Transitioning to Safer Chemicals:

A Toolkit for Employers and Workers

Step 2: Examine Current Chemical Use

To identify targets for informed substitution, you need to know how you use chemicals in your workplace and the hazards associated with each of these chemicals. This step will help you examine your current chemical use.

For each chemical, consider:

- Where is the chemical being used?

- What function does the chemical perform?

- Is the chemical necessary in the process or product? Could the chemical be eliminated without adversely affecting product or process performance?

- What are the hazards associated with the chemical and how could its use harm workers?

- How are workers potentially exposed to the chemical (i.e., during manufacturing of the chemical or product, when using a product containing chemicals, when applying the chemical in a service industry, or during chemical disposal)?

To identify priorities, consider:

- What hazards should be eliminated or reduced first?

- What uses of chemicals are of greatest concern?

- What potential chemical exposures to workers are of greatest concern?

- Could a chemical or process change help improve workplace safety and health?

- Are the identified priorities consistent with the work plan for transitioning to safer chemicals?

First, you should work with your team to develop an up-to-date inventory of all the chemicals used in your workplace, including chemicals used during production, performing service tasks, and during cleaning and maintenance operations. This should include information about how the chemical is made, handled, stored, disposed, or transported. You should also describe the function the chemical performs, as well as the physical form of the chemical, the frequency and duration of the chemical use, and the quantity of the chemical used. It is important to understand whether the use of the chemical is actually necessary in your operation. The safety data sheets (SDSs) required for hazardous chemicals under OSHA's Hazard Communication standard (29 CFR 1910.1200(g)(1)) can provide a helpful starting point for your inventory; however, ensure your inventory is updated so that it includes all uses of all chemicals in your workplace, and ensure your supplier has provided you with a manufacturer’s SDS for each chemical. Incomplete SDSs or SDSs that do not include information about ingredients below a certain concentration are good examples of why all chemicals, not just those classified as "hazardous," should be inventoried in this step. The chemical use inventory can be as simple as a list or spreadsheet or as sophisticated as a process flow diagram. A process flow diagram graphically illustrates the chemical inputs, products, and non-product output streams for a particular manufacturing process and may point out upstream changes that could help reduce or eliminate the use of hazardous chemicals. While it may be easier to compile information about chemicals used in the processes in your workplace, it is also important to know which chemicals are contained in products used by workers and the hazards associated with them. Workers in non-manufacturing industries – such as cleaners, plumbers, floor installers, and construction workers –encounter chemicals in such products on a regular basis.

Next, you should identify the hazards associated with the chemicals used in your workplace. This should be a rapid evaluation of the hazards using existing resources, rather than an in-depth assessment requiring interpretation of toxicological test results or other scientific literature. Cross-referencing chemicals in your workplace to those on restricted substances lists and reviewing the hazard categories listed on safety data sheets can help you identify the most hazardous chemicals. Other chemical databases, such as ChemHAT and RISCTOX can help you quickly identify the hazards associated with chemicals you use in the workplace.

Key Resource

Chemical Hazard and Alternatives Toolbox (ChemHAT)

ChemHAT helps workers and employers understand whether a chemical can impact their health and whether safer alternatives exist.

The chemical information provided by ChemHAT allows you to rapidly understand the types of health effects related to a chemical and the strength of those effects. This information can help you examine your chemical use and identify which hazards you should eliminate or reduce first. ChemHAT also provides information on existing case studies of safer alternatives. This information can help you quickly understand where the potential for substitution exists and what alternatives you should consider evaluating further.

Key Resource

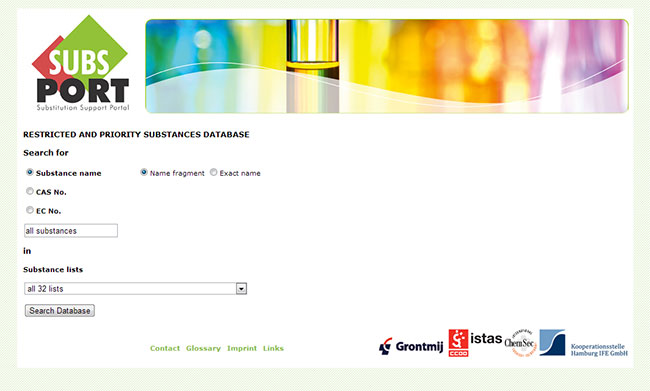

Restricted and Priority Substance Database

Lists of restricted and priority substances can provide a good starting point for identifying the most hazardous chemicals in your workplace. These lists generally include chemicals that are currently restricted by a government body anywhere in the world, as well as chemicals of concern that are not yet regulated. Through SUBSPORT's Restricted and Priority Substance Database, you can simultaneously search 32 lists of substances that are legally or voluntarily restricted or are recommended for restriction due to their hazards. The database includes lists from international agreements, EU regulatory lists, governmental lists, non-governmental organization and trade union lists, and internal company lists.

Key Resource

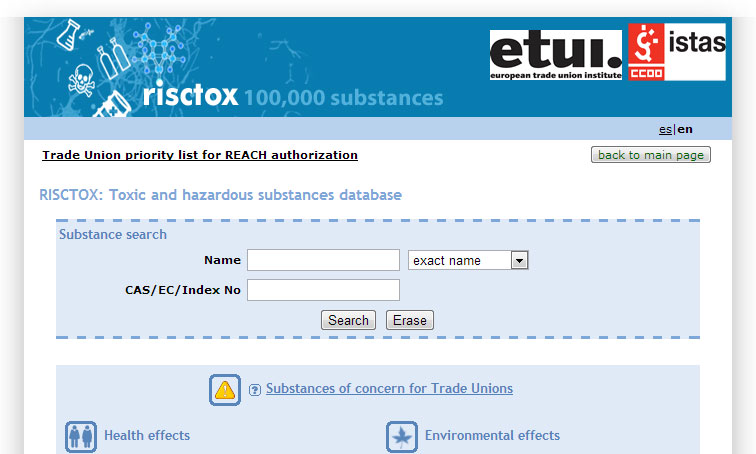

RISCTOX

Databases that compile multiple sources of chemical information can help you quickly understand the hazards associated with the chemicals used in your workplace. RISCTOX is a database of over 100,000 chemical substances that provides clear, organized, and concise information about health and environmental risks. The database includes data on a substances’: classification by the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), specific health risks, specific environmental risks, and environmental and health-related regulations.

While it is important to consider transitioning to safer alternatives for each of the hazardous chemicals used in your workplace, you do not have to pursue substitution activities for every chemical immediately. Instead, you should work with your team to identify priorities to maximize the use of limited resources. Chemicals can be prioritized based on various criteria, including, but not limited to: hazard, exposure, risk, regulation potential, established company policies, interests of relevant stakeholders, and substitution potential. OSHA 300 logs may also provide helpful information about what chemical uses and exposures are of greatest concern in your workplace. Setting these priorities could reflect the larger goals in your work plan for transitioning to safer chemicals or help you further refine your work plan.

Key Resource

European Commission's Prioritization Matrix

The European Commission’s Guidance on Minimizing Chemical Risk to Workers’ Health and Safety Through Substitution provides a risk matrix tool that can be used for prioritization. The tool combines a qualitative evaluation of hazard and exposure potential to identify chemicals that could be good targets for substitution efforts. The matrix uses hazard categories found on a Safety Data Sheet to rank the hazard level of the chemical from1 (low hazard) to 5 (very high hazard). The matrix uses information about where, how often, and in what way the chemical is used to rank exposure potential from 1 (low exposure) to 5 (very high exposure) with regards to working/process conditions, physical properties affecting exposure, frequency or duration of use, quantity used, and accident potential. Combining the qualitative hazard and exposure potential scores allows you to identify chemicals with the highest risk and greatest potential for substitution.

Creating Chemical Inventories

Massachusetts Department of Environmental Protection. Toxics Use Reduction Planning and Plan Update Guidance. *(PDF) This guidance describes and provides support for the toxics use reduction planning process, presents best management practices, and shares examples of actual toxics use reduction successes.

New Jersey Department of Environmental Protection. Industrial Pollution Prevention Planning. *(PDF) This report identifies twelve steps that can help firms identify and achieve pollution prevention opportunities.

NEWMOA. Energy and Materials Flow and Cost Tracker (EMFACT). This software tool helps companies systematically track materials and energy use; releases, discharges, and wastes; and associated costs in ways that can create value for their business.

Obtaining Product Chemical Information

Green Chemistry and Commerce Council. Meeting Customers’ Needs for Chemical Data: A Guidance Document for Suppliers. *(PDF) This document outlines resources that can assist suppliers in collecting and providing chemical information to their customers.

Assessing Chemical Hazard

ChemSec. SIN (Substitute It Now!) List. This database contains 626 chemicals identified as Substances of Very High Concern based on the criteria established by the EU chemical regulation, REACH.

Dutch Ministry of Housing, Spatial Planning and Environment. Quick Scan. *(PDF) This is a screening method that uses existing data, criteria and decision-making rules to evaluate substances and place them into categories of concern based on hazard.

European Chemicals Agency (ECHA). Classification and Labeling Inventory Database. This database contains classification and labeling information on REACH notified and registered substances received from manufacturers and importers, as well as the list of EU harmonized hazard classifications.

Healthy Building Network. Pharos. This resource includes a chemical and material library containing over 20,000 substances screened against over 40 authoritative hazard and warning lists. The library identifies health hazards that may come directly from exposure to a substance or from chemicals used or created in its production.

Interstate Chemicals Clearinghouse (IC2). State Priority Chemicals Resource. This database contains lists of priority chemicals developed under various state laws.

ISTAS. RiscTox. This database provides information about health and environmental risks for over 100,000 chemical agents.

IUE-CWA and BlueGreen Alliance. ChemHAT—Chemical Hazard and Alternatives Toolbox. This database provides information on chemical hazards, uses, exposures, and safer alternatives.

KEMI--Swedish Chemicals Agency. PRIO. This is a web-based tool intended to facilitate the assessment of health and environmental risks of chemicals so that risk reduction opportunities can be identified and prioritized.

Ministry of Social Affairs and Employment of Netherlands. Stoffenmanager. This is a tool for small and medium-sized enterprises to prioritize their health risks to dangerous substances and to determine effective control measures.

SUBSPORT. Restricted and Priority Substances Database. This database contains 32 lists of substances that are legally or voluntarily restricted or are recommended for restriction due to their hazards.

U.S. Environmental Protection Agency. ChemView. This web tool displays key health and safety data on chemicals and provides streamlined access to EPA assessments, hazard characterizations, and information on safer chemical ingredients.

National Library of Medicine. National Center for Biotechnology Information. PubChem: National Library of Medicine. This database provides information on toxicology, hazardous chemicals, environmental health, and toxic releases.