DeBourgh Continues to Realize Safety and Health Improvements through Working with Colorado On-site Consultation Program

Company: DeBourgh Manufacturing Company

Location: La Junta, Colorado

Employees: 110 workers

Success Brief:

DeBourgh Manufacturing Company (DeBourgh) began working with the Colorado On-site Consultation Program in the mid 1990's and was initially approved for participation in the Safety and Health Achievement Recognition Program (SHARP) in 2000. Over the years, by working with the Colorado On-site Consultation Program's consultants, DeBourgh received assistance that made it a safer, healthier and happier place to work and reduced its injury and illness rates and workmen's compensation costs.

Company Description:

DeBourgh Manufacturing Company is a metal fabricator (NAICS 337215) of athletic and military storage lockers for educational, military, and industrial institutions in the domestic and foreign markets. The company has approximately 110 employees and is located in La Junta, Colorado.

The Situation:

In the early 1990's, DeBourgh realized it needed to improve its safety and health performance. DeBourgh provided minimal and limited training to the employees and experienced approximately thirty injuries per year. In the mid 1990's, Occupational Safety and Health Administration (OSHA) referred the company to the Agency' former Cooperative Compliance Program (CCP), because of the company's high illness and injury rates. The former CCP was designed to give businesses which experienced high injury and illness rates the opportunity to reduce the likelihood of an OSHA enforcement inspection by developing stringent safety policies and programs. DeBourgh knew the company needed assistance.

The Solution:

In the mid 1990's, DeBourgh requested a visit from the Colorado On-site Consultation Program to identify hazards and evaluate all aspects of the company's safety and health management system. The on-site consultation team confirmed that DeBourgh had multiple safety and health issues and needed assistance. In the first visit, the consultants identified 27 hazards. After the visit, DeBourgh shifted gears and began the transformation of the company's safety culture. DeBourgh turned its attention to focus on preventing hazards and began to accentuate the importance of safety.

DeBourgh continued to work with the Colorado On-site Consultation Program and in the late 1990's, the consultants conducted several OSHA compliance presentations and assisted the company in developing and implementing its own training program. By the early 2000's, DeBourgh had greatly improved safety and health awareness and was approved for the Safety and Health Achievement Recognition Program (SHARP) in 2003.

Since the site's approval to SHARP, the company established a safety and health team with management and hourly worker representation. The team created the following list of company values: Safety, Quality, Honestly, Team Work, Clear Communications, and Treating People Fairly.

To maintain a safe workplace, DeBourgh officials are actively involved in the site's safety and health program's implementation through conducting daily walkthroughs and monthly employee meetings. Furthermore, DeBourgh conducts formal audits and self-inspections monthly, quarterly and annually by different levels of supervision, including Line Supervisors, the Safety Committee and the Plant Advisory Committee. All injury incidents are thoroughly evaluated by root cause analysis, re-enactment and a Safety Team Review.

According to Ms. Patty Jefferies, Colorado On-site Consultation Program's consultant, "DeBourgh's hazard corrections are tracked through maintenance check-sheets and receive the personal attention of the Vice President for Operations." Additionally, DeBourgh continues to perform change analyses that have resulted in the implementation of local capture ventilation, machine guarding, maintenance requirements, and noise exposure monitoring for specific processes and machinery. Personal protective equipment use and engineering controls are outstanding, according to Ms. Jefferies.

After working with the consultant, DeBourgh obtained a greater level of awareness and understanding of the significance of an effective safety and health management program, especially in the areas of workplace documentation and training. Ms. Jefferies said, "DeBourgh's employee training vastly exceeded OSHA standards. The company's new-hire training is most impressive and their training records are impeccable." The company has established a continual employee safety evaluation system. New employees receive 30, 60 and 90 days written evaluations which include information on safety performance and requests for feedback on training received. In addition to covering all appropriate OSHA topics, DeBourgh expanded its employee training to address issues related to environmental safety, Resource Conservation and Recovery Act, and Department of Transportation requirements.

According to Ms. Jefferies, DeBourgh's Emergency Preparedness program is a model program. The plant conducts emergency drills, involves the local fire department and has a company trained First Aid Team made up of volunteers. In addition, DeBourgh has expanded it safety housekeeping efforts. Further, DeBourgh has implemented lean manufacturing methods and process re-engineering.

Because of DeBourgh's continued efforts to improve its safety and health program implementation and performance, on February 2, 2011, DeBourgh received its recertification for continued participation in SHARP and celebrated its eighth year of SHARP status

The Impact:

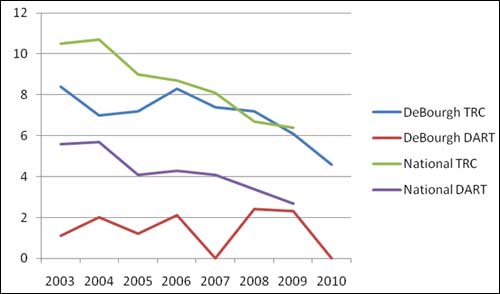

In 2000, DeBourgh achieved SHARP recognition and has continually maintained a low injury and illness rates ever since. In the early to mid 1900s the company's Day Away, Restricted or Transferred (DART) rate was above 10 and Total Recordable Case (TRC) rate was 31.0. In 2010, the site achieved a DART of zero and TRC of 4.6. The 2009 Bureau of Labor Statistics national industry average DART rate and TRC rate for NAICS 337215 was 2.7 was 6.4 respectively.

On February 2, 2011, DeBourgh received its re-certification for SHARP participation from the Colorado On-site Consultation Program. According to Ms. Jefferies, following the recognition ceremony that day, DeBourgh employee's expressed their satisfaction with the company's safety and health protections. One employee stated at the time, "I have worked at three fairly large companies. By far, DeBourgh is the safest. At DeBourgh, employees are part of the family." Rob Berg, DeBourgh's President and CEO, statement at the end of each monthly safety meeting reflects the company's commitment to safety and health and its employees. Mr. Berg concludes these gatherings saying, "There is nothing more important than the safety of our team members so please work smart and work safe." Based on the Colorado On-site Consultation Program's experience working with DeBourgh since 1999, Ms. Jeffries believes the company continues to excel in all areas of safety and health management. She stated, "Employee safety remains a strong culture and Berg family value - on equal footing with productivity and quality."

Source:

Ms. Patty Jeffries, M.S., CIH, Industrial Hygiene Consultant, Colorado State University, Occupational Health and Safety Consultation (March 2011)