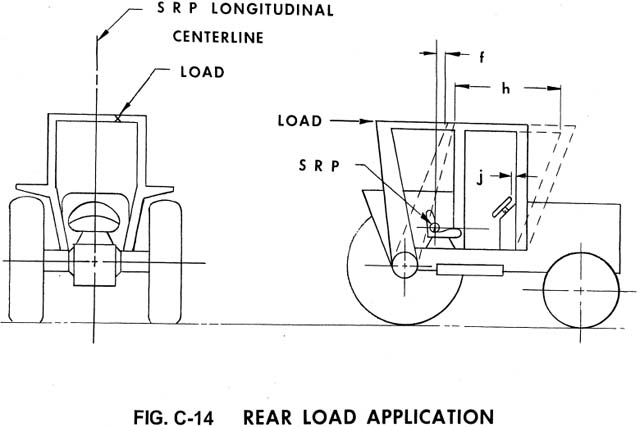

(rear input; see Figure W-18) and Eir. Rear-load application shall be

distributed uniformly along a maximum projected dimension of 27 in.

(686 mm) and a maximum area of 160 sq. in. (1,032 sq. cm) normal to the

direction of load application. The load shall be applied to the upper

extremity of the frame at the point that is midway between the

centerline of the seat and the inside of the frame upright.

(h) Dynamic test. (1) Test conditions. (i) The protective frame and

tractor shall meet the requirements of paragraphs (e)(2) or (3) of this

section, as appropriate.

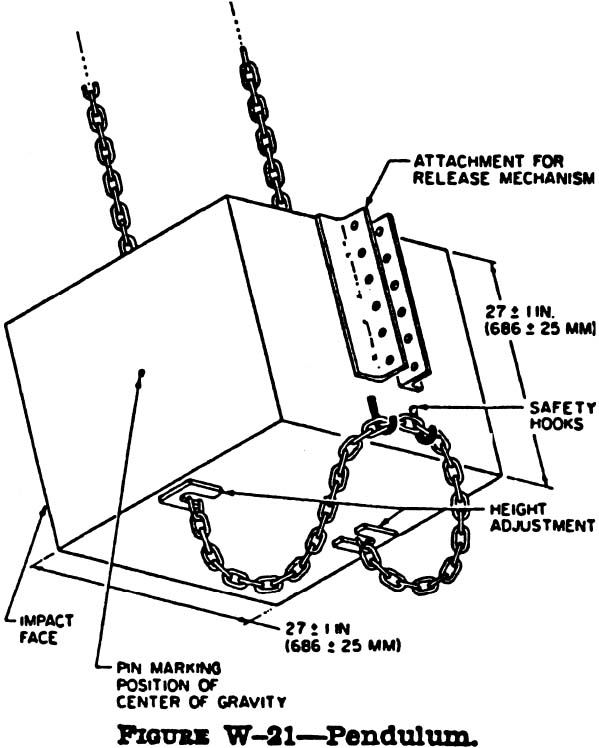

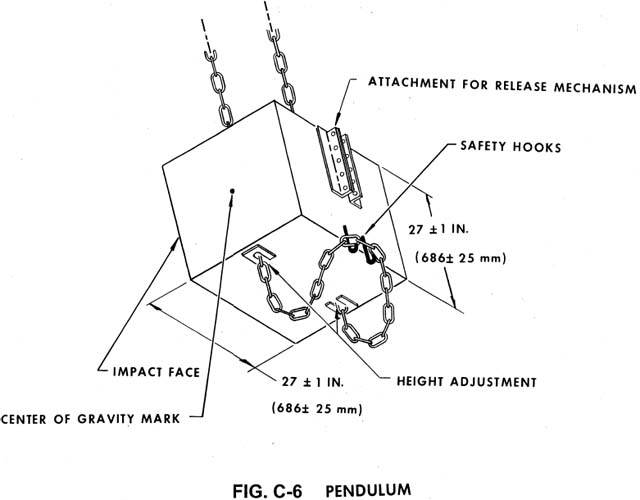

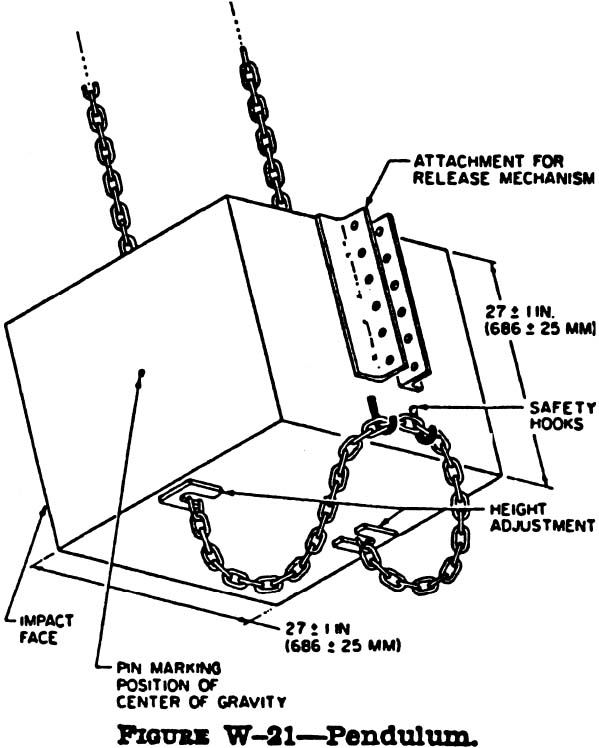

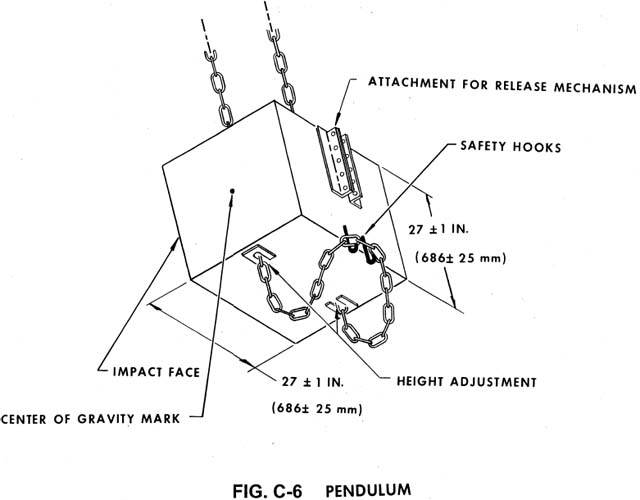

(ii) The dynamic loading shall be produced by using a 4,410-lb

(2,000-kg) weight acting as a pendulum. The impact face of the weight

shall be 27 1 in. by 27 1 in. (686 25 mm by 686 25 mm), and shall be constructed so

that its center of gravity is within 1.0 in. (25.4 mm) of its geometric

center. The weight shall be suspended from a pivot point 18 to 22 ft

(5.5 to 6.7 m) above the point of impact on the frame, and shall be

conveniently and safely adjustable for height (see Figure W-21).

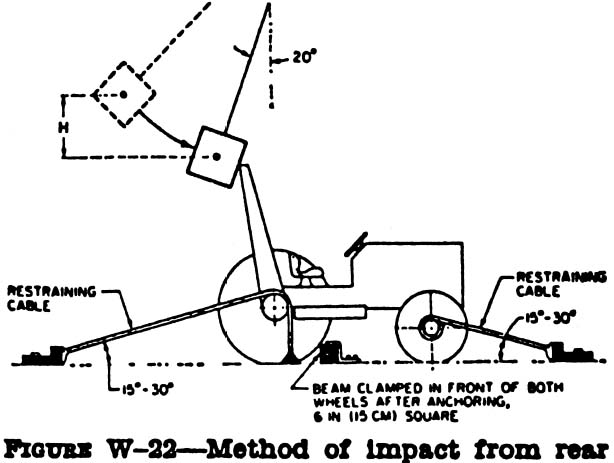

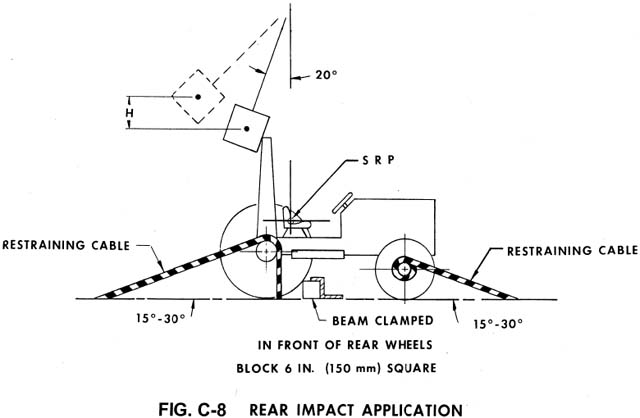

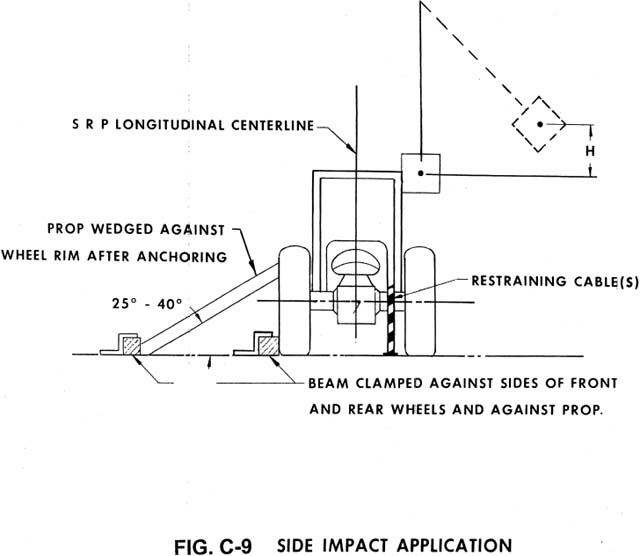

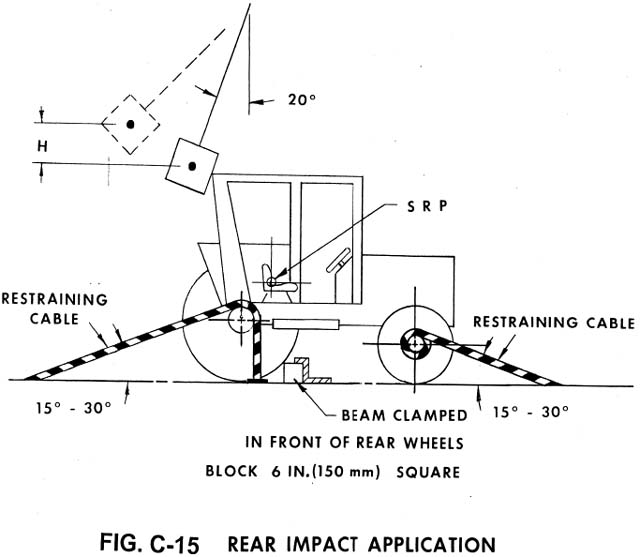

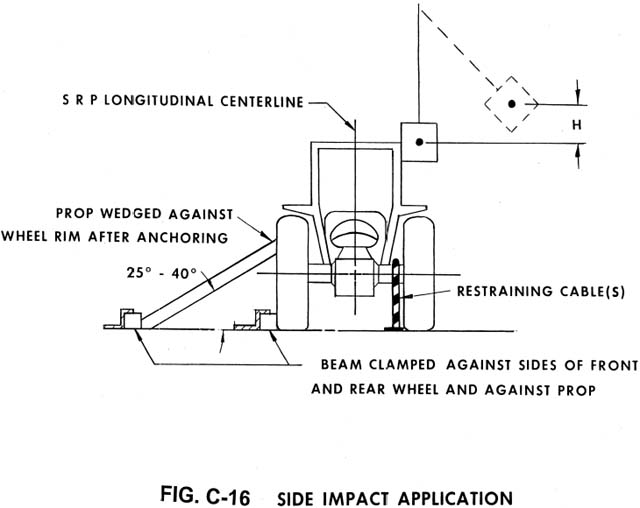

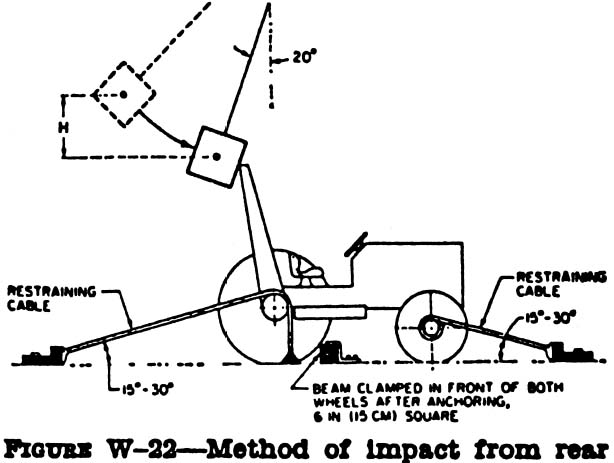

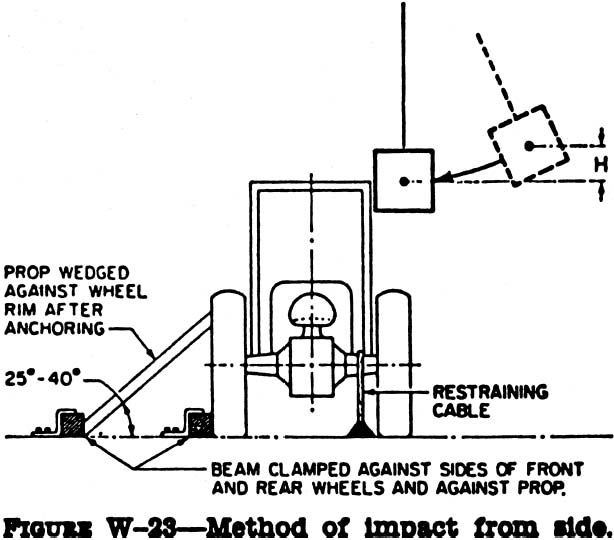

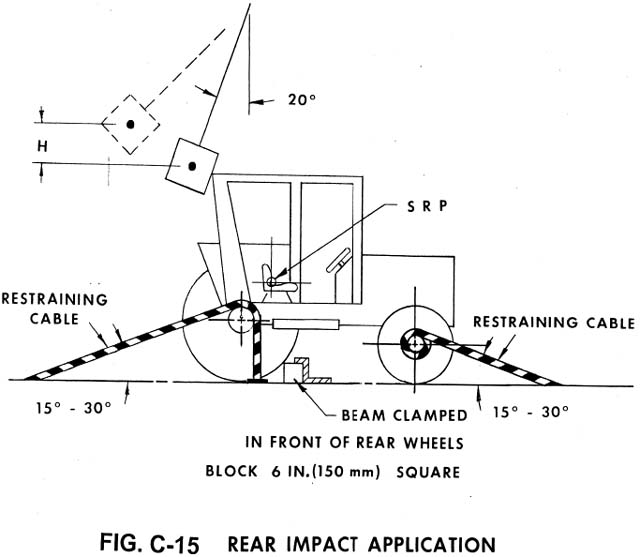

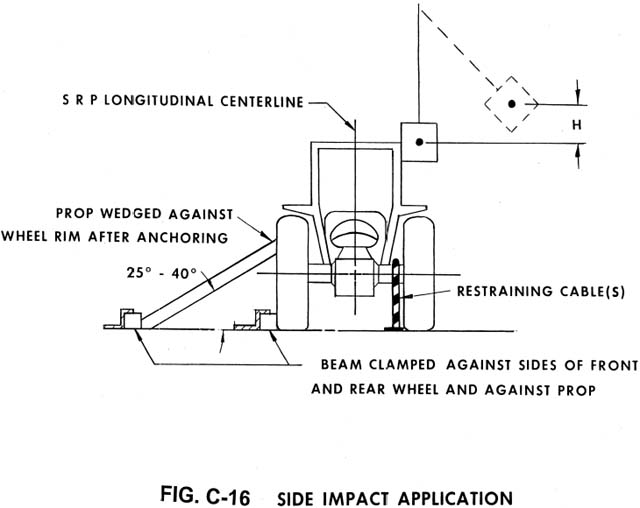

(iii) For each phase of testing, the tractor shall be restrained

from moving when the dynamic load is applied. The restraining members

shall be 0.50- to 0.63-in. (12.5- to 16.0-mm) steel cable, and points

for attaching restraining members shall be located an appropriate

distance behind the rear axle and in front of the front axle to provide

a 15[deg] to 30[deg] angle between the restraining cable and the

horizontal. The restraining cables shall either be in the plane in

which the center of gravity of the pendulum will swing, or more than

one restraining cable shall give a resultant force in this plane (see

Figure W-22).

(iv) The wheel-tread setting shall comply with the requirements of

paragraph (e)(6) of this section. The tires shall have no liquid

ballast, and shall be inflated to the maximum operating pressure

recommended by the tire manufacturer. With the specified tire

inflation, the restraining cables shall be tightened to provide tire

deflection of 6 to 8 percent of the nominal tire-section width. After

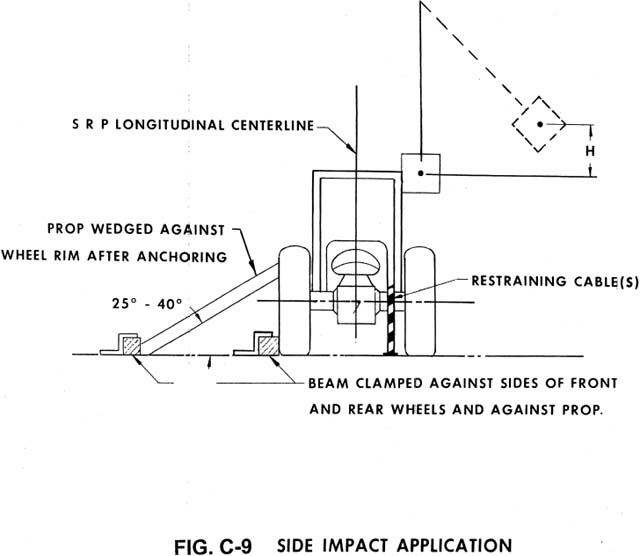

the vehicle is restrained properly, a wooden beam that is 6-in. x 6-in.

(150 mm x 150 mm) shall be driven tightly against the appropriate

wheels and clamped. For the test to the side, an additional wooden beam

shall be placed as a prop against the wheel nearest to the operator's

station, and shall be secured to the floor so that when it is

positioned against the wheel rim, it is at an angle of 25[deg] to

40[deg] to the horizontal. It shall have a length 20 to 25 times its

depth, and a width two to three times its depth (see Figures W-22 and

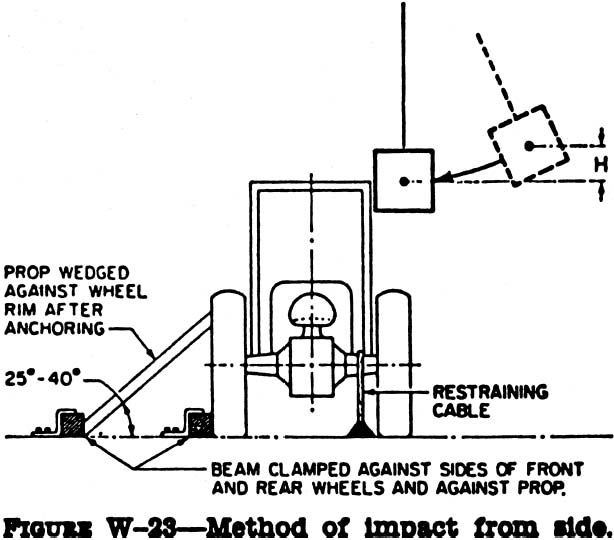

W-23).

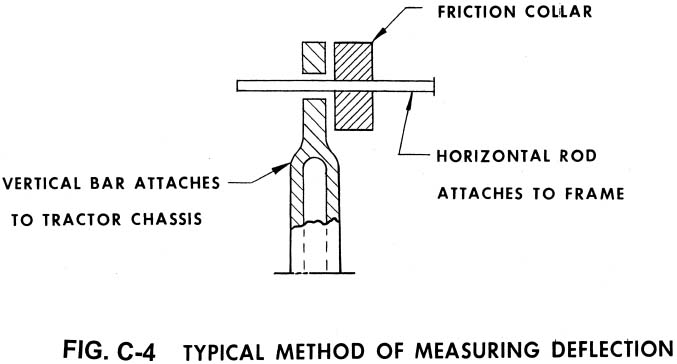

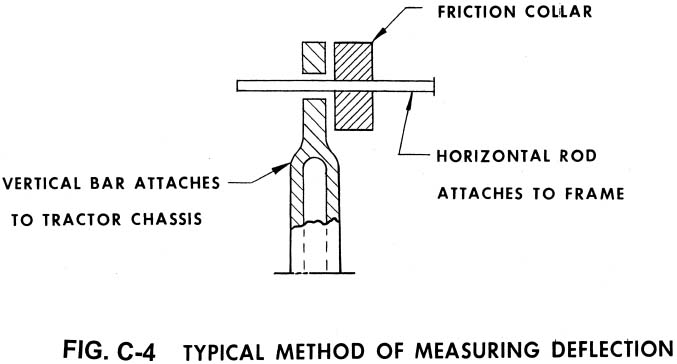

(v) Means shall be provided for indicating the maximum

instantaneous deflection along the line f impact. A simple friction

device is illustrated in Figure W-23.

(vi) No repair or adjustments may be carried out during the test.

(vii) When any cables, props, or blocking shift or break during the

test, the test shall be repeated.

(2) Test procedure. (i) General. The frame shall be evaluated by

imposing dynamic loading to the rear, followed by a load to the side on

the same frame. The pendulum dropped from the height (see the

definition of ``H'' in paragraph (j)(3) of this section) imposes the

dynamic load. The position of the pendulum shall be so selected that

the initial point of impact on the frame shall be in line with the arc

of travel of the center of gravity of the pendulum. A quick-release

mechanism should be used but, when used, it shall not influence the

attitude of the block.

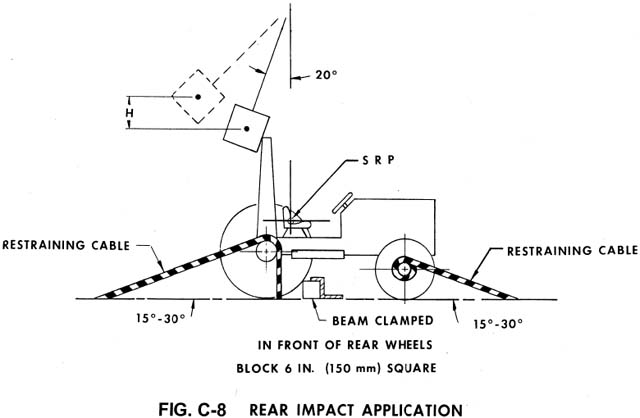

(ii) Impact at rear. The tractor shall be restrained properly

according to paragraphs (h)(1)(iii) and (h)(1)(iv) of this section. The

tractor shall be positioned with respect to the pivot point of the

pendulum so that the pendulum is 20[deg] from the vertical prior to

impact as shown in Figure W-22. The impact shall be applied to the

upper extremity of the frame at the point that is midway between the

centerline of the frame and the inside of the frame upright of a new

frame.

(iii) Impact at side. The blocking and restraining shall conform to

paragraphs (h)(1)(iii) and (h)(1)(iv) of this section. The center point

of impact shall be that structural member of the protective frame

likely to hit the ground first in a sideways accidental upset. The side

impact shall be applied to the side opposite that used for rear impact.

(i) Performance requirements. (1) General. (i) The frame, overhead

weather shield, fenders, or other parts in the operator area may be

deformed in these tests, but shall not shatter or leave sharp edges

exposed to the operator, or violate the dimensions shown in Figures W-

16 and W-17, and specified as follows:

D = 2 in. (51 mm) inside of the frame upright to the vertical

centerline of the seat;

E = 30 in. (762 mm);

F = Not less than 0 in. (0 mm) and not more than 12 in. (305 mm),

measured at the centerline of the seat backrest to the crossbar along

the line of load application as shown in Figure W-17; and

G = 24 in. (610 mm).

(ii) The material and design combination used in the protective

structure must be such that the structure can meet all prescribed

performance tests at 0 [deg]F (-18 [deg]C) according to 29 CFR

1926.1001(f)(2)(iv).

(2) Vehicle overturn performance requirements. The requirements of

this paragraph (i) must be met in both side and rear overturns.

(3) Static test performance requirements. Design factors shall be

incorporated in each design to withstand an overturn test as specified

by this paragraph (i). The structural requirements will be met

generally when FER is greater than 1.0 and FSB is greater than K-1 in

both side and rear loadings.

(4) Dynamic test performance requirements. Design factors shall be

incorporated in each design to withstand the overturn test specified by

this paragraph (i). The structural requirements will be met generally

when the dimensions in this paragraph (i) are used during both side and

rear loads.

(j) Definitions applicable to this section. (1) ``Agricultural

tractor'' means a wheel-type vehicle of more than 20 engine horsepower,

used in construction work, that is designed to furnish the power to

pull, propel, or drive implements. (SAE standard J333a-1970 (``Operator

protection for wheel-type agricultural and industrial tractors'')

defines ``agricultural tractor'' as a ``wheel-type vehicle of more than

20 engine horsepower designed to furnish the power to pull, carry,

propel, or drive implements that are designed for agricultural usage.''

Since this part 1926 applies only to construction work, the SAE

definition of ``agricultural tractor'' is adopted for purposes of this

subpart.)

(2) ``Industrial tractor'' means that class of wheel-type tractors

of more than 20 engine horsepower (other than rubber-tired loaders and

dozers described in 29 CFR 1926.1001), used in operations such as

landscaping, construction services, loading, digging, grounds keeping,

and highway maintenance.

(3) The following symbols, terms, and explanations apply to this

section:

E is = Energy input to be absorbed during side loading in

ft-lb (E'is in J [joules]);

E is = 723 + 0.4 W ft-lb (E' is = 100 + 0.12 W' ,

J);

E ir = Energy input to be absorbed during rear loading in

ft-lb (E' ir in J);

E ir = 0.47 W ft-lb (E' ir = 0.14 W', J);

W = Tractor weight as specified by 29 CFR 1926.1002(e)(1) and (e)(3),

in lb (W' , kg);

L = Static load, lb (kg);

D = Deflection under L, in. (mm);

L-D = Static load-deflection diagram;

Lm-Dm = Modified static load-deflection diagram

(Figure W-20). To account for an increase in strength due to an

increase in strain rate, raise L in the plastic range L x K;

K = Increase in yield strength induced by higher rate of loading (1.3

for hot, rolled, low-carbon steel 1010-1030). Low carbon is preferable;

however, when higher carbon or other material is used, K must be

determined in the laboratory. Refer to Norris, C.H., Hansen, R.J.,

Holley, M.J., Biggs, J.M., Namyet, S., and Minami, J.V., Structural

Design for Dynamic Loads, McGraw-Hill, New York, 1959, p. 3;

Lmax = Maximum observed static load;

Load Limit = Point on a continuous L-D curve at which the observed

static load is 0.8 Lmax (refer to Figure W-19);

Eu = Strain energy absorbed by the frame, ft-lb (J); area

under the Lm-Dm curve;

FER = Factor of energy ratio, FER = EuEis; also,

FER = EuEir;

Pb = Maximum observed force in mounting connection under a

static load, L, lb (kg);

Pu = Ultimate force capacity of mounting connection, lb

(kg);

FSB = Design margin for a mounting connection

(PuPb)-1; and

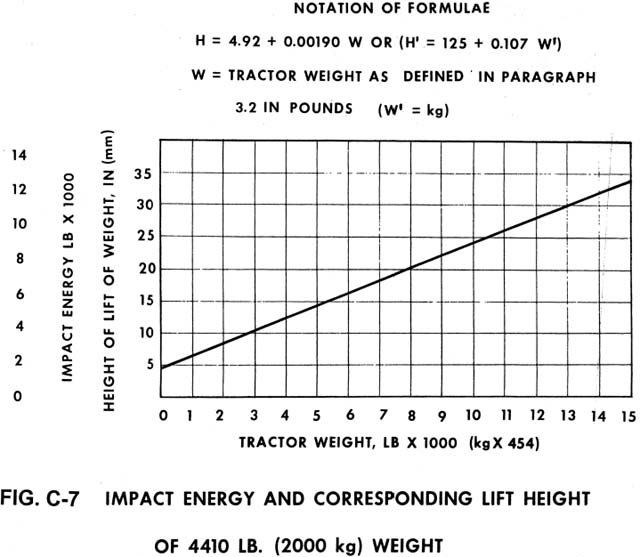

H = Vertical height of lift of 4,410-lb (2,000-kg) weight, in. (H',

mm). The weight shall be pulled back so that the height of its center

of gravity above the point of impact is defined as follows: H = 4.92 +

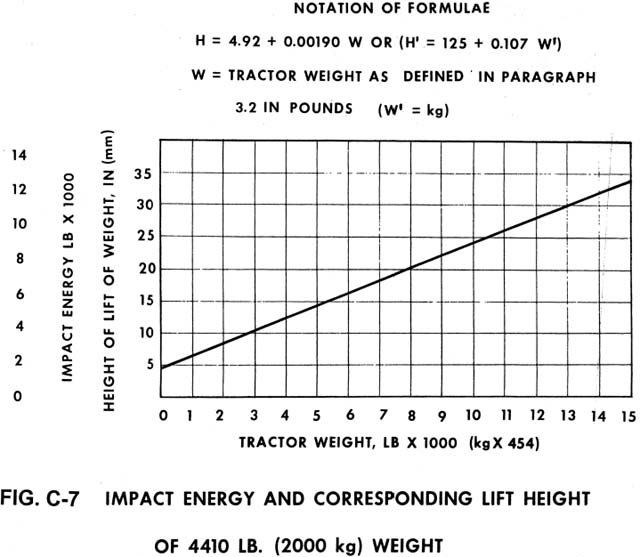

0.00190 W (H' = 125 + 0.107 W') (see Figure W-24).

(k) Source of standard. The standard in this section is derived

from, and restates, in part, Society of Automotive Engineers (``SAE'')

standard J334a-1970 (``Protective frame test procedures and performance

requirements''). The SAE standard appears in the 1971 SAE Handbook,

which may be examined at any OSHA regional office.

Sec. 1926.1003 Overhead protection for operators of agricultural and

industrial tractors used in construction.

(a) General. (1) Purpose. When overhead protection is provided on

wheel-type agricultural and industrial tractors, the overhead

protection shall be designed and installed according to the

requirements contained in this section. The provisions of 29 CFR

1926.1001 for rubber-tired dozers and rubber-tired loaders may be used

instead of the standards contained in this section. The purpose of this

standard is to minimize the possibility of operator injury resulting

from overhead hazards such as flying and falling objects, and at the

same time to minimize the possibility of operator injury from the cover

itself in the event of accidental upset.

(2) Applicability. This standard applies to wheel-type agricultural

and industrial tractors used in construction work (see 29 CFR

1926.1002(b) and (j)). In the case of machines to which 29 CFR 1926.604

(relating to site clearing) also applies, the overhead protection may

be either the type of protection provided in 29 CFR 1926.604, or the

type of protection provided by this section.

(b) Overhead protection. When overhead protection is installed on

wheel-type agricultural or industrial tractors used in construction

work, it shall meet the requirements of this paragraph. The overhead

protection may be constructed of a solid material. When grid or mesh is

used, the largest permissible opening shall be such that the maximum circle

that can be inscribed between the elements of the grid or mesh is 1.5 in.

(38 mm) in diameter. The overhead protection shall not be installed in such

a way as to become a hazard in the case of upset.

(c) Test procedures--general. (1) The requirements of 29 CFR

1926.1002(d), (e), and (f) shall be met.

(2) Static and dynamic rear load application shall be distributed

uniformly along a maximum projected dimension of 27 in. (686 mm), and a

maximum area of 160 sq. in. (1,032 sq. cm), normal to the direction of

load application. The load shall be applied to the upper extremity of

the frame at the point that is midway between the centerline of the

seat and the inside of the frame upright.

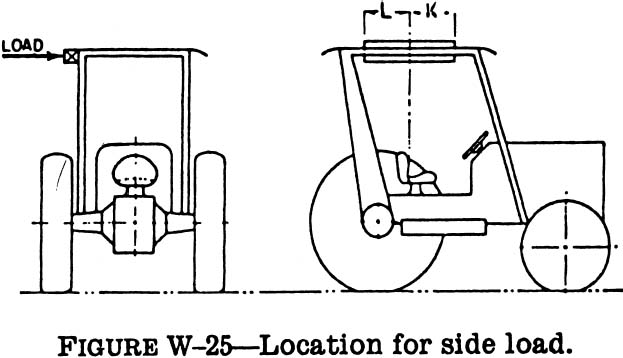

(3) The static and dynamic side load application shall be

distributed uniformly along a maximum projected dimension of 27 in.

(686 mm), and a maximum area of 160 sq. in. (1,032 sq. cm), normal to

the direction of load application. The direction of load application is

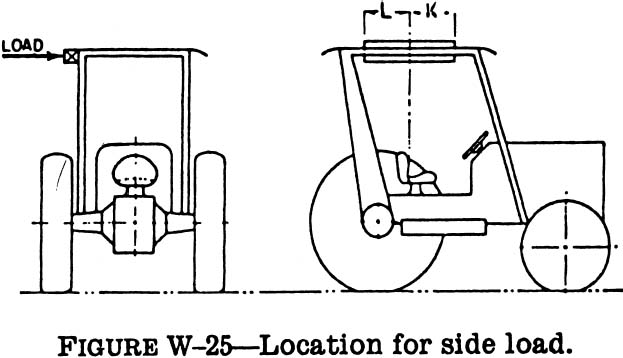

the same as in 29 CFR 1926.1002 (g) and (h). To simulate the

characteristics of the structure during an upset, the center of load

application may be located from a point 24 in. (610 mm) (K) forward to

12 in. (305 mm) (L) rearward of the front of the seat backrest, to best

use the structural strength (see Figure W-25).

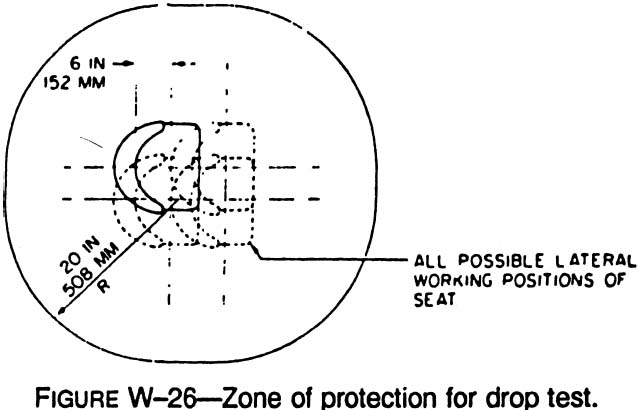

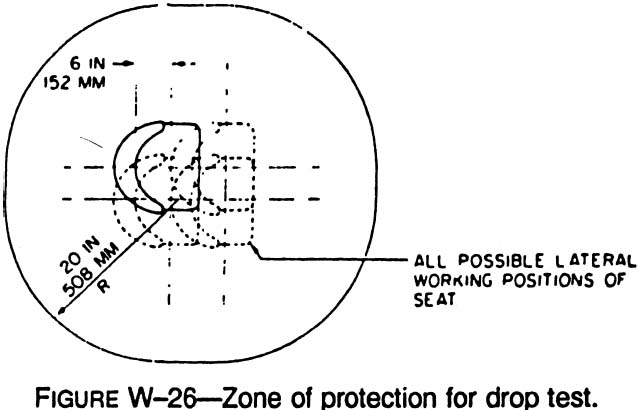

(d) Drop test procedures. (1) The same frame shall be subjected to

the drop test following either the static or dynamic test.

(2) A solid steel sphere or material of equivalent spherical

dimension weighing 100 lb (45.4 kg) shall be dropped once from a height

10 ft (3.08 m) above the overhead cover.

(3) The point of impact shall be on the overhead cover at a point

within the zone of protection as shown in Figure W-26, which is

furthest removed from major structural members.

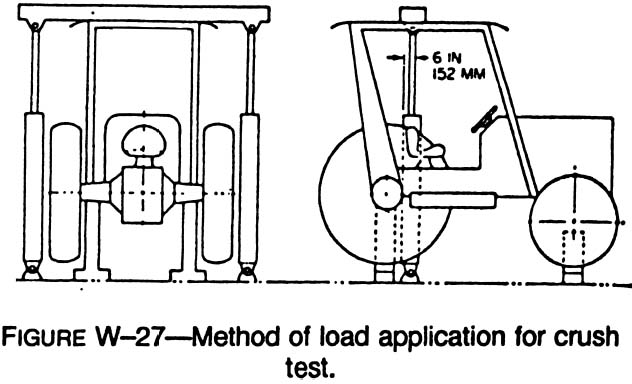

(e) Crush test procedure. (1) The same frame shall be subjected to

the crush test following the drop test and static or dynamic test.

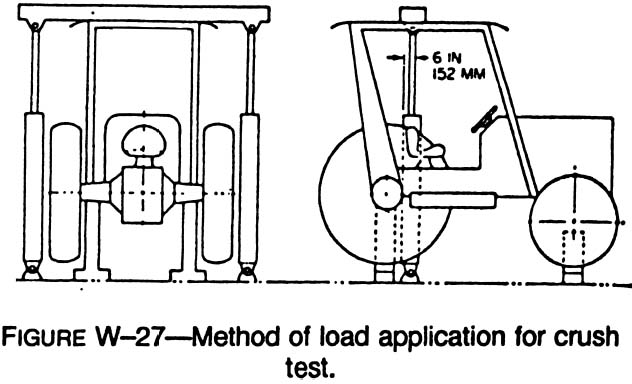

(2) The test load shall be applied as shown in Figure W-27, with

the seat positioned as specified in 29 CFR 1926.1002(d)(4). Loading

cylinders shall be mounted pivotally at both ends. Loads applied by

each cylinder shall be equal within two percent, and the sum of the

loads of the two cylinders shall be two times the tractor weight as set

forth in 29 CFR 1926.1002(e)(1). The maximum width of the beam

illustrated in Figure W-27 shall be 6 in. (152 mm).

(f) Performance requirements. (1) General. The performance

requirements set forth in 29 CFR 1926.1002(i)(2), (3), and (4) shall be

met.

(2) Drop test performance requirements. (i) Instantaneous

deformation due to impact of the sphere shall not enter the protected

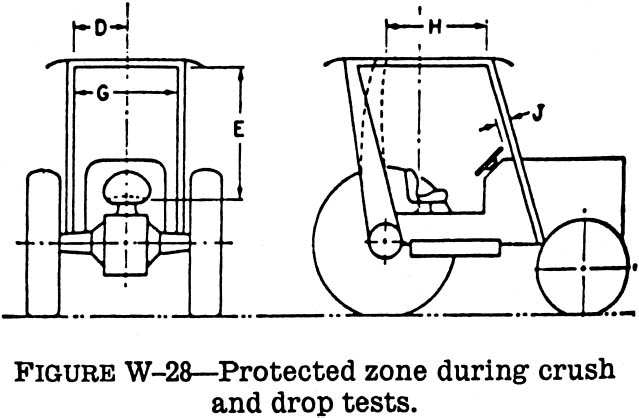

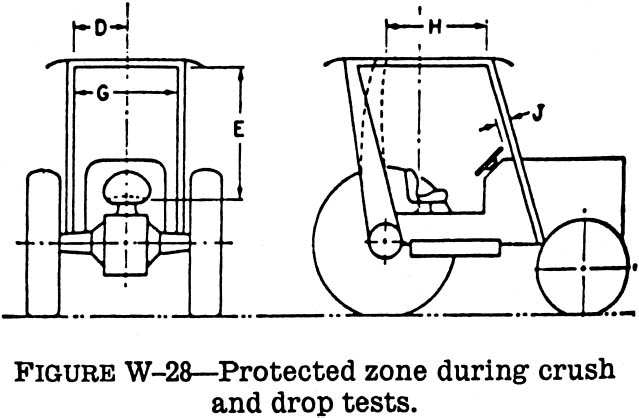

zone as illustrated in Figures W-25, W-26, and W-28.

(ii) In addition to the dimensions set forth in 29 CFR

1926.1002(i)(1)(i), the following dimensions apply to Figure W-28:

H = 17.5 in. (444 mm); and

J = 2 in. (50.8 mm), measured from the outer periphery of the steering

wheel.

(3) Crush test performance requirements. The protected zone as

described in Figure W-28 must not be violated.

(g) Source of standard. This standard is derived from, and

restates, in part, the portions of Society of Automotive Engineers

(``SAE'') standard J167-1970 (``Protective frame with overhead

protection--test procedures and performance requirements''), which

pertain to overhead protection requirements. The SAE standard appears

in the 1971 SAE Handbook, which may be examined at any OSHA regional

office.

Appendix A to Subpart W--Figures W-14 through W-28

BILLING CODE 4510-26-P

PART 1928--[AMENDED]

Subpart C--[Amended]

0

3. Revise the authority citation to part 1928 to read as follows:

Authority: Sections 4, 6, and 8 of the Occupational Safety and

Health Act of 1970 (29 U.S.C. 653, 655, 657); and Secretary of

Labor's Order No. 12-71 (36 FR 8754), 8-76 (41 FR 25059), 9-83 (48

FR 35736), 1-90 (55 FR 9033), 6-96 (62 FR 111), 3-2000 (65 FR 50017)

or 5-2002 (67 FR 65008) as applicable; and 29 CFR part 1911.

Section 1928.21 also issued under section 29, Hazardous

Materials Transportation Uniform Safety Act of 1990 (Pub. L. 101-

615, 104 Stat. 3244 (49 U.S.C. 1801-1819 and 5 U.S.C. 553)).

0

4. Revise paragraph (b)(1) of Sec. 1928.51 to read as follows:

Sec. 1928.51 Roll-over protective structures (ROPS) for tractors used

in agricultural operations.

* * * * *

(b) * * *

(1) Roll-over protective structures (ROPS). ROPS shall be provided

by the employer for each tractor operated by an employee. Except as

provided in paragraph (b)(5) of this section, a ROPS used on wheel-type

tractors shall meet the test and performance requirements of 29 CFR

1928.52, 1928.53, or 1926.1002 as appropriate. A ROPS used on track-

type tractors shall meet the test and performance requirements of 29

CFR 1926.1001.

* * * * *

0

5. Add Sec. Sec. 1928.52, 1928.53, and a new Appendix B to subpart C

to read as follows:

Sec. 1928.52 Protective frames for wheel-type agricultural tractors--

test procedures and performance requirements.

(a) Purpose. The purpose of this section is to establish the test

and performance requirements for a protective frame designed for wheel-

type agricultural tractors to minimize the frequency and severity of

operator injury resulting from accidental upsets. General requirements

for the protection of operators are specified in 29 CFR 1928.51.

(b) Types of tests. All protective frames for wheel-type

agricultural tractors shall be of a model that has been tested as

follows:

(1) Laboratory test. A laboratory energy-absorption test, either

static or dynamic, under repeatable and controlled loading, to permit

analysis of the protective frame for compliance with the performance

requirements of this standard.

(2) Field-upset test. A field-upset test under controlled

conditions, both to the side and rear, to verify the effectiveness of

the protective system under actual dynamic conditions. Such testing may

be omitted when:

(i) The analysis of the protective-frame static-energy absorption

test results indicates that both FERis and FERir

(as defined in paragraph (d)(2)(ii) of this section) exceed 1.15; or

(ii) The analysis of the protective-frame dynamic-energy absorption

test results indicates that the frame can withstand an impact of 15

percent greater than the impact it is required to withstand for the

tractor weight as shown in Figure C-7.

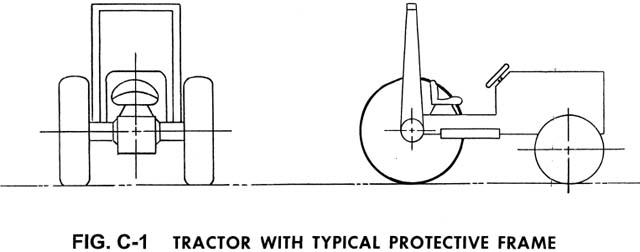

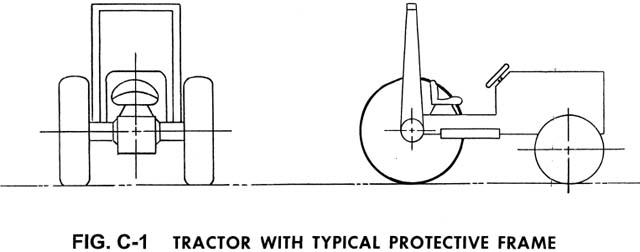

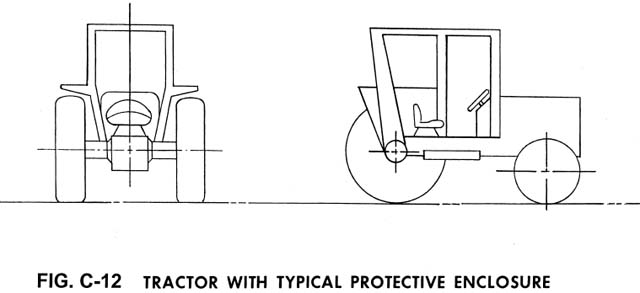

(c) Descriptions. (1) Protective frame. A protective frame is a

structure comprised of uprights mounted to the tractor, extending above

the operator's seat. A typical two-post frame is shown in Figure C-1.

(2) Overhead weather shield. When an overhead weather shield is

available for attachment to the protective frame, it may be in place

during tests provided it does not contribute to the strength of the

protective frame.

(3) Overhead falling object protection. When an overhead falling-

object protection device is available for attachment to the protective

frame, it may be in place during tests provided it does not contribute

to the strength of the protective frame.

(d) Test procedures. (1) General. (i) The tractor weight used shall

be that of the heaviest tractor model on which the protective frame is

to be used.

(ii) Each test required under this section shall be performed on a

new protective frame. Mounting connections of the same design shall be

used during each such test.

(iii) Instantaneous deflection shall be measured and recorded for

each segment of the test; see paragraph (e)(1)(i) of this section for

permissible deflections.

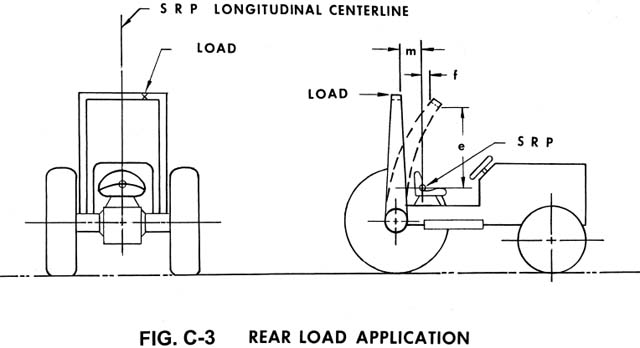

(iv) The seat-reference point (``SRP'') in Figure C-3 is that point

where the vertical line that is tangent to the most forward point at

the longitudinal seat centerline of the seat back, and the horizontal

line that is tangent to the highest point of the seat cushion,

intersect in the longitudinal seat section. The seat-reference point

shall be determined with the seat unloaded and adjusted to the highest

and most rearward position provided for seated operation of the

tractor.

(v) When the centerline of the seat is off the longitudinal center,

the frame loading shall be on the side with the least space between the

centerline of seat and the protective frame.

(vi) Low-temperature characteristics of the protective frame or its

material shall be demonstrated as specified in paragraph (e)(1)(ii) of

this section.

(vii) Rear input energy tests (static, dynamic, or field-upset)

need not be performed on frames mounted to tractors having four driven

wheels and more than one-half their unballasted weight on the front

wheels.

(viii) Accuracy table:

------------------------------------------------------------------------

Measurements Accuracy

------------------------------------------------------------------------

Deflection of the frame, in. (mm).. 5 percent of the

deflection measured.

Vertical weight, lb (kg)........... 5 percent of the weight

measured.

Force applied to the frame, pounds 5 percent of the force

force (newtons). measured.

Dimensions of the critical zone, 0.5 in. (12.5 mm).

in. (mm).

------------------------------------------------------------------------

(2) Static test procedure. (i) The following test conditions shall

be met:

(A) The laboratory mounting base shall be the tractor chassis for

which the protective frame is designed, or its equivalent;

(B) The protective frame shall be instrumented with the necessary

equipment to obtain the required load-deflection data at the locations

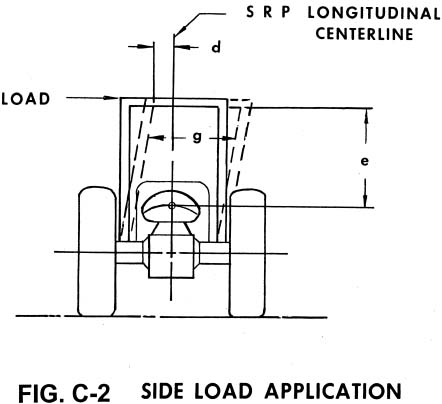

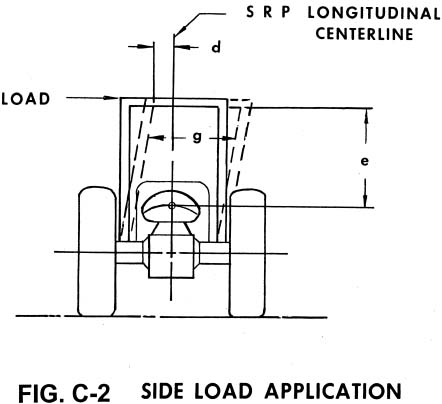

and directions specified in Figures C-2 and C-3; and

(C) When the protective frame is of a one- or two-upright design,

mounting connections shall be instrumented with the necessary equipment

to record the required force to be used in paragraph (d)(2)(iii)(E) and

(J) of this section. Instrumentation shall be placed on mounting

connections before installation load is applied.

(ii) The following definitions shall apply:

W = Tractor weight (see 29 CFR 1928.51(a)) in lb (W' in kg);

Eis = Energy input to be absorbed during side loading in ft-lb (E'is in

J [joules]);

Eis = 723 + 0.4 W (E'is = 100 + 0.12 W');

Eir = Energy input to be absorbed during rear loading in ft-lb (E'ir in

J);

Eir = 0.47 W (E'ir = 0.14 W');

L = Static load, lbf [pounds force], (N) [newtons];

D = Deflection under L, in. (mm);

L-D = Static load-deflection diagram;

Lmax = Maximum observed static load;

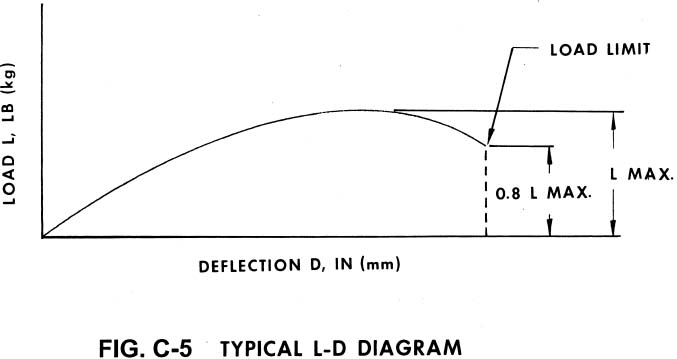

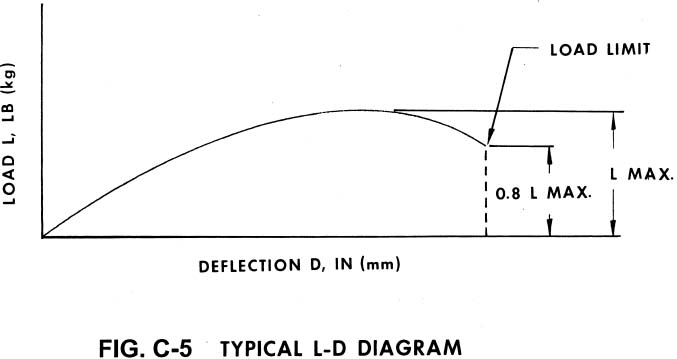

Load Limit = Point on a continuous L-D curve where the observed static

load is 0.8 Lmax on the down slope of the curve (see Figure C-5);

Eu = Strain energy absorbed by the frame in ft-lb (J); area under the

L-D curve;

FER = Factor of energy ratio;

FERis = EuEis;

FERir = EuEir;

Pb = Maximum observed force in mounting connection under a static load,

L lbf (N);

Pu = Ultimate force capacity of a mounting connection, lbf (N);

FSB = Design margin for a mounting connection; and

FSB = Pu/Pb

(iii) The test procedures shall be as follows:

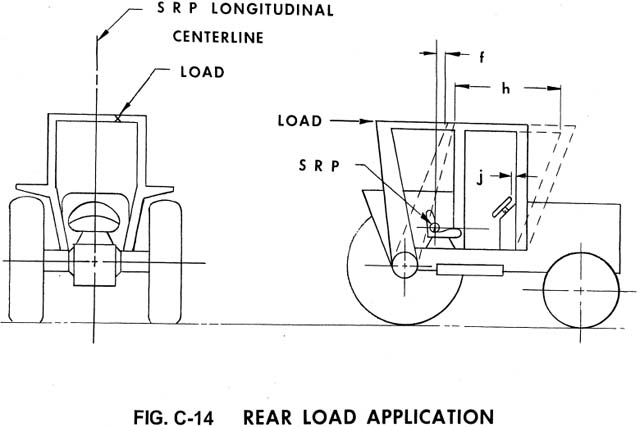

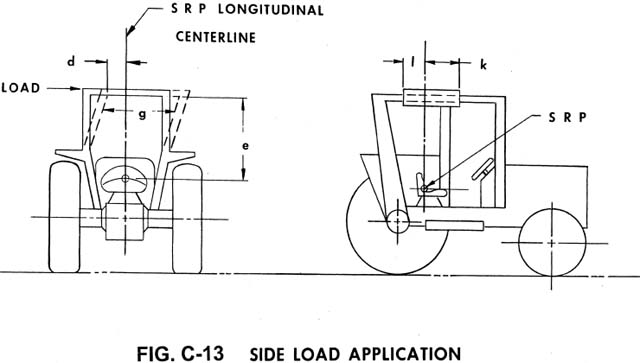

(A) Apply the rear load according to Figure C-3, and record L and D

simultaneously. Rear-load application shall be distributed uniformly on

the frame over an area perpendicular to the direction of load

application, no greater than 160 sq. in. (1,032 sq. cm) in size, with

the largest dimension no greater than 27 in. (686 mm). The load shall

be applied to the upper extremity of the frame at the point that is

midway between the center of the frame and the inside of the frame upright.

When no structural cross member exists at the rear of the frame, a substitute

test beam that does not add strength to the frame may be used to complete

this test procedure. The test shall be stopped when:

(1) The strain energy absorbed by the frame is equal to or greater

than the required input energy Eir; or

(2) Deflection of the frame exceeds the allowable deflection (see

paragraph (e)(1)(i) of this section); or

(3) Frame load limit occurs before the allowable deflection is

reached in rear load (see Figure C-5).

(B) Using data obtained under paragraph (d)(2)(iii)(A) of this

section, construct the L-D diagram shown in Figure C-5;

(C) Calculate Eir;

(D) Calculate FERir;

(E) Calculate FSB as required by paragraph (d)(2)(i)(C) of this

section;

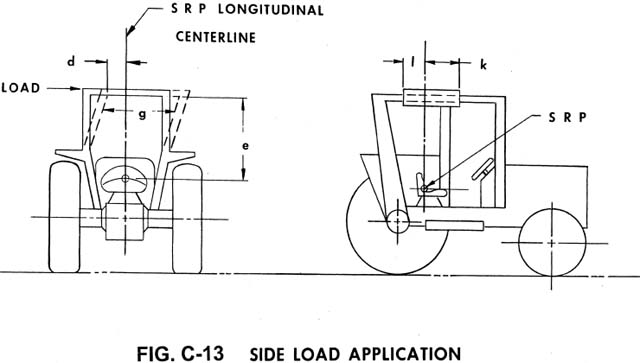

(F) Apply the side-load tests on the same frame, and record L and D

simultaneously. Side-load application shall be at the upper extremity

of the frame at a 90[deg] angle to the centerline of the vehicle. The

side load shall be applied to the longitudinal side farthest from the

point of rear-load application. Apply side load L as shown in Figure C-

2. The test shall be stopped when:

(1) The strain energy absorbed by the frame is equal to or greater

than the required input energy Eis; or

(2) Deflection of the frame exceeds the allowable deflection (see

paragraph (e)(1)(i) of this section); or

(3) Frame load limit occurs before the allowable deflection is

reached in side load (see Figure C-5).