American Furniture Warehouse (AFW) Compark Megastore

Company: American Furniture Warehouse (AFW) Compark Megastore

NAICS Code: Furniture stores (e.g., household, office, outdoor)

Task: Furniture assembly, repair, and delivery.

Employees: 767

Success Brief:

Instances of strain, sprain, and other injuries related to poor ergonomics and repetitive motion were reduced through enhanced training, technique modification, use of assistive devices, and audits.

The Problem:

A review of the company's OSHA 300 logs revealed many injuries such as sprains, strains, and other musculoskeletal injuries among employees who regularly move, lift, and maneuver large pieces of furniture. Injuries resulted in lost work days, restricted duty, or temporary reassignment. Days Away, Restricted, and Transferred (DART) and Total Recordable Cases (TRC) rates were calculated for the facility for the years 2013-2015. These rates were compared to the Bureau of Labor Statistics rates for the industry NAICS code 442100; Furniture Stores. Rates for each of the three years exceeded the industry average. Injuries related to ergonomics risk factors such as force, repetition, and posture for the Compark Megastore accounted for greater than half of all recorded injuries for each year. OSHA sent the company an Ergonomic Hazard Alert Letter (EHAL) which contained a summary of the injury data statistics and recommendations for improvement.

The Solution:

During the year following receipt of the EHAL from OSHA, the company took steps to improve or in some cases developed the following aspects of their health, safety, and ergonomics program. In this type of industry, there generally is no single intervention that solves the problem. Many smaller interventions are knit together to create a programmatic approach. Below are examples of strategies AFW employed:

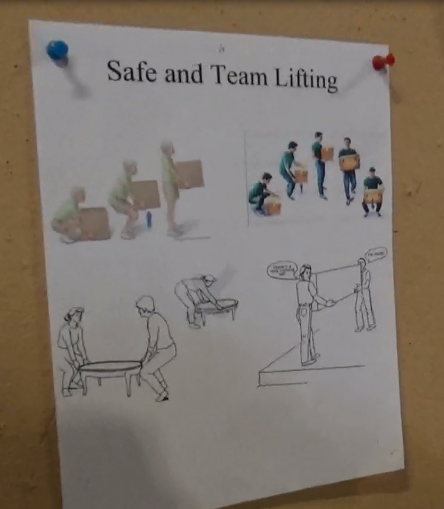

- AFW encourages and empowers employees to assess every situation and use a variety of techniques to obtain optimum success when handling product. This policy is enforced by management, and employees are required to follow the hierarchy of controls to eliminate lifting by using mechanical aids when possible. When heavy and/or large pieces must be handled manually, employees are required to team lift. They narrate each step throughout the process before executing the lift and continually communicate while they lift. Floor managers continually observe and coach employees.

- AFW implemented an enhanced ergonomics training program for managers to ensure they know how to coach employees on proper lifting techniques. This training also enhances their ability to perform in-depth ergonomics audits and make corrections where needed.

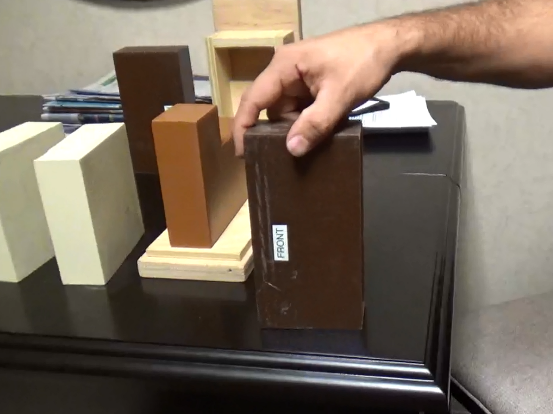

- AFW developed a series of videos with visual aids for employees and managers. These videos demonstrate safe lifting techniques and help identify issues such as center of gravity and safe lifting points. The blocks are scale mockups of the items frequently encountered in the warehouse and during delivery operations.

- AFW made available a variety of assistive equipment such as carts, dollies, and hand trucks at locations throughout the warehouse.

- AFW encouraged and empowered employees to "stop and correct" others when they observe improper lifting and handling that could result in injury.

- AFW developed an anonymous reporting system for employees to report safety and health concerns.

- AFW implemented more detailed accident investigations and is developing enhanced root cause analysis tools.

- AFW performs frequent inspections of equipment and tools, and repairs or replaces items with damage.

- AFW's Environment, Health and Safety coordinator and management perform regular safety walks. Department managers and employees perform weekly micro audits. These audits are designed to interact with the employee to correct behaviors or promote positive reinforcement through coaching.

- AFW allows mini breaks and rest periods as needed.

- AFW drivers and delivery employees go out in teams of at least two. They are trained to assess the delivery area for unsafe conditions such as: icy driveways and sidewalks, uneven surfaces, and items that are in their delivery path. Delivery employees are encouraged to determine the safest delivery route to prevent accidents and injury. If there is an unsafe condition that cannot be corrected or maneuvered around, then the employee is required to call their manager immediately.

The Impact:

The injury and illness DART rate has dropped by over 60% since the company instituted its program. The rate for 2015 was 12.4. The rate for 2016 the rate was 10.1, and from January 1 to October 31 of 2017 it was 4.1. Employees are satisfied with the changes and indicate that they feel empowered to report unsafe behaviors and raise concerns. They appreciated the efforts the company has made to raise the understanding about ergonomic risk factors and the ability they now have to help protect themselves.