Honda of America Manufacturing, Inc.

State: Ohio

Company: Honda of America Manufacturing, Inc., Marysville, Ohio

Industry: Auto Manufacturing - SIC Code: 3711

Employees: 12,500

Success Brief:

On the rear suspension process located on the automobile assembly line, production associates developed a spring-loaded tool fixture for use during the "link arm" tightening segment. This tool fixture greatly reduced the removal pull force and improved cycle time, scrap rate and associate morale.

The Problem:

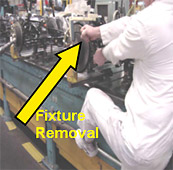

Production associates had difficulty removing the old manual tool fixture because it jammed when used to install the "link arm" to the rear suspension of the car. The pull force required to remove the jammed tool fixture averaged 133 lbs. Four injuries to fingers and hands had occurred during the removal of the jammed tool fixture over a 12-month period.

Tool fixture is large and bulky.

Large amount of force is necessary to remove the jammed tool fixture.

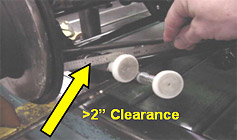

Tool fixture creates a clearance issue between the fixture and the part.

The Solution:

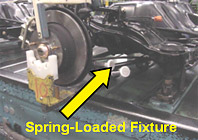

Honda production associates developed a new spring-loaded tool fixture from "off-the-shelf" materials fabricated in-house. Total estimated development cost for the new tool was $200.

New spring-loaded fixture is smaller and easier to use.

New fixture releases away from the part and does not create a clearance issue.

2.2 lbs. of pull force is required to remove the new fixture.

The Impact:

By using the new spring-loaded tool fixture during the "link arm" tightening segment of the process, the following improvements were realized:

- reduction in removal pull force from an average of 133 lbs to 2.2 lbs,

- 10-percent reduction in cycle time,

- 96-percent reduction in scrap, and

- 60-percent increase in associate confidence rate (morale) to complete the process.

Since the implementation of the new fixture, no injuries have occurred. The estimated cost savings from quality, cycle time, and injury avoidance is approximately $1 million.

Source:

- Team of Production Associates from Marysville Automobile Plant, Honda of America Mfg., Inc. (June 2006).