- Standard Number:

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed. Note that our enforcement guidance may be affected by changes to OSHA rules. Also, from time to time we update our guidance in response to new information. To keep apprised of such developments, you can consult OSHA's website at https://www.osha.gov.

April 24, 1996

Mr. Verne R. Brown

c/o ENMET Corporation

P.O. Box 979

Ann Arbor, MI 48106-0979

Dear Mr. Brown:

This is in response to your letter of December 12, 1995, in which you requested a clarification of 29 CFR 1910.146, the Occupational Safety and Health Administration's (OSHA's) Permit-required Confined Spaces (PRCS) standard. Specifically, your request focuses on whether a down-stream blower, ventilating the workplace by negative pressure, is permitted for sewer manhole entries under the alternate entry procedures of paragraph (c)(5) of the standard. Please accept our apology for the delay in this response.

The Agency's position is that the required continuous forced air ventilation specified in paragraph (c)(5)(i)(B) means a delivery system or device that provides positive pressure for the space where the employees are working. A negative pressure application as indicated in the sketch provided is not acceptable.

In response to your closing comments about the alternate entry procedures, there can be substantial employer benefits in applying the alternate entry procedures of (c)(5). However, to obtain these benefits, all the aspects of paragraph (c)(5) must be complied with to assure an employees safety. The demonstration burdens of (c)(5)(i)(A) and (c)(5)(i)(B), from a compliance perspective, are significant.

The first required demonstration by the employer is that the only hazards posed by the space are actual or potential atmospheric hazards. This means that the space must not have the potential for engulfment or any other serious safety or health hazard.

The second required demonstration is documentation that the forced air ventilation being used is sufficient to maintain the space "safe for entry." In the preamble discussion of (c)(5)(i)(B), OSHA provided guidance to the regulated community as to the concentration level (up to 50% of the level that would constitute a hazardous atmosphere considered "safe for entry"). Appendix D (pages D-4 and D-5) of the compliance directive "OSHA Instruction CPL 2.100" discusses the employer's demonstration burden to ensure that a space is "safe for entry."

If you have further questions on this response please contact [the Office of General Industry Compliance Assistance at (202) 693-1850].

Sincerely,

John B. Miles, Jr., Director

Directorate of Compliance Programs

December 12, 1995

H. Berrien Zettler

Deputy Director

Directorate of Compliance Programs

Occupational Health and

Safety Administration

200 Constitution Avenue

Washington, DC 20210

Dear Mr. Zettler,

The purpose of this communication is to request a clarification by OSHA as to the appropriate ventilation methodology which should be implemented when an employer elects to use the "Alternate Procedure" included in sections (c)(5)(i) and (c)(5)(ii) of CFR 1910.146, the Permit-Required Confined Spaces safety standard.

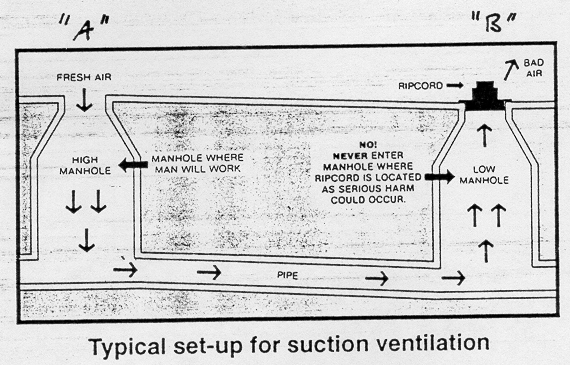

At a recent forum on Confined Space entry practices, significantly divergent opinions were presented on the ventilation methodology to be followed in order to comply with the above referenced standard. The conflict is best discussed by the diagram below which has been excerpted from an application guide by a maker of exhaust (i.e. "suction") blowers for sewer manhole use. (The designation of sewer manhole "A", and sewer manhole "B" have been added to clarify the question to be resolved.)

An attendee vigorously maintained that the operation of an exhaust ("suction") blower snugly inserted in the manhole opening "B" constituted CFR 1910.146(c)(5)(ii) ventilation requirements for the entrant performing tasks in manhole "A". The individual offered no technical discussion of blower capacity, distance between "A" and "B", diameter of the main sewer pipe, nor of additional sewer laterals which might emanate from manholes "A" or "B". Furthermore, the sewer system in their scenario is open and continuous - it has not been blocked or plugged in any way!!

The opposing opinions held that exhaust ventilation performed in the manner shown in above diagram did not comply with the spirit or the literal requirements of the "Alternate Procedure" for the reasons listed below:

1. The preamble to CFR 1910.146 clearly ascribes the justification for the inclusion in the standard of the "Alternate Procedure" to the telecommunication industry practice of continuously venting below ground vaults with a forced air blower. A review of ventilation policies and practices of that industry clearly shows the use of a positive pressure (forced air) ventilation blower which directs the cleanest available outside air through flexible ribbed hoses to the work area of the entrant (usually in the lower region of the telecommunication vault). Exhaust or suction ventilation is not the common practice of the telecommunication industry.

2. Section (c)(5)(ii)(E) requires "continuous forced air ventilation" for compliance with the "Alternate Procedure." The phrase "forced air ventilation" is synonymous with "positive pressure" blowers but did not appear to the opposing view to condone vacuum or "suction" ventilation (which is, of course, "negative pressure").

3. Section (c)(5)(ii)(E)(2) requires the "forced air ventilation"... to be "so directed as to ventilate the immediate area where an employed is in the space." It is well-known from ventilation principles that vacuum or negative pressure can not "direct" air movement. By contrast, "forced air" (positive pressure) may be directed a distance up to 30 times the diameter of the air delivery hose.

4. Section (c)(5)(ii)(E)(3) requires that the "forced air ventilation" be "from a clean source and may not increase the hazards in the space." Since the scenario under discussion is a continuous unplugged live sewer system, the opposing view held that vacuum, (exhaust or negative pressure) was potentially dangerous in a sewer system since some contaminants (not "clean" air) could also be drawn into the lower levels of manhole "A" where the entrant is located.

To summarize, the question asked of OSHA is simply: When unattended sewer entry work proceeds in compliance with the "Alternate Procedure" of CFR 1910.146, can there be an exhaust (suction) ventilator in a connected (but unoccupied) manhole "B", or must there be a positive pressure (forced air) blower located immediately outside the permit space "A" blowing clean air through a hose to the immediate work area of the entrant inside space "A"?

Clearly, many thousands of American workers in both the public and private sector enter and perform tasks in sanitary sewer manholes each day. These spaces could present life-threatening atmospheric hazards if the "Alternate Procedure" ventilation methodology is improper or inadequate. A prompt response to the issues raised in this letter is respectfully requested for the benefit of employers, employees, state and federal compliance officers and the health and safety professional community in general.

In closing it should be noted that many safety conscious American employers have duly noted the more expedient and cost effective aspects of the "Alternate Procedure" section of the standard - fewer people, less equipment, shorter time, thus lower cost as compared to full-permit entry. In addition, these employers, may also have noted that Appendix "C" (Example #1A) gives OSHA endorsement to sewer manhole entry without permit and without attendant provided such "Alternate Procedure" requirements as air testing performed "pre-entry and periodically thereafter", continuous "mechanical ventilation" and "certification" of safe conditions by the entry supervisor are performed. A clarification from OSHA of proper ventilation methodology in sewer environments to be entered under the "Alternate Procedure" is, in my opinion, urgently needed by all parties.

Respectfully Submitted,

Verne R. Brown, PhD

Chairman, Michigan Department of Labor

Confined Space Advisory

Committee Member, AIHA

Confined Space Committee Advisor, State of Michigan

Construction Safety Standard Commission