Ceradyne, Inc. Works with On-site Consultation to Significantly Improve Incident Rate and Achieves SHARP Recognition

Company: Ceradyne, Inc.

Location: Lexington, Kentucky

Employees: Approximately 220 full time employees including production, supervisors and corporate personnel

Success Brief:

In 2004, Ceradyne, Inc. began working with the Kentucky Occupational Safety and Health (OSH) Program's On-site Consultation Program as part of the company's efforts to enhance safety and health performance, including the reduction of injuries and illnesses at the plant. As a result of the assistance the facility received, the site realized improvements to its safety and health management program and achieved recognition in the On-site Consultation Program's Safety and Health Achievement Recognition Program (SHARP) on June 15, 2010.

Company Description:

Ceradyne, Inc. develops and produces advanced technical ceramic solutions for applications in automotive/engine, oil and gas, nuclear power, industrial wear, medical, electronic and defense industries (NAICS 327999, "Other Miscellaneous Nonmetallic Mineral Product Mfg.").

The Situation:

In 2004, Ceradyne, Inc. started operations at its Lexington, Kentucky facility. During start up, the site experienced a high number of injuries. In 2005 and 2006, Ceradyne experienced a dramatic increase of employees and employee turnover in a matter of a few months. The site hired an estimated 1800 employees to finally retain the 300 employees needed to commence start up operations.

In addition, in 2006, the Kentucky OSH Program conducted numerous enforcement inspections at the Ceradyne Lexington facility. Many of the inspections were a result of formal employee complaints and related to hazards associated with combustible dust, respiratory protection, housekeeping and electrical equipment. As a result of the inspections, the Kentucky OSH Program issued several serious and other than serious violations to Ceradyne. Ceradyne made a concerted effort to address the concerns and abate the hazards as soon as possible. The Kentucky OSH Program's Division of Compliance staff also suggested to the facility that Ceradyne's management team in Lexington contact the Kentucky OSH Program's Division of Training and Education to seek assistance with developing a safety and health program. This division administers the On-site Consultation Program in the state.

As a result, the company decided to explore programs offered by the Kentucky OSH Program which might assist them in improving safety and health performance at the site. According to Ceradyne's Corporate Vice President, Jeff Waldal, "Ceradyne was motivated to establish a solid safety and health management program in order to reduce the negative impacts of numerous injuries to our employees."

The Solution:

In 2006, Ceradyne contacted the Kentucky OSH Program's On-site Consultation Program to request a visit and to learn more about the On-site Consultation Program's Safety and Health Achievement Recognition Program (SHARP). John Lippert, SHARP Program Manager, Kentucky OSH Program's On-site Consultation met with Dustin Spencer, Safety Manager, Phillip Campbell, Safety Supervisor and Justin Barnes, Safety Technician. He presented information on what the benefits to companies and their workers are of pursuing and being recognized in SHARP. "The requirements to participate in SHARP gave Ceradyne a clear direction and focus while also establishing checks and balances to keep us honest and improve the safety culture. It made good business sense to proceed with achieving SHARP recognition," said Waldal.

Ceradyne began to take steps to turn around the site's safety and health culture and implement a safety and health management program. The facility established and communicated to all employees a Core Values document; spent extensive amounts of time and effort to develop and deliver training including the use of high impact techniques for fall protection and confined space simulations with an outside safety consultant; and continually updated employees on what Ceradyne was doing and spending to improve safety conditions. Zero Tolerance for violations of safety rules were needed to get everyone's attention and realize Ceradyne was serious about changing behaviors. Communication on what average incident costs and how injuries affect employee's lives and impact business operations are communicated in plant-wide meetings. For example, the number of body armor billets needed to recoup costs of an incident were presented.

The Ceradyne Lexington facility was certified in ISO 9001 in 2008. The facility recognized the process to obtain ISO 9001 certification paralleled the systems approach to safety and health required to achieve SHARP status. While Ceradyne's initial attempts to achieve SHARP recognition in 2008 were not successful, the site worked closely with the Kentucky OSH Program's On-site Consultation Program staff to get guidance and assistance on implementing its safety and health management program. As a result of its efforts, Ceradyne achieved SHARP recognition on June 15, 2010.

Kentucky's Labor Secretary J.R. Gray presented the award to Waldal. "It's not easy to become SHARP-certified," said Secretary Gray. "Companies must be thoroughly assessed by Kentucky Occupational Safety and Health consultants, have injury and illness rates below national averages for its industry, and maintain a safety and health program that involves all employees in finding and correcting existing or possible future hazards as they develop."

The Impact:

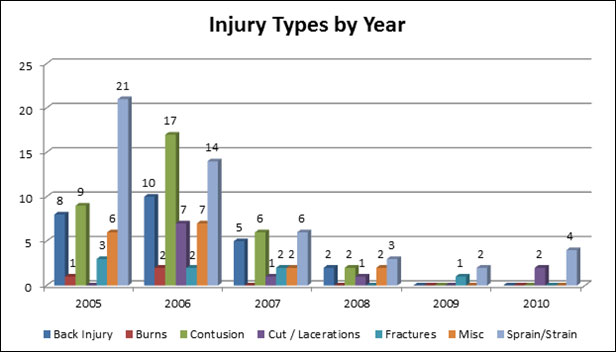

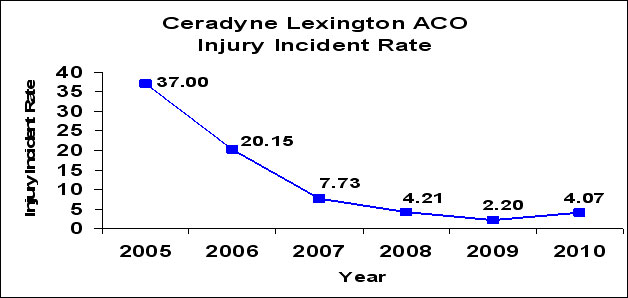

"By applying the principles of SHARP to the site's unique challenges, Ceradyne and OSHA were able to form an effective collaboration that made a huge difference in operations at our Lexington Facility" said Waldal. Dramatic decreases in incident rates were achieved through this successful cooperative process, and Ceradyne's employees reaped the benefits of a safer workplace. Within a five year period, the Ceradyne Lexington facility decreased their injury incidence rate to less than 20% of the site's rate prior to receiving assistance from Kentucky On-site Consultation.

In addition, Ceradyne has taken on a leadership role in encouraging other companies involved in or interested in SHARP to network and share best practices. On November 17th, 2011 Ceradyne's Lexington facility hosted the first ever gathering of Kentucky employers which have received or are interested in obtaining SHARP recognition. The one-day seminar focused on electrical safety. Numerous SHARP certified worksites, as well as those interested in participating in SHARP, along with government officials and vendors shared best practices, established networking opportunities and expressed their commitment to help each other become better in managing their employee's safety and health.

"Ceradyne strongly supports partnership programs such as SHARP and VPP and is committed to participating in these processes for the betterment of our employees and their families. The SHARP process is a direct part of our North American EHS Strategy as we move forward to have the best possible Safety management system at all of our facilities." Tony Ewing, North American EHS Director.

Source:

Mr. Tony Ewing, North American Environment, Health and Safety Director, Ceradyne

As of January 2012