AK Steel Corporation's Mansfield Plant Partnership and Toledo Area Office Host Successful Safety and Health Foundry Seminar

AK Steel Plant, Mansfield, Ohio

AK Steel's Personal Protection Equipment (PPE) vendor and AK Steels PPE used in the mill. Notice the OSP poster on the right hand side!

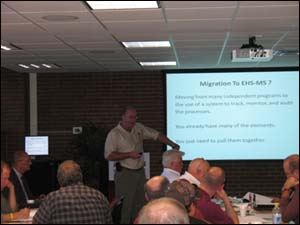

Todd Jensen, Toledo Area Office CSHO, conducting training.

Bob Sterling, Auburn Environmental, discussing environmental SHMS.

Background:

Since 1971 OSHA has been conducting inspections of foundries and identifying safety and health hazards. Almost 40 years later, much still needs to be done to improve workers safety and health, resulting in OSHA continuing to identify the same kinds of foundry safety and health hazards. Last September, the AK Steel Corporation's Mansfield Plant OSHA Strategic Partnership (OSP) and the OSHA Toledo Area Office in Region V decided to do something about it.

First, the Director of the Toledo Area Office sent out an invitation letter to all foundries in the state of Ohio using the Ohio Manufacturing Guide which lists all industries in the state based on Standard Industrial Classification (SIC) code. Approximately 250 foundries were invited. The invitation letter included the following questions:

- Are your employees wearing the proper protective equipment when working around molten metal or when exposed to electrical hazards?

- Is your respiratory protection program properly implemented?

- Is lockout properly performed when setting up molding machines or cleaning sand mullers?

- Are employees exposed to fall hazards in excess of four feet when working on equipment or standing on sand molds?

- What chemical inhalation and contact hazards should I anticipate for my routine production operations?

Then the companies were invited to attend a free, one-day informational foundry seminar on October 22, 2008, hosted by the AK Steel Corporation's Mansfield Plant OSHA Strategic Partnership (OSP) and the Toledo Area Office in Region V. The main purpose of the seminar was to help foundries in Ohio identify and correct workplace hazards before a serious injury occurred, and teach participants how wearing proper personal protective equipment (PPE) can save the lives of foundry workers.

Seminar speakers included Todd Jenson, Compliance Officer, Toledo Area Office; Sterling, Certified Industrial Hygienist, Auburn Environmental; Bob Nicholson, Electrical Designer, JDRM Engineering; and Scott Feil, Assistant Area Director, Toledo Area Office. Safety professionals from AK Steel, Onsite Consultation, and the Ohio Bureau of Workers' Compensation (BWC) were also available to answer questions and provide information on safety and health hazards affecting foundry workers.

Success Impact:

Feedback - Seminar Attendee Testimonials

A key seminar topic included common hazards found in foundries and appropriate corrective measures; lockout, confined space, protective equipment, machine guarding, cranes, hearing conservation, silica, respiratory protection, and heavy metals. Other topics addressed included how to develop and implement effective safety and health management systems (SHMS), how the National Fire Protection Association (NFPA) Standard 70E (Electrical Safety in the Workplace) applies to OSHA regulations, and best ergonomic practices. Attendees provided very positive feedback about the seminar. Examples of some of the attendees' testimonials included the following:

"My only wish is that they would have had this kind of program before…Unfortunately there are a lot of people in this industry that have not been educated in these processes as they have been brought through a system that did not keep up to the standards which multiplies the problem…these seminars will help open eyes and educate hopefully before a disaster strikes…I would say that you will see more interest next year once word of mouth gets out about today's presentations. Good Job."

"I liked discussions with different companies and their employees, variety of presentations, and the frankness of OSHA."

"Enthusiasm of the presenters, topics were right on target, expertise of presenters. It was a great event that promoted AK Steel and OSHA. Furnace personal protection equipment (PPE)/pouring PPE considerations - easy to understand, copies of presentation…Excellent base of information which was directly applicable to our company, helped me identify areas for improvement and for additional training, great job."

"All presentations were very good. I liked presentation on what OSHA's seeing. Interacting with others and sharing information and making new contacts was maybe the best thing. I applaud OSHA for pulling this together."

"Excellent speakers, great facilities, interesting interaction with participants."

"This was one of the best ideas of OSHA outreach to employers. This program brought in resources to employers like outside contractors and offered safety contacts like BWC. Continue the education as a team approach to safety by BWC, OSHA, and safety contractors. Great Job!"

"Presenters were excellent, great examples, practical take always."

"I liked the overview in the first presentation which was pretty much a wall to wall of concerns in the foundry. It was also good to see the standards and resources that compliance officers consult. The NFPA presentation was very thorough and way informative. I got a lot of resources to use for reference."

"Excellent Presentations."

"I thought the entire program was very informative, great job."

Over 65 representatives from 35 different foundries and related companies were in attendance–not only from the state of Ohio–but also from Kansas, Missouri, West Virginia, and North Carolina. Due to the overall success and positive feedback about the seminar, the Toledo Area Office has decided to make the foundry seminar an annual event.

Partnership Objectives:

The key objectives of the OSP are to reduce worker injury and illness rates through the development, implementation, and maintenance of effective SHMS that focus on reducing key hazards; increase employee involvement; and conduct monthly safety audits to identify and eliminate employee exposure to hazards. A couple of informal goals of the OSP are to develop a better working relationship between AK Steel, the union, and OSHA, and consider attaining Voluntary Protection Programs (VPP) status, OSHA's premier recognition program, in the future.