- Part Number:1910

- Part Number Title:Occupational Safety and Health Standards

- Subpart:1910 Subpart Z

- Subpart Title:Toxic and Hazardous Substances

- Standard Number:

- Title:Questions and Answers - Methylene Chloride Control in Furniture Stripping

- GPO Source:

Appendix C to Section 1910.1052 - Questions and Answers - Methylene Chloride Control in Furniture Stripping

CDC - Center for Disease Control and Prevention and NIOSH - Questions and Answers - Methylene Chloride Control in Furniture Stripping. U.S. Department of Health and Human Services Public Health Service Centers for Disease Control and Prevention National Institute for Occupational Safety and Health. September 1993

Disclaimer. Mention of any company or product does not constitute endorsement by the Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health. This document is in the public domain and my be freely copied or reprinted. Copies of this and other NIOSH documents are available from: Publications dissemination, DSDTT, National Institute for Occupational Safety and Health, 4676 Columbia Parkway, Cincinnati, OH 45226. Fax (513)533-8573. For information about other occupational safety and health problems, call 1-800-35-NIOSH. DHHS (NIOSH) Publication No. 93-133

Includes a diagram of a Slot Hood with the caption: Figure 1 - Slot Hood. Text: Introduction: This Pamphlet answers commonly asked questions about the hazards from exposure to methylene chloride. It also describes approaches to controlling methylene cloride exposure during the most common furniture stripping processes. Although these approaches were developed and field tested by NIOSH, each setting requires custom installation because of the different air flow interferences at each site. What is the Stripping Solution Base? The most common active ingredient in paint removers is a chemical called methylene chloride. Methylene chloride is present in the paint remover to penetrate, blister, and finally lift the old finish. Other chemicals in paint removers work to accelerate the stripping process, to retard evaporation, and to act as thickening agents. These other ingredients may include: methanol, toulene, acetone, or paraffin.1 Is Methylene Chloride Bad for Me? Exposure to methylene chloride may cause short-term health effects or long-term health effects. Short-Term (acute) Health Effects: Exposure to high levels of paint removers over short periods of time can cause irritation to the skin, eyes, mucous membranes, and respiratory tract. Other symptoms of high exposure are dizziness, headache, and lack of coordination. The occurrence of any of these symptoms indicates that you are being exposed to high levels of the methylene chloride. at the onset of any of these symptoms, you should leave the work area, get some fresh air, and determine why the levels were high. A portion of inhaled methylene chloride is converted by the body to carbon monoxide. which can lower the blood's abili1y to carry oxygen. When the solvent is used properly, however. the levels of carbon monoxide should not be hazardous. Individuals with cardiovascular or pulmonary health problems should check with their physician before using the paint stripper. Individuals experiencing severe symptoms such as shortness of breath or chest pains should obtain proper medical care immediately.2 Long-term (Chronic) Health Effects: Methylene chloride has been shown to cause cancer in certain laboratory animal tests. The available human studies do not provide the necessary information to determine whether methylene chloride causes cancer in humans. However, as a result of the animal studies, methylene chloride is

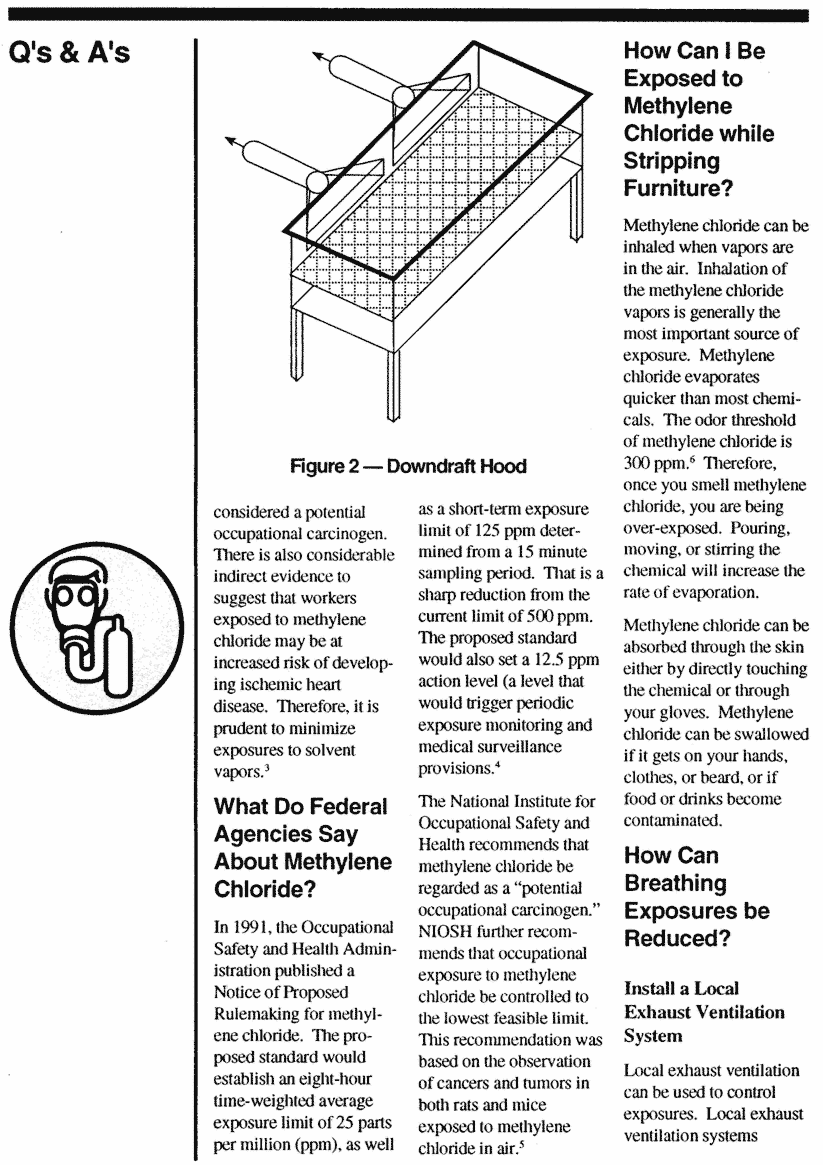

Includes a diagram of a downdraft hood with the caption: Figure 2 - Downdraft hood. Text: considered a potential occupational carcinogen. There is also considerable indirect evidence to suggest that workers exposed to methylene chloride may be at increased risk of developing ischemic heart disease. Therefore, it is prudent to minimize exposures to solvent vapors.3 What Do Federal Agencies Say About Methylene Chloride? In 1991, the Occupational Safety and Health Administration published a Notice of Proposed Rulemaking for methylene chloride. The proposed standard would establish an eight-hour time-weighted average exposure limit of 25 parts per million (ppm), as well as a short-term exposure limit of 125 ppm determined from a 15 minute sampling period. That is a sharp reduction from the current limit of 500 ppm. The proposed standard would also set a 12.5 ppm action level (a level that would trigger periodic exposure monitoring and medical surveillance provisions.4 The National Institute for Occupational Safety and Health recommends that methylene chloride be regarded as a "potential occupational carcinogen." NIOSH further recommends That occupational exposure to methylene chloride be controlled to the lowest feasible limit. This recommendation was based on the observation of cancers and tumors in both rats and mice exposed 10 methylene chloride in air.5 How Can I Be Exposed to Methylene Chloride while Stripping Furniture? Methylene chloride can be inhaled when vapors are in the air. Inhalation of the methylene chloride vapors is generally The most important source of exposure. Methylene chloride evaporates quicker than most chemicals. The odor threshold of methylene chloride is 300 ppm.6 Therefore, once you smell methylene chloride, you are being over-exposed. Pouring, moving. or stirring the chemical will increase the ra1e of evaporation. Methylene chloride can be absorbed through the skin either by directly touching the chemical or through your gloves. Methylene chloride can be swallowed if it gets on your hands, clothes, or beard, or if food or drinks become contaminated. How Can Breathing Exposures be Reduced? Install a Local Exhaust Ventilation System: Local exhaust ventilation can be used to control exposures. Local exhaust ventilation systems

Includes a diagram of a slot hood for dip tank with the caption: Figure 3 - Slot Hood for Dip Tank. Text: capture contaminated air from the source before it spreads into the workers' breathing zone.7 If engineering controls are not effective, only a self-contained breathing apparatus equipped with a full facepiece and operated in a positive-pressure mode or a supplied-air respirator affords the necessary level of protection. Air-purifying respirators such as organic vapor cartridges can only be used for escape situations.8 A local exhaust system consists of the following: a hood, a fan, ductwork, and a replacement air system.9, 10, 11 Two processes are commonly used in furniture stripping: flow-over and dip tanks. For flow-over systems there are two common local exhaust controls for methylene chloride - a slot hood and a downdraft hood. A slot hood of different design is most often used for dip tanks. (See Figures 1, 2, and 3) The hood is made of sheet metal and connected to the tank. All designs require a centrifugal fan to exhaust the fumes, ductwork connecting the hood and the fan, and a replacement air system to bring conditioned air into the building to replace the air exhausted. In constructing or designing a slot or downdraft hood, use the following data: Slot hood (Figure 1): At least 2200 cf1n per 8' X 4' tank. 1 -2 inch slots. Slot velocity - 1000 fpm. 3 - 5 slots. Plenum at least 1 foot deep. Downdraft hood (Figure2): At least 1600 cfm per 8' X 4' tank. Plenum at leasl 9" deep. Slot hood for Dip Tank (Figure 3): At least 2900 cfm per 8' X 4' tank. 3/4" slot that runs the length of the front and back of the tank. Slot velocity - 3200 fpm. Plenum on the sides of the tank should be 6" deep by 36" long. 12" duct leads from the center of the front plenum to the fan. Safe work practices: Workers can lower exposures by decreasing their access to the methylene chloride.12 1) Turn on dip tank control system several minutes before entering the stripping area. 2) Avoid unnecessary transferring or moving of stripping solution. 3) Keep face out of the air stream between the solution-covered furniture and the exhaust system. 4) Keep face out of vapor zone above the stripping solution and dip tank. 5) Retrieve dropped items with a long handled tool. 6) Keep the solution recycling system off when not in use. Cover reservoir for recycling system. 7) Cover dip tank when not in use. 8) Provide adequate ventilation for rinse area.

How Can Skin Exposures be Reduced? Skin exposures can be reduced by wearing gloves whenever you are in contact with the stripping solution.13 1) Two gloves should be worn. The inner glove should be made from polyethylene/ethylene vinyl alcohol (e.g. Silver Shield®, or 4H®). This material, however, does not provide good physical resistance against tears. so an outer glove made front nitrile or neoprene should be worn. 2) Shoulder-length gloves will be more protective. 3) Change gloves before the break-through time occurs. Rotate several pairs of gloves throughout the day. Let the gloves dry in a warm well ventilated area at least over night before reuse. 4) Keep gloves clean by rinsing often. Keep gloves in good condition. Inspect the gloves before use for pin-holes, cracks, thin spots, and stiffer than normal or sticky surfaces. 5) Wear a face shield or goggles to protect face and eyes. What Other Problems Occur? Stripping Solution Temperature: Most manufacturers of stripping solution recommend controlling the solution to a temperature of 70°F. This temperature is required for the wax in the solution to form a vapor barrier on top of the solution to keep the solution from evaporating too quickly. If the temperature is too high, the wax will not form the vapor barrier. If it is too cold. the wax will solidify and separate from the solvent causing increased evaporation. Use a belt heater to heat the solution to the correct temperature. Call your solution manufacturer for the correct temperature for your solution.14 Make-Up Air: Air will enter a building in an amount to equal the amount of air exhausted whether or not provision is made for this replacement. If a local exhaust system is added a make-up or replacement air system must be added to replace the air removed. Without a replacement air system, air will enter the building through cracks causing uncontrollable eddy currents. If the building perimeter is tightly sealed, it will prevent the air from entering and severely decrease the amount exhausted from the ventilation system. This will cause the building to be under negative pressure and decrease the performance of the exhaust system.15 Dilution Ventilation: With general or dilution ventilation, uncontaminated air is moved through the workroom by means of fans or open windows, which dilutes the pollutants in the air. Dilution ventilation does not provide effective protection to other workers and does not confine the methylene chloride vapors to one area.16 Phosgene Poisoning from Use of Kerosene Heaters: Do not use kerosene heaters or other open flame heaters while stripping furniture. Use of kerosene heaters in connection with methylene chloride can create lethal or dangerous concentrations of phosgene. Methylene chloride vapor is mixed with the air used for the combustion of kerosene in kerosene stoves. The vapor thus passes through the flames, coming into close contact with carbon monoxide at high temperatures. Any chlorine fanned by decomposition may, under these conditions, react with carbon monoxide and form phosgene.17

REFERENCES: 1 Halogenated Solvents industry Alliance and Consumer Product Safety Commission [1990] Stripping paint from wood (Pamphlet for consumers on how to strip furniture and precautions. to take). Washington DC: Consumer Product Safety Commission. 2 Ibid. 3 NIOSH [1992]. NIOSH Testimony on Occupational Safety and Health Administration's proposed rule on occupational exposure to methylene chloride, September 21, 1992. OSHA Docket No. H-71 NIOSH policy statements. Cincinnati OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health. 4 56 Fed. Reg. 57036 [1991] . Occupational Safety and Health Administration: Proposed rule on occupational exposure to methylene chloride. 5 NIOSH [1992]. 6 Kirk, R.E. and P.F. Othmer, Eds [1978] Encyclopedia of Chemical Technology 3rd Ed., Vol. 5:690, New York: John Wiley & Sons, Inc. 7 ACGIH [1988]. Industrial Ventilation; A Manual of Recommended Practice. 20th Ed. Cincinnati OH: American Conference of Governmental Industrial Hygienists. 8 NIOSH [1992]. 9 Fairfield CL. and A.A. Beasley [1991]. In-depth Survey Report at the Association for Retarded Citizens, Meadowlands, PA. The Control of Methylene Chloride During Furniture Stripping. Cincinnati OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health. 10 Fairfield, C.L. [1991]. In-depth Survey Report at the J.M. Murray Center. Cortland, NY. The control of Methylene Chloride During Furniture Stripping. Cincinnati OH.: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health. 11 Hall, R.M., K.F. Martinez, and P.A. Jensen [1992]. In-Depth Survey Report at Tri-County Furniture Stripping and Refinishing, Cincinnati, OH. The Control of Methy1ene Chloride During Furniture Stripping. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health. 12 Fairfield C.L. and A.A. Beasley [1991]. In-Depth Survey Report at the Association for Retarded Citizens, Meadowlands, PA. The Control of Methylene Chloride During Furniture Stripping. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health. 13 Roder, M. [1991]. Memorandum of March 11, 1991 from Michael Roder of the Division of Safety Research, to Cheryl L. Fairfield of The Division of Physical Sciences and Engineering. National Institute for Occupational Safety and Health, Centers for Disease Control, Public Health Service, and U.S. Department of Health and Human Services 14 Kwick Kleen Industrial Solvents, Inc. [1981]. Operations Manual, Kwick Kleen Industrial Solvents, Inc., Vincennes, IN. 15 ACGIH [1988]. 16 Ibid. 17 Gerritsen, W.B. and C.H. Buschmann [1960]. Phosgene Poisoning Caused by the Use of Chemical Paint Removers containing Methylene Chloride in Ill-Ventilated Rooms Heated by Kerosene Stoves. British Journal of Industrial Medicine 17:187. Where Should I go for More Information? The NIOSH 800- number is a toll-free technical information service that provides convenient public access to NIOSH and its information resources. Callers may request information about any aspect of occupational safety and health. 1-800-35-NIOSH (1-800-356-4674)

[62 FR 1493, Jan. 10, 1997]