- Standard Number:

OSHA requirements are set by statute, standards and regulations. Our interpretation letters explain these requirements and how they apply to particular circumstances, but they cannot create additional employer obligations. This letter constitutes OSHA's interpretation of the requirements discussed. Note that our enforcement guidance may be affected by changes to OSHA rules. Also, from time to time we update our guidance in response to new information. To keep apprised of such developments, you can consult OSHA's website at https://www.osha.gov.

March 11, 2004

Mr. Mike Mathisen

Plant QA Manager

Central Western Fabricators, Inc.

400 West Second Street

Atlantic, Iowa 50022-1001

Re: Part 1926 Subpart R, §1926.754(c)(1); shop-installed shear connectors; shop-installed pour-stop angles

Dear Mr. Mathisen:

This is in response to your fax dated December 4, 2003, to the Occupational Safety and Health Administration (OSHA) in which you ask about a fabricator's responsibility for compliance with OSHA requirements if it follows design instructions, from the erector or engineer of record, that do not conform to 29 CFR 1926.754(c). You also ask whether pour-stop angles are covered by §1926.754(c)(1) and thus prohibited from being shop-installed. We apologize for the delay in responding.

We have paraphrased your questions as follows:

Question (1a): Scenario: A steel erector requests that a steel fabricator [shop-installed shear connectors be attached] to the top flange of steel beams, joists and beam attachments. Can the steel fabricator be cited for a violation of 29 CFR 1926.754(c)(1)(i) if it follows this request?

Answer

Title 29 CFR 1926.754(c)(1)(i) "Walking/working surfaces" states:

Tripping hazards. Shear connectors (such as headed steel studs, steel bars or steel lugs), reinforcing bars, deformed anchors or threaded studs shall not be attached to the top flanges of beams, joists or beam attachments so that they project vertically from or horizontally across the top flange of the member until after the metal decking, or other walking/working surface, has been installed.

Shear connectors are prohibited from being installed prior to the decking where they project either vertically from the top flange of the beam, or horizontally across the top flange of the beam. As explained in the preamble of the final rule "when attachments, like shear connectors, are shop-welded to the top flange of beams, the resulting projections can create a significant tripping hazard."1 These pose a tripping hazard because, during the steel erection process, the top flanges of the beams serve as a walking surface.

In OSHA Directive CPL 2-134 ("Inspection policy and procedures for OSHA's steel erection standards for construction"), we included the following Question and Answer:

Question 25: I have beams with shop-installed shear connectors at 20 feet. If the employer requires the use of fall protection for all workers, including connectors and deckers, would the presence of the shop-installed shear connectors on these beams still be a violation under §1926.754(c)(1)?

Answer: No. If an employer requires that all workers, including those engaged in connecting and in decking (as well as deckers in a CDZ), be protected from falls by conventional fall protection, then the failure to meet the requirements of §1926.754(c)(1) would be considered de minimis, and no citation would be issued.

Therefore, erecting a steel beam (joist or beam attachment) with shop installed connectors is prohibited unless all exposed workers are protected by fall protection. You ask whether a fabricator is subject to an OSHA citation for shop-installing shear connectors. Title 29 CFR 1926.750 of the steel erection standard states:

This document was edited on 01/12/2010 to strike information that no longer reflects current OSHA policy.

(a) This subpart sets forth requirements to protect employees from the hazards associated with steel erection activities involved in the construction, alteration, and/or repair of single and multi-story buildings, bridges, and other structures where steel erection occurs. The requirements of this subpart apply to employers engaged in steel erection unless otherwise specified.... [Emphasis added.]

* * *

(b)(1) Steel erection activities include hoisting, laying out, placing, connecting, welding, burning, guying, bracing, bolting, plumbing and rigging structural steel, steel joists and metal buildings; installing metal decking, curtain walls, window walls, siding systems, miscellaneous metals, ornamental iron and similar materials; and moving point-to-point while performing these activities.

Subpart R thus applies only to those engaged in steel erection activities. Steel fabrication by itself is not considered a "steel erection activity" under §1926.750(a) or (b). Therefore, for purposes of this standard, unless a fabricator is erecting the beams it has welded the shear connectors to, or performing some other activity covered by the standard, it is not engaged in steel erection activities and therefore would not be subject to a citation for violating §1926.754(c)(1).

However, we must caution you that although the fabricator is not subject to an OSHA citation under §1926.754(c)(1) for shop-installing shear connectors, whoever is the current erector (or a replacement erector) is required under the standard to refuse to erect beams that have shop-installed shear connectors unless all exposed workers, including those engaged in connecting and in decking (as well as deckers in a CDZ), are protected by conventional fall protection in accordance with the directive. In your scenario, the original erector requests the shear connectors to be shop-installed. As long as that erector is willing to comply with the 100-percent fall protection policy described in the directive, it is permitted to erect those beams. But if that erector were to be replaced, a subsequent erector would be similarly prohibited from erecting such beams unless it too were willing to comply with the 100-percent fall protection policy.

This document was edited on 01/12/2010 to strike information that no longer reflects current OSHA policy.

The issues of the steel fabricator's potential contract or tort liability, should the steel erector refuse to erect the beams, erect them but not enforce 100-percent fall protection, or in the event that an accident were to occur as a result of the use of beams with shop-installed shear connectors, are legal questions that are beyond the purview of this office to answer.

Question (1b): The engineer of record requests that a steel fabricator shop install sheer connector to the top flange of steel beams, joists and beam attachments. Will the steel fabricator be cited for an OSHA violation if it follows this request?

Answer

As explained above, a steel fabricator would not be cited under §1926.754(c)(1) unless it was engaged in a steel erection activity. However, in many instances the engineer of record is not affiliated with the steel erector. While the engineer may request shear connectors to be shop-installed, the erector would be prohibited from erecting those beams unless it was willing to comply with 100-percent fall protection as detailed in the directive.

As discussed above, it is outside this office's purview to comment on contractual, tort or other legal liability issues.

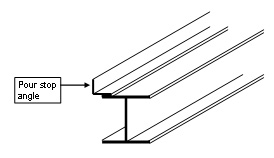

Question (2): Does §1926.754(c)(1) also prohibit the shop welding of a pour-stop angle on the top flange of a beam as shown in the illustration below?

Answer

Yes; we addressed this issue in our December 24, 2003, letter to Mr. Ward. Section 1926.754(c)(1)(i) applies to "shear connectors and other similar devices." [Emphasis added.] Read as whole, the focus of the standard is on tripping hazards associated with field-installed attachments.2 The welding of the base of the pour-stop angle to the top flange effectively extends the width of that flange and becomes part of the walking surface. Since the upturned angle rises vertically from the (extended) flange, the tripping hazard addressed by §1926.754(c)(1)(i) is created and the shop attachment of the pour-stop angle to the beam would violate the provision. However, as explained in Question 1(a) above, this violation would be considered de minimis if 100-percent fall protection is used in accordance with Question and Answer 25 in the steel erection directive.3

If you need additional information, please contact us by fax at: U.S. Department of Labor, OSHA, Directorate of Construction, Office of Construction Standards and Guidance, fax # 202-693-1689. You can also contact us by mail at the above office, Room N3468, 200 Constitution Avenue, N.W., Washington, D.C. 20210, although there will be a delay in our receiving correspondence by mail.

Sincerely,

Russell B. Swanson, Director

Directorate of Construction

1 See 66: Federal Register, page 5213, January 18, 2001. [ back to text ]

2 As stated in the Preamble to the Final Rule for Safety Standards for Steel Erection at 66 Fed. Reg. 5213 (January 18, 2001): "Paragraph (c) of the final rule sets forth requirements that address slipping/tripping hazards encountered when working on steel structures. * * * when attachments * * * are shop-welded to the top flange of beams* * *. Field installations of these attachments can significantly reduce exposure to this hazard." [ back to text ]

3 Note that this directive will be updated in the upcoming months. All Questions and Answers from the original version will be carried over into the revised directive, but will have new numbers. [ back to text ]