Shipyard Employment eTool

Surface Preparation » Chemical Removers

Chemical paint strippers and removers used for surface preparation include corrosive acids, (e.g., hydrochloric and phosphoric), alkalis (e.g., sodium hydroxide/lye), chlorinated hydrocarbons (e.g., trichloroethane) and carcinogens (e.g., methylene chloride). These chemicals may present severe eye, skin and respiratory exposure hazards.

Paint strippers and removers potentially expose workers to:

Potential Hazards

Fire and explosions may be caused by:

- Flammable and combustible cleaning solvents such as Methyl Ethyl Ketone (MEK), mineral spirits, and diesel fuel/oil.

- Liquids with high flash points (greater than 100 F) may present a fire or explosion hazard when applied as a fine mist.

- Airborne particulate or dust.

- Hydrogen gas generated during cleaning processes.

- Reactive cargos such as iron-ore, fertilizer, or incompatible chemicals.

- Painting. See Painting and Other Coating Operations [29 CFR 1915.35].

Requirements and Example Solutions

- Hot work must not be performed in the space and/or adjacent spaces when flammable or combustible cleaning solvents are being used. [29 CFR 1915 Subpart P]

- Rags soaked with solvents must be placed in covered metal containers. [29 CFR 1915.36(a)(3)]

- No smoking or open flames. [29 CFR 1915.36(a)(1)]

- Arcing and sparking equipment and tools must not be used. [29 CFR 1915.36(a)(1)]

- Equipment that may generate static electricity (e.g. ventilation systems) must be grounded/bonded. [29 CFR 1915.13(b)(11)].

- Explosion-proof lights must be used. [29 CFR 1915.36(a)(4) and 29 CFR 1915.13(b)(9)]

- Adequate ventilation must be maintained (less than 10% of lower explosive limit (LEL)). [29 CFR 1915.13(b)(3) and 29 CFR 1915.36(a)(2)]

- Frequent tests shall be required during mixing and spill clean-up to determine if air concentrations are below 10% of the LEL. [29 CFR 1915.15(f) and 29 CFR 1915.36(a)(2)]

- The Shipyard Competent Person (SCP) must test the exhaust location to ensure that exhausted vapors do not accumulate to hazardous levels. [29 CFR 1915.13(b)(7), (b)(8), (b)(11), and (b)(12)]

- Suitable fire fighting equipment must be immediately available. [29 CFR 1915.36(a)(6), and 29 CFR 1915 Subpart P]

- Personnel using fire fighting equipment must be instructed on possible fire hazards and how to use the equipment. [29 CFR 1915 Subpart P]

- Spills of solvents must be cleaned up immediately. [29 CFR 1915.13(b)(5)]

Potential Hazard

Toxic vapors or corrosive mists produced by chemical paint and preservative removers may present significant health hazards including oxygen-deficient atmospheres. When used in confined or enclosed spaces these agents produce vapors that are often heavier than air. This can cause displacement of air, reducing oxygen levels, which may be fatal.

Note: Paint strippers often contain methylene chloride, which has additional requirements.

Requirements and Example Solutions

- Ensure adequate ventilation to maintain concentrations below the PEL. [29 CFR 1915.32(a)(2)]

- The Shipyard Competent Person (SCP) may require continual monitoring to determine air concentrations are within the PELs and below IDLH levels. If they are not, additional engineering controls (e.g., ventilation), administrative controls or PPE (e.g. respirators) must be used. [29 CFR 1915.32(a)(3)]

- Airline respirators may be necessary if ventilation is not adequate.

- Respirators must comply with 29 CFR 1915.154. [29 CFR 1910.134]

Additional Information

- Hazard Communication Guidelines for Compliance. OSHA Publication 3111 , (2000).

- Hazard Communication. OSHA Safety and Health Topics Page.

Potential Hazards

Toxic and corrosive paint strippers and removers can harm employees eyes and/or skin.

- Organ damage through skin or eye absorption.

- Skin or eye burns and irritation.

- Ingestion of contaminated food.

Requirements and Example Solutions

- Appropriate PPE must be used.

- Solvents spills must be cleaned up immediately.

- [29 CFR 1915.13(b)(5)]

- Washing facilities must be available.

- Workers must be trained in accordance with the Hazard Communication Standard. [29 CFR 1915.1200]

Additional Information

- Hazard Communication Guidelines for Compliance. OSHA Publication 3111 , (2000).

- Hazard Communication. OSHA Safety and Health Topics Page.

- Fixed or portable eye wash stations/safety showers should meet ANSI Z358.1-1998: Emergency Eye Wash and Shower Equipment.

Potential Hazards

When working in confined or enclosed spaces workers may become trapped and unable to exit due to:

- Improperly located equipment.

- Ventilation ducts and hoses running through the opening.

Requirements and Example Solutions

- When employees work in confined spaces with limited access, the access must not be blocked or impeded by ventilation ducts, hoses or other equipment. [29 CFR 1915.76(b)(2)]

- More than one means of access must be provided where practical. [29 CFR 1915.76(b)(1)]

- Additional openings should be provided for ducts, hoses, and other equipment.

Potential Hazards

Workers performing surface preparation are exposed to slick conditions and tripping hazards.

- Slipping and falling on oily decks.

- Tripping over equipment, hoses, and vessel structures.

Requirements and Example Solutions

- Spills must be cleaned up immediately. [29 CFR 1915.13(b)(5) and 29 CFR 1915.81]

- Visual Inspection. See Confined or Enclosed Spaces and Other Dangerous Atmospheres.

- Illumination. See General Working Conditions.

- Housekeeping. [29 CFR 1915.81]

Potential Hazards

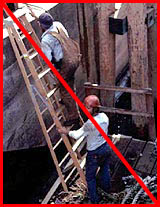

Fall hazards are a leading cause of shipyard fatalities. Shipyard employees are often required to work in dangerous environments that may include fall hazards. Accidents involving elevation equipment such as ladders and scaffolds are often serious, even fatal.

- Falls from ladders.

- Falls from scaffolds.

- Falls from open deck edges.

- Falls into open holes.

Requirements and Example Solutions

Guarding of Deck Openings and Edges

- Deck openings and edges must be guarded. [29 CFR 1915.73]

- Flush manholes and other small openings must be guarded after opening. [29 CFR 1915.73(b)]

- During the installation of guards on large openings and deck edges, fall protection (e.g., harness with lanyard) must be used. [29 CFR 1915.73(d)]

- When floor plates or gratings (e.g., bilges, engine rooms, pump rooms, machinery spaces) are removed, the openings must be guarded or planked. [29 CFR 1915.73(f)]

- Maritime Labor/Industry recommends that personal fall protection including lanyards and harnesses be used and secured during installation of guardrails.

Potential Hazards

Environmental hazards include temperature, humidity, and air movement within the work area. A combination of PPE use, heat producing equipment, work activity, and environmental conditions can cause temperature related illnesses.

Heat related illnesses include:

- Heat Stress

- Heat Stroke

- Heat Cramps

- Dehydration

Cold related illnesses include:

- Hypothermia

- Frost Bite

Additional Resources

- OSHA Technical Manual (OTM). OSHA Directive TED 01-00-015 [TED 1-0.15A], (January 20, 1999). Identifies heat stress as part of the evaluation process in the following:

- Heat Stress. Contains useful sections on the signs and symptoms of heat stress, sampling methods, control suggestions, and guidelines for investigating heat stress in the workplace.

- Heat Stress. OSHA Safety and Health Topics Page.

- Thermal Stress. ACGIH TLV Booklet.

Example Solutions

The following are recommended for heat related illnesses:

- Drink plenty of fluids.

- Take frequent breaks.

- Use a cooling vest.

- Take breaks in shaded or cooled areas.

- Use ventilation.

- Reduce the inner temperature of work spaces by using water sprinklers on outside metal surfaces.

- Conduct awareness training.

It is recommended that the following be implemented to prevent cold related illnesses:

- Wear appropriate insulated PPE.

- Use warming areas for breaks.

- Conduct awareness training.

Potential Hazards

The use of high pressure equipment may expose the operator as well as bystanders to the following hazards:

- Contact with high-pressure steam, water, or air streams from cleaning equipment.

- Contact by uncontrolled high-pressure hoses.

- Contact with steam, water, or air leaks from high-pressure equipment.

Injuries associated with these hazards include:

- Loss of body parts (e.g., fingers, hands, etc.)

- Lacerations

- Burns

- Loss of sight

Requirements and Example Solutions

- Steam guns must be insulated to prevent heat burns to the operator. [29 CFR 1915.33(e)]

- Appropriate PPE must be used. [29 CFR 1915.152]

- Access to the area should be controlled.

- Hoses and connections should be inspected prior to use.

Potential Hazards

Employees who work with or around electrical equipment in wet or damp locations have an increased risk of getting shocked or electrocuted due to:

- Faulty electrical connection in power tools.

- Open lighting parts.

- Broken insulation on power cords.

Requirements and Example Solutions

- Portable electrical tools must be grounded or double insulated. [29 CFR 1915.132(a)]

- Temporary lighting must be grounded. [29 CFR 1915.82(b)(8)]

- Power and lighting cables must be inspected by a person competent to evaluate electrical hazards. (Note: This is not the Shipyard Competent Person). [29 CFR 1915.36(a)(5)]

- All electrical tools or equipment should undergo a visual inspection prior to use.

- All portable electric hand tools and temporary lighting systems should utilize Ground Fault Circuit Interrupters (GFCI).

- Electrical tools and equipment should correspond with the requirements of the job.

- Electrical equipment and tools should be used with proper circuit protection for the voltage and amperage used.

- Only qualified electricians should attempt repair of electrical tools and equipment in use.

- A Ground Assurance Program should be in place for all electrical tools and equipment used including:

- Records of tools inspected and repaired.

- Records of electrical boxes inspected and repaired.

- Records of electrical extension cords inspected and repaired.

- Recall of records of the above.

- The requirements of the Ground Assurance Program should be performed on a regular basis.