Shipyard Employment eTool

Hot Work (including Welding, Cutting and Heating) >> Hot Work in Enclosed Spaces

Fire Watches, Establishing Rescue Teams, Ventilation, Warning Signs and Labels, and Hot Work

Hot work in shipyards is often performed in enclosed spaces that may expose workers to hazards. Listed below are the specific safety and health requirements for the majority of hot work operations. (Please see additional requirements for hot work in confined spaces and other locations.)

SSpecific Safety and Health Requirements

- Hot work operations

- Inspection and tests to maintain safe conditions

- Fall hazards

- Ventilation requirements

- Fire prevention requirements

- PPE requirements

The Confined or Enclosed Spaces and Other Dangerous Atmospheres module should be reviewed before continuing with this section. Also, this module, outlining the requirements for Hot Work in Enclosed Spaces, should be reviewed before reviewing the modules regarding hot work requirements for Confined Spaces and Other Locations.

Potential Hazards

Workers performing hot work or working in spaces adjacent to hot work are exposed to the following risks:

- Fire and explosions caused by flammable or combustible materials or airborne gases, vapors, and particulates

- Toxic gases and metal fumes produced from the hot operations (such as nitrogen oxides, and lead fumes)

- Ultraviolet radiation from electric arcs

Requirements and Example Solutions

Before beginning hot work, the following tasks must be performed:

- Review the marine chemist certificate and shipyard competent person inspection record. [29 CFR 1915.7 and 29 CFR 1915.14] If hot work permits are available, they should be reviewed.

- Ensure that the hot work surface is free of flammable and combustible materials. [29 CFR 1915.53]

-

Maintain good housekeeping conditions. [29 CFR 1915.81]

- Ensure the availability of adequate fire watches. [29 CFR 1915.504]

- See Fire Protection: Fire Watches page.

- Inspect welding and cutting equipment before use [e.g., for arc or gas welding/burning]. [29 CFR 1915.55 and 29 CFR 1915.56]

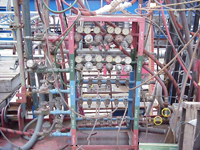

- Leak test gas torches, gauges, and hoses. [29 CFR 1915.55(g)(2)]

-

Use appropriate PPE for the welder, burner, and other exposed employees. [29 CFR 1915.51(c)(3) and 29 CFR 1915.152(a)]

- Provide UV shielding for arc welding where practical. [29 CFR 1915.56(e)]

- Remove electrodes from electrode holder when not in use. [29 CFR 1915.56(d)(1)]

- For additional requirements, see the Fire Protection chapter.

Note: When hot work is being performed, it is the employers' responsibility to ensure that precautions are taken in adjacent spaces. [29 CFR 1915.503(a)(2)]

Potential Hazard

The work space is initially inspected by a Certified Marine Chemist or a Shipyard Competent Person. Conditions may change during work so the Shipyard Competent Person must inspect the hot work area as often as necessary. If the Shipyard Competent Person discovers a change that could adversely alter safe conditions (such as a missing fire watch, ventilation failure, piping system leak, or hazardous materials spill), work must be stopped. Work may not be resumed until the affected space is visually inspected and re-evaluated (by a Marine Chemist, if a marine chemist certificate was issued) to meet requirements. [29 CFR 1915.15(f)]

Requirements and Example Solutions

Examples of items that can change conditions include:

- Temperature changes: increased or decreased temperatures affect flammable and toxic vapor levels.

- Type of work in tank: leaking torches, use of cleaning solvents, and removal of tank residue ("mucking out") may alter atmosphere.

- Unattended tanks or spaces: if a period of time has elapsed, it is recommended that spaces be retested before re-entry and continuation of work. [29 CFR 1915 Subpart A and Subpart B]

- Ballasting or trimming: changing the position of the vessel could release hazardous materials into a space or compartment.

- Ventilation changes: ventilation duct damage or fans not in use.

- SHAC recommends that tests before re-entry and continuation of work in unattended tanks and spaces should be conducted at the beginning of the shift and then at least every 24 hours between tests.

Potential Hazard

Fall hazards are a leading cause of shipyard fatalities. Shipyard employees are often required to work in dangerous environments that may include fall hazards. Accidents involving elevation equipment such as ladders, scaffolds, and aerial lifts are often serious, even fatal. Workers also risk falls from open deck edges.

Requirements and Example Solutions

Guarding of Deck Openings and Edges

- Openings and deck edges must be guarded. [29 CFR 1915.73]

- Flush manholes and other small openings must be guarded after opening. [29 CFR 1915.73(b)]

- During the installation of guards on large openings and deck edges, fall protection (harness with lanyard) must be used. [29 CFR 1915.73(d)]

- When floor plates or gratings (e.g. bilges, engine rooms, pump rooms, machinery spaces) are removed, the openings must be guarded or planked. [29 CFR 1915.73(f)]

Fall Protection for Scaffold Work

- Guardrails or other appropriate fall protection must be used when working on scaffolds 5 feet above surfaces. [29 CFR 1915.71(j)]

- During the installation of guards on scaffolds, fall protection must be used. [29 CFR 1915.73(d)]

- SHAC recommends that personal fall protection including lanyards and harnesses be used and secured during installation of guardrails and erection and dismantling of scaffolds.

Potential Hazard

Workers performing hot work operations are exposed to toxic gases and metal fumes (such as nitrogen oxides, zinc, or iron oxide fumes) that may cause occupational illnesses.

Requirements and Example Solutions

Ventilation removes or dilutes metal fumes and gases generated by hot work. The following ventilation requirements must be met:

- Replace withdrawn air with clean respirable (breathable) air. [29 CFR 1915.51(b)(1)(v)]

- Discharge contaminated air away from the source of the intake air. [29 CFR 1915.51(b)(1)(iv)]

- Mechanically ventilate toxic metal fumes, including: zinc, lead, cadmium, chromium, beryllium, mercury, nickel, arsenic, and copper. [29 CFR 1915.51(d)]

- Note: The presence of beryllium requires local mechanical exhaust ventilation and airline respirators. [29 CFR 1915.51(d)(1)(iv)]

- Adjust local exhaust ventilation on an ongoing basis. [29 CFR 1915.51(b)(1)(iii)]

- Warning: Do not use oxygen for ventilation or cleaning (blow-off). [29 CFR 1915.51(b)(1)(vi)]

Potential Hazard

Workers performing hot work in enclosed spaces are exposed to the risk of fires from ignition of flammable or combustible materials in the space and from leaks of flammable gas into the space from hot work equipment.

Requirements and Example Solutions

Fires caused by hot work in enclosed spaces can be prevented with the following precautions:

- Performing hot work in a designated area, or with fire hazards removed or covered. [29 CFR 1915.503(a)]

- Assigned additional personnel (fire watch) to guard against fire while hot work is being performed. [29 CFR 1915.504(b) and (c)] See Fire Protection: Fire Watches page.

- Not placing gas manifolds in enclosed or confined spaces. [29 CFR 1915.55(e)(2)]

- Not placing gas manifolds in enclosed or confined spaces. [29 CFR 1915.55(e)(2)]

- For additional requirements, see the Fire Protection chapter.

Note: When hot work is being performed, it is the employers' responsibility to ensure that precautions are taken in adjacent spaces. [29 CFR 1915.503(a)(2)]

Potential Hazard

Injury and illness may be caused by hot work (such as welding fumes, UV light, sparks, noise, skin injury, etc.).

Requirements and Example Solutions

Personal protective equipment is used during hot work to protect workers. A PPE program consists of the following:

- A PPE Hazard Assessment for all work activity [29 CFR 1915.152(b)]

- Worker training [29 CFR 1915.152(e)]

- Appropriate PPE use [29 CFR 1915.152(a)]

For more specific information, see PPE Selection: Hot Work.