Shipyard Employment eTool

Cleaning and Other Cold Work >> Cleaning Preparation

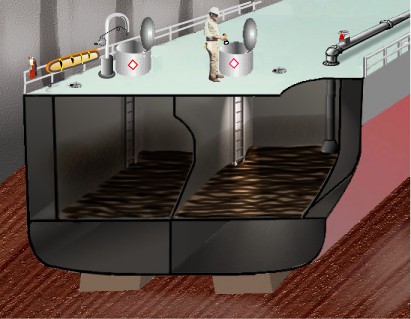

As shipbuilding progresses, confined and enclosed spaces are created. When these spaces require cleaning, a Shipyard Competent Person (SCP) must conduct atmospheric testing and a visual inspection of the space. [See Confined or Enclosed Spaces and Other Dangerous Atmospheres] After the atmospheric testing and visual inspection, workers can then prepare the space for cleaning. The following must be performed:

If the space to be entered has previously contained liquids or gases (such as materials from pressure testing), the following are also necessary before performing cold work:

Preparation for cleaning and cold work also includes coordinating the necessary personnel, equipment, and materials required for Cleaning Operations.

Note: Confined space entry is one of the leading hazards associated with barge cleaning. Review the Shipbuilding: Confined or Enclosed Spaces and Other Dangerous Atmospheres chapter for information on how to protect workers from this hazard.

Potential Hazard

Residues, such as fuels and lube oils, often remain in spaces following systems testing during ship building.

- Residues may be toxic or flammable/combustible (for example, fuel). These residues can cause illness, fire, or explosion.

Requirements and Example Solution

- Liquid residues of hazardous materials must be removed from work spaces as thoroughly as possible before employees begin cleaning operations. [29 CFR 1915.13(b)(1)]

Potential Hazard

Piping and pumping systems that enter the space may contain residual liquids or gases. These materials may be released or inadvertently pumped into the space, exposing workers to safety and health hazards.

Requirements and Example Solutions

- Pipes and pumping systems entering the work space must be disconnected, blanked off, and secured by a positive method, if they are possibly carrying hazardous materials. [29 CFR 1915.15(a)]

- Pumps within the system must be secured (for example, blanked or disabled). [29 CFR 1915.15(a)]

Potential Hazards

- Workers entering a space containing flammable, combustible, toxic, corrosive or irritant vapors, mists, or gases are at risk of fire and explosion, as well as health hazards.

- Cleaning operations may also generate concentrations of flammable, combustible, toxic, corrosive or irritant vapors, mists, or gases through interaction of cleaning agents, or reactions of cleaning agents with residues.

Requirements and Example Solutions

- Testing must be conducted by a Shipyard Competent Person (SCP) to determine the concentration of flammable, combustible, toxic, corrosive, or irritant vapors within the space.[29 CFR 1915.13(b)(2)]

- Continuous ventilation must be provided at volumes and flow rates sufficient to ensure that the concentrations of:

- Flammable vapor is maintained below 10% of the lower explosive limit. [29 CFR 1915.13(b)(3)(i)]

- Toxic, corrosive, or irritant vapors are maintained within the permissible exposure limits and below mmediately dangerous to life or health (IDLH). [29 CFR 1915.13(b)(3)(ii)]

- When ship repair operations result in flammable/combustible atmospheres:

- Air-moving equipment and its component parts, including duct work capable of generating a static electric discharge of sufficient energy to create a source of ignition must be electrically bonded to the structure of a vessel or vessel section, or in the case of landside spaces, grounded to prevent an electric discharge in the space. [29 CFR 1915.13(b)(11)]

- Fans must have non-sparking blades and portable air ducts shall be of non-sparking materials. [29 CFR 1915.13(b)(12)]

Potential Hazard

Without adequate warnings, workers may enter unsafe spaces and be exposed to safety and health hazards. In addition, workers that are unable to read or understand signs are not protected.

Requirements and Example Solutions

- The shipyard competent person report and/or certified marine chemist certificate must be posted in the immediate vicinity of the effected operation while work is in progress. [29 CFR 1915.7(d)(2) and 29 CFR 1915.14(a)(2)]

- Posted signs or labels must be presented in a manner (languages or symbols) that can be perceived and understood by every worker. [29 CFR 1915.16(a)] See Figure 5.

- A warning sign or label may be posted at the means of access if the entire work area has been tested. [29 CFR 1915.16(b)]

- If the space contains an oxygen-deficient or -enriched atmospheres, the space must be labeled "Not Safe for Workers" and not entered until the oxygen content is between 19.5% and 22%. [29 CFR 1915.12(a)(2)]

- If the concentration of flammable vapors or gases in the space is equal to or greater than 10 percent of the lower explosive limit (LEL) the space must be labeled "Not Safe for Workers" and not entered until the concentration of flammable vapors is maintained below 10% of the LEL. [29 CFR 1915.12(b)(2)]

- If the space contains an air concentration of a material which exceeds a Part 1915 Subpart Z permissible exposure limit (PEL) or is IDLH, the space shall be labeled "Not Safe for Workers." [29 CFR 1915.12(c)(2)]

- Signs prohibiting sources of ignition within or near spaces that previously contained flammable or combustible liquids or gases must be posted at the entrance to those spaces, in adjacent spaces, and in the open area adjacent to those spaces. [29 CFR 1915.13(b)(10)]

Potential Hazards

- Inadequate illumination in a space can lead to injuries from slips, trips, and falls.

- Workers entering inadequately illuminated spaces may become disoriented and fail to find the exit. This prevents the worker from safely exiting the space.

- Inadequate illumination can prevent workers from safely performing tasks.

Requirements and Example Solutions

- All means of access and walkways leading to work areas as well as working areas themselves must be adequately illuminated. [29 CFR 1915.82(a)(1)]

- Temporary lights must meet the requirements of 29 CFR 1915.82(b) and (c).

- Where temporary lighting from sources outside the vessel is the only means of illumination, portable emergency lighting equipment must be available to provide illumination for employees to move about safely. [29 CFR 1915.82(c)(2)]

- Employees must not be permitted to enter dark spaces without a suitable portable or emergency light. [29 CFR 1915.82(c)(1)]

- The use of matches and open-flame lights is prohibited.[29 CFR 1915.82(a)(5)]

- Explosion-proof, self-contained temporary or portable lights are required in any area that the atmosphere is determined to contain a concentration of flammable vapors that are at or above 10 percent of the lower explosive limit (LEL) (29 CFR 1915, subparts B and C) [29 CFR 1915.82(d)]

- In spaces that have previously contained bulk quantities of flammable/combustible liquids or gas (such as after testing lube or fuel systems):

- Only explosion proof, self-contained portable lamps (for example, explosion-proof flashlight) or other electric equipment approved for hazardous locations by a National Recognized Testing Laboratory (NRTL), shall be used until the space is deemed "Safe for Workers". [29 CFR 1915.13(b)(9)] See Figure 7.

Additional Resources

- A11.1: Illumination. ANSI Standard.

Potential Hazard

- Toxic, corrosive, irritant, or high pressure/temperature cleaning agents and their application equipment, may put the safety and health of workers at risk.

Requirements and Example Solutions

- A hazard assessment must be made to determine the appropriate PPE. [29 CFR 1915.152(b)]

-

Also see the PPE requirements for specific cleaning operation hazards that may be encountered:

Additional Resources

- See General Requirements: PPE for information on general PPE requirements and example specific cleaning operation PPE.