Powered Industrial Trucks (Forklift) eTool

Understanding the Workplace » Narrow Aisles

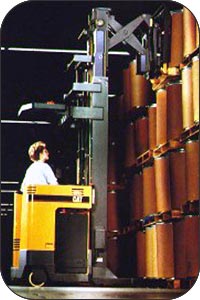

Conventional rack storage systems were designed for the counterbalanced lift truck which requires about a 12 ft (144 in) aisle width. Narrow aisle storage systems provide more storage space, but require reach trucks and order pickers to operate in much narrower aisle widths.

Reach trucks are a type of Class II electric motor narrow aisle truck. These trucks are used for high tiering, which involves storing material in multiple tiers high off the ground.

Potential Hazards

-

Danger of overloading, especially on high lift.

-

Danger of tipover.

Requirements and Recommended Practices

-

Check pallet weight before lifting.

-

Place heaviest loads on the bottom racks, and lighter loads on the top.

-

Do not exceed the load capacity of the lift truck with attachments such as a pantograph attachment. (Figure 2)

-

Do not lift the heaviest load to the maximum lift or stacking height. There may be a loss of stability.

Order picker trucks are another type of Class II electric motor narrow aisle truck. These trucks are designed to lift the operator to retrieve items.

Potential Hazards

-

Falling

Requirements and Recommended Practices

-

Wear appropriate fall protection equipment that is properly fitted and adjusted. Ensure that employees are trained in the proper use of the fall protection equipment.

Additional Information:

-

OSHA strongly encourages the use of body harnesses on elevated platforms of powered industrial trucks. OSHA Standard Interpretation: Fall protection requirements for elevated platforms of powered industrial trucks; body belts versus harnesses. (June 28, 2004)

Potential Hazards

-

Falling loads

-

Tipover

Requirements and Recommended Practices

OSHA's Powered Industrial Truck Standard includes a series of rules for safe stacking:

-

Only stable or safely arranged loads shall be handled. Caution shall be exercised when handling off-center loads which cannot be centered. [29 CFR 1910.178(o)(1)]

-

Only loads within the rated capacity of the truck shall be handled. [29 CFR 1910.178(o)(2)]

-

The long or high (including multiple-tiered) loads which may affect capacity shall be adjusted. [29 CFR 1910.178(o)(3)]

-

Trucks equipped with attachments shall be operated as partially loaded trucks when not handling a load. [29 CFR 1910.178(o)(4)]

-

A load engaging means shall be placed under the load as far as possible; the mast shall be carefully tilted backward to stabilize the load. [29 CFR 1910.178(o)(5)]

-

Extreme care shall be used when tilting the load forward or backward, particularly when high tiering. Tilting forward with load engaging means elevated shall be prohibited except to pick up a load. An elevated load shall not be tilted forward except when the load is in a deposit position over a rack or stack. When stacking or tiering, only enough backward tilt to stabilize the load shall be used. [29 CFR 1910.178(o)(6)]

In addition, the following are recommended:

-

Move forks as far apart as the load will permit. Be sure the load is centered and the forks are completely under the load before lifting.

-

When stacking use only enough backward tilt to stabilize the load.