Hurricane eMatrix

List of Activity Sheets » Operation-specific sheets

Work Zone Safety and Traffic Control within a Work Area

This picture shows actual disaster site work conditions and may not illustrate proper safety and health procedures.

Activity Description

- This activity sheet is for all individuals who will work in and around roadways while conducting response and recovery operations (e.g., tree trimming, debris collection) and may need to set up work zones as protection from oncoming vehicular traffic. It is also for response and recovery workers operating or working near heavy equipment who will need to establish and follow traffic safety procedures to avoid injury and equipment damage.

- For some operations or situations other activity sheets also apply; see related activity sheets below.

- As a result of Hurricanes Katrina and Rita (2005), water, sand, and sludge have impacted streets and buildings causing many to become structurally unsound and in need of assessment and repair. In addition, the high winds and floodwaters left extensive amounts of debris, which will require clearing. To address these conditions, many operations will be conducted in roadways, where response and recovery workers may be exposed to vehicular traffic. In addition, heavy equipment (bulldozers, backhoes, front-end loaders, dump trucks, aerial lifts) will be used extensively during most operations, exposing the response and recovery workers in and around the equipment to struck-by hazards.

- While OSHA requires that operators be familiar with the pieces of machinery they operate, there is also a need to implement controls to ensure these activities are performed safely. Controls are needed where multiple pieces of heavy equipment, vehicles, and response and recovery workers are in close proximity.

- Response and recovery workers conducting this operation may be employed by Federal, State, local, and private employers. Review How to Use This Matrix in the introduction for a discussion of how this information may apply to different workers.

About the Activity Sheet

This activity sheet does not provide an in-depth analysis of OSHA standards and regulations and cannot address all hazards. It does not increase or diminish any OSHA requirement or employer obligation under those requirements. It is intended as a guide and quick reference for employers and response and recovery workers. The Matrix captures major activities involved in hurricane response and recovery, highlights many of the hazards associated with them, and recommends beneficial work practices, personal protective equipment (PPE), and other exposure control methods. Employers must evaluate the specific hazards associated with the job/operation at the site where the work is being performed.

Employers are responsible for providing a safe and healthful workplace for their workers. OSHA's role is to assure the safety and health of America's workers by setting and enforcing standards; providing training, outreach, and education; establishing partnerships; and encouraging continual improvement in workplace safety and health.

The Hazard Exposure and Risk Assessment Matrix for Hurricane Response and Recovery Work provides a general overview of particular topics related to current OSHA standards. It does not alter or determine compliance responsibilities in OSHA standards or the Occupational Safety and Health Act of 1970, or the equivalent State Plan standards and requirements. Because interpretations and enforcement policy may change over time, you should consult current OSHA/State Plan administrative interpretations and decisions by the Occupational Safety and Health Review Commission and the courts for additional guidance on OSHA compliance requirements. Employers should modify their procedures as appropriate when additional, relevant information becomes available.

General Recommendations

Key Engineering Controls and Work Practices. See general recommendations document.

Personal Protective Equipment. The general PPE is recommended for all response/recovery tasks/operations; only the additional PPE that may be needed for a specific hazard is noted below.

General PPE includes:

- Hard hat for overhead impact or electrical hazards

- Eye protection with side shields

- Gloves chosen for job hazards expected (e.g., heavy-duty leather work gloves for handling debris with sharp edges and/or chemical protective gloves appropriate for chemicals potentially contacted)

- ANSI-approved protective footwear

- Respiratory protection as necessary—N, R, or P95, filtering facepieces may be used for nuisance dusts (e.g., dried mud, dirt and silt) and mold (except mold remediation). Filters with a charcoal layer may be used for odors.

Recommendations Specific to Hazards Associated with Work Zone Safety and Traffic Control within a Work Area

Key Engineering Controls and Work Practices

- Develop and use a site plan that provides traffic flow details (see traffic flow diagrams; other Manual on Uniform Traffic Control Devices (MUTCD) model plans are available.

- Use flaggers, traffic cones, and/or highway channeling devices to steer traffic away from response and recovery workers along the roadway (see flagger guidance)

- Use flaggers, standard road signs (e.g., "work zone ahead"), or message boards to warn approaching vehicles of work area

- Give motorists plenty of warning of upcoming work zones; place the first warning signs at a distance calculated as 4 to 8 times (in feet) the speed limit (in MPH)-use a higher multiplier for higher speed areas (e.g., a 15 MPH road should have its first warning sign at least 60 feet from the work zone, while a work zone needed in a 65 MPH zone should have its first sign approximately 520 feet away)

- Ensure that the work zone is well lit, but control glare to avoid temporarily blinding response and recovery workers or passing motorists

Additional Personal Protective Equipment

- ANSI/ISEA 107-2004 compliant high visibility safety apparel and headwear:

- ANSI/ISEA 107-2004 specifies four performance classes of apparel or headwear that have different amounts of reflective and background material to enhance pedestrian worker visibility under a variety of work and traffic conditions. Performance classes include Classes E, 1, 2, and 3, with Class 3 providing the greatest level of visibility to a pedestrian worker (e.g., flagger). All ANSI/ISEA 107 compliant garments have retroreflective or retroreflective/fluorescent materials that encircle the wearer's torso. Additionally, ANSI/ISEA 107 compliant garments with long pants or sleeves have retroreflective or retroreflective/fluorescent materials that encircle the legs or sleeves

- Employers should perform a hazard analysis to decide which performance class is needed based on the work conditions anticipated (e.g., closeness of work area to traffic, time of day/night, weather, complexity of the background environment, pedestrian worker's task load (need to divert attention to complete other tasks), and traffic speed). This analysis is part of the PPE assessment required by 29 CFR 1910.132(d).

- Class 3 garments offer the greatest level of visibility in both complex work backgrounds and through a full range of body motion. Class 3 garments should be considered for activities where a pedestrian worker may be exposed to higher vehicle speeds and/or reduced sight distances, the pedestrian worker and vehicle operators have high task loads, or the wearer must be identifiable as a person at least one-quarter mile away

- Class 2 garments are appropriate for most hurricane response and recovery work because of the complex work backgrounds, closeness of pedestrian worker to the traffic, the need for the pedestrian worker to divert his/her attention to complete other tasks, or vehicles/equipment are traveling at speeds of 25 miles per hour (mph) or more. Class 2 garments provide better visibility than Class 1 garments by providing additional coverage of the torso

- Class 1 garments provide the minimum amount of required material needed to tell the pedestrian worker apart from the work environment. Class 1 garments are appropriate for activities where pedestrian workers can pay full attention to the approaching traffic, there is enough separation between the pedestrian worker and the vehicle traffic, the work background is not complex, and vehicles and equipment are traveling at speeds less than 25 mph

-

Class E garments are pants and shorts that have retroreflective and background materials but it may not meet minimum area or placement requirements outlined in the standard. Class E garments are not intended to be worn without a Class 2 or 3 garments

- Signaling, slow/stop signs, or wands/flashlights for flaggers providing traffic control outside the work zone

Key Engineering Controls and Work Practices

- Develop and use a site plan that provides traffic flow details

- Limit access, barricade, or set up controlled access zones where the equipment will be used; for equipment that rotates and/or carries/dumps loads, create an access zone that extends beyond the maximum rotation/swing radius of the equipment and/or beyond the area where loads will be carried/dumped

- Establish/follow traffic control patterns (e.g., cones, barrels, barricades) in work areas

- Use spotters where visibility is limited

- Do not drive in reverse gear with an obstructed rear view unless the vehicle has an audible alarm or a signaler is used

- Ensure that spotters and heavy equipment operators have communications equipment or agree on and use hand signals

- Response and recovery workers and other pedestrians should make eye contact with heavy equipment operators before proceeding near equipment or operating areas

- Train response and recovery workers not to position themselves between mechanical equipment and a fixed object

- Provide barricades around excavations and structures such as debris reduction observation towers

Additional Personal Protective Equipment

- ANSI/ISEA 107-2004 compliant high visibility safety apparel and headwear

- Signaling, slow/stop signs, or wands/flashlights for flaggers providing traffic control outside the work zone

Key Engineering Controls and Work Practices

- Inspect area for hazardous chemical containers before beginning the cleaning phase

- If hazardous chemical containers are found or leaking materials are detected:

- Do not use spark-producing devices (e.g., engines, tools, electronic, and communications equipment) in the immediate area

- Take self-protective measures (i.e., move to a safe distance upwind) and contact hazardous material response personnel for evaluation/removal before continuing work in the area

Additional Personal Protective Equipment

- Evaluate the need to revise protective clothing, respirator, and glove selection

Select any of the following potential hazards that can be associated with this activity in order to access relevant recommendations in the general recommendations document:

- Environmental hazards

Additional Medical Needs

This picture shows actual disaster site work conditions and may not illustrate proper safety and health procedures.

- Follow medical guidance and precautions outlined in the general recommendations document

Additional Training Needs

- Follow general site- and task-specific training guidelines as outlined in the general recommendations document

Related Activity Sheets

Other Resources and References

- Manual on Uniform Traffic Control Devices (MUTCD). US Department of Transportation (DOT), Federal Highway Administration (FHWA).

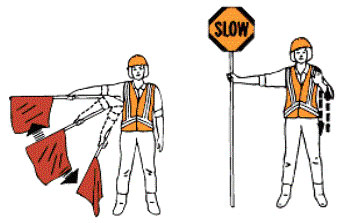

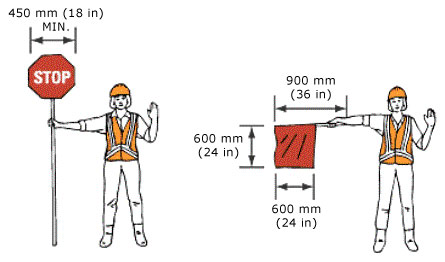

Flagger requesting vehicles STOP

A flagger should:

- Stand either on the shoulder adjacent to the road user being controlled or in the closed lane prior to stopping road users.

- Be clearly visible to the first approaching road user at all times. The flagger also should be visible to other road users.

- Be stationed sufficiently in advance of the response and recovery workers to warn them (for example, with audible warning devices such as horns or whistles) of approaching danger by out-of-control vehicles.

- Stand alone, never permitting a group of response and recovery workers to congregate around the flagger station.

Flagger requesting vehicles PROCEED SLOWLY: