Honda of America Mfg., Inc.: Motorized Carts and Racks

State: Ohio

Company: Honda of America Manufacturing, Inc., Marysville, Ohio

Industry: Auto Manufacturing - SIC Code: 3711

Employees: 12,500

Success Brief:

Associates used existing motorized vehicles to try to move heavy carts and racks, but the vehicles were too big and the effort took too much time. Through experimentation and testing, a team of associates designed a simple innovative system to eliminate the high initial push/pull force necessary to move a cart loaded with cargo. The new system consists of an electric motor and clutch assembly, a control box and a directional control switch and can be retrofitted on existing delivery carts and racks. When an associate turns the switch to the "on" position, the motor supplies power to one of the wheels of the cart. To date, the system is not only eliminating injuries, but it is also carrying heavier loads on the cart.

The Problem:

Maximizing the number of parts loaded onto each cart or rack is a priority, even though the carts and racks can weigh more than 1,000 pounds and require high initial push/pull forces to start them moving. Associates move these carts manually to the appropriate delivery stations on the production floor. Honda of America realized that it was annually investing about $310,000 for carts and the injuries associated with them. (See Figures 1A and 1B.)

Figures 1A and 1B. Examples of Manually Pushing/Pulling Heavy (>1,000 lbs.) Carts.

The Solution:

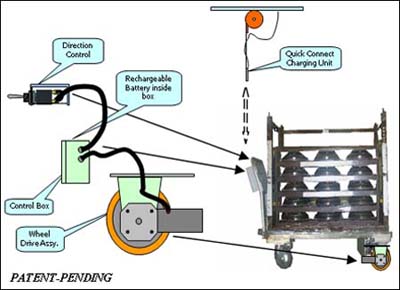

The team of associates devised a new system to overcome the high initial force required to start the cart moving. The system includes a motor and clutch mounted on one of the wheels of the cart. (See Figure 2.) To activate the system, an associate turns on a directional switch located on a control box mounted near the handles of the cart. The switch activates a timer that times out after overcoming the initial force required to start the cart moving. The timer prevents the motor from running continuously, which reduces the potential for a run-away cart and prolongs the life of the battery. (See Figure 3.)

Figure 2. The New System Mounted on a Cart.

Figure 3. Schematic of the New System.

The Impact:

Since April 2007, the Engine Assembly Department in the Anna, Ohio plant has installed 22 new cart systems in five different areas. As of October 2007, plant managers have reported no push/pull related injuries at any of these areas. The new systems have eliminated any manual push/pull force over 50 pounds--in some cases they have eliminated it entirely. The team created 22 new cart systems that they fabricated out of new racks and cart bases; they did not retrofit the old carts because new carts were less expensive, had separate wheel assemblies that could be added cost effectively, could carry much more weight, and required less push/pull to initiate movement. In addition, the new carts yielded a 5-year return on investment of $1,464,560.

Over the next 2 years, Honda plans to implement the new cart system at other process areas not only at this facility but also at other Honda manufacturing plants. Honda expects similar returns on investment for these future applications of the new cart system.

Source:

- Team of associates from the Anna Engine Plant, Honda of America Mfg., Inc. (September 2008).