Evacuation Plans and Procedures eTool

Emergency Standards » Fixed Extinguishing Systems

Fixed fire extinguishing/suppression systems are commonly used to protect areas containing valuable or critical equipment such as data processing rooms, telecommunication switches, and process control rooms. Their main function is to quickly extinguish a developing fire and alert occupants before extensive damage occurs by filling the protected area with a gas or chemical extinguishing agent.

In this section we will review the employer's responsibilities for operating, testing, and maintaining fixed extinguishing systems that are installed to meet a particular OSHA standard, 29 CFR 1910.160(a)(1), or where its extinguishing agent may expose employees to possible injury, death, or adverse health effects. [29 CFR 1910.160(a)(2)] This section does not apply to automatic sprinkler systems or to systems installed to protect areas where there is no potential for employee exposure. [29 CFR 1910.159]

This section will help you understand your requirements under the fixed extinguishing system standard by addressing the following issues:

- Does the "Fixed Extinguishing System" standard apply to me?

- System design and application

- Operation, maintenance, and testing

- Total flooding applications

For further assistance, consult the following National Fire Protection (NFPA) standards:

- NFPA 12, Standard on Carbon Dioxide Extinguishing Systems

- NFPA 12A, Standard on Halon 1301 Fire Extinguishing Systems

- NFPA 17, Standard for Dry Chemical Extinguishing Systems

- NFPA 17A, Standard for Wet Chemical Extinguishing Systems

- NFPA 750, Standard on Water Mist Fire Protection Systems

- NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems

OSHA's fixed extinguishing systems, general standard applies to all employers who have a fixed extinguishing system installed to meet a particular OSHA standard, with the exception of automatic sprinkler systems that are covered by 29 CFR 1910.159. 29 CFR 1910.160 contains specific provisions for any fixed system, regardless of why it was installed, that may expose employees to possible injury, death, or adverse health consequences caused by the extinguishing agent. These systems are only subject to the requirements of 29 CFR 1910.160(b)(4) through 29 CFR 1910.160(b)(7) and 29 CFR 1910.160(c) of this standard.

OSHA's "Fire Extinguishing System" Standard includes a general standard applicable all fixed extinguishing systems, and three specific standards, applicable to the type of extinguishing agent used:

- 29 CFR 1910.160, Fixed extinguishing systems, general

- 1910.160(a), Scope and application

- 1910.160(b), General requirements

- 29 CFR 1910.161, Fixed extinguishing systems, dry chemical

- 1910.161(a), Scope and application

- 1910.161(b), General requirements

- 29 CFR 1910.162, Fixed extinguishing systems, gaseous agent

- 1910.162(a), Scope and application

- 1910.162(b), General requirements

- 29 CFR 1910.163, Fixed extinguishing systems, water spray and foam

- 1910.163(a), Scope and application

- 1910.163(b), General requirements

NOTE: Systems installed to protect areas where there is no potential for employee exposure to the extinguishing agent are exempted from the requirements of this standard.

A fire extinguishing systems is an engineered set of components that work together to quickly detect a fire, alert occupants, and extinguish the fire before extensive damage can occur. All system components must be:

- Designed and approved for use on the specific fire hazards they are expected to control or extinguish. [29 CFR 1910.160(b)(1)]

- Protected against corrosion or either made or coated with a non-corrosive material if it may be exposed to a corrosive environment. [29 CFR 1910.160(b)(12)]

- Designed for the climate and temperature extremes to which they will be exposed. [29 CFR 1910.160(b)(14)]

Typical elements and components include:

-

Discharge Nozzles

Discharge nozzles are used to disperse the extinguishing agent into the protected area. -

Piping

The piping system is used to transport the extinguishing agent (carbon dioxide, halon, argon, etc) from its storage container to the discharge nozzle. -

Control Panel

The control panel integrates all devices and displays their operational status and condition. -

Discharge or Warning Alarm(s)

Electronic devices that provide an audible or visual alarm when detected. -

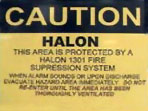

Hazard Warning or Caution Signs

Hazard warning signs must be posted at the entrance to, and inside, areas protected by fixed extinguishing systems. -

Automatic Fire Detection Device(s)

A device that detects fire and causes an alarm signal to be generated. -

Manual Discharge Station(s)

A device that provides a way to manually discharge the fire extinguishing system. -

Storage Container(s) & Extinguishing Agent

The storage system discharges agent into the piping and through the discharge nozzles when activated by a manual or automatic device.

NOTE: Use your mouse to explore the picture above. Hover over any number to go to that component's requirements.

Discharge Nozzles:

A discharge nozzle is a device designed to release the extinguishing agent at a specific rate and pattern to quickly extinguish a fire. Discharge nozzles must be suitable for the fire it is intended to extinguish. [29 CFR 1910.160(b)(1)]

The nozzle pictured is designed for total flooding applications. Its bell shape and multiple small discharge openings will create a widely dispersed and diffused discharge pattern to quickly flood an enclosed area with an extinguishing agent. This type of nozzle is common in paint spray booths, flammable liquid storage rooms or other similar areas.

Nozzles designed for local application usually consist of a cylindrical body with a straight unobstructed center opening. This type of nozzle produces a small discharge pattern that directs the agent toward a local application such as paint dip tanks, quench tanks or areas where a flammable liquid spill may occur.

Piping:

The piping network is designed to properly distribute the extinguishing agent to the protected areas. All fire protection systems must have pipes and fittings that are suitable for the expected temperature extremes with good corrosion resistance properties.

Control Panel:

The control panel monitors and integrates all components together and controls the audible and visual alarms and discharge functions. When an automatic or manual device is activated it sends a signal to the control panel where, depending on the type of system and hazards, can be programmed to:

- Activate a pre-discharge alarm.

- Initiate agent release.

- Shutdown ventilation systems.

- Shutdown machinery or equipment.

- Activate visual and audible fire alarms.

- Notify emergency response personnel.

Discharge Alarm or Signaling Devices:

Each area protected by a fixed extinguishing system must have a distinctive alarm or signal which complies with 29 CFR 1910.165 to alert occupants that the system is discharging. These alarms must be able to be heard or seen above ambient noise or light levels, unless the discharge is immediately recognizable. [29 CFR 1910.160(b)(3)]

If the alarm or signaling device is used on a total flooding system, it must also:

- Alarm before the system discharges, to give employees sufficient time to safely exit the space. [29 CFR 1910.160(c)(3)]

- Be connected to an approved fire detection device that automatically activates the pre-discharge alarm prior to the system discharge. [29 CFR 1910.160(c)(4)]

- Be addressed in an emergency action plan in accordance with 29 CFR 1910.38 for each area that is protected.

NOTE: Areas protected by a total flooding system where employees cannot enter during or after the system's operation are exempt from the requirements of 29 CFR 1910.160(c) of this section. [29 CFR 1910.160(c)(2)]

Warning Signs and Safeguards

Warning signs must be posted to warn employees in advance about the hazards associated with the extinguishing agent. Hazard warning or caution signs must be posted at the entrance to and inside of areas protected by fixed extinguishing systems which use agents in concentrations known to be hazardous to employee safety and health. [29 CFR 1910.160(b)(5)]

Recommended guidelines for posting:

- To avoid confusion, keep hazard warning signs consistent by using standardized patterns, phrases, colors, shapes and pictures.

- Wording on signs should be concise, easy to read, and contain sufficient information that is easily understood.

- Warning signs must be in English and should also be posted in the native language spoken by the employees.

In addition to warning signs, the employer must also provide effective safeguards to warn employees when the atmosphere of a protected area remains hazardous to their safety or health as a result of a system discharged. [29 CFR 1910.160(b)(4)]

Automatic Fire Detectors:

Automatic detection devices sense the smoke, heat, or flames from a fire and initiate an alarm. All automatic detection equipment must be approved, installed and maintained in accordance with 29 CFR 1910.164.

Automatic detection devices used on a total flooding system must:

- Automatically activate the pre-discharge alarm before the system discharges to give employees time to safely exit from the protected area. [29 CFR 1910.160(c)(4)]

Note: Areas protected by a total flooding system where employees cannot enter during or after the system's operation are exempt from the requirements of 29 CFR 1910.160(c) of this section. [29 CFR 1910.160(c)(2)]

Manual Discharge Station:

A manual discharge station is a device usually mounted on a wall near the emergency exit(s) which will automatically sound an alarm and release the extinguishing agent. If your workplace is equipped with a fixed suppressant system, there must be at least one manual station for each protected area. [29 CFR 1910.160(b)(15)]

Pull Station Guidelines:

- Properly mark and/or label pull stations and other activation devices to indicate their function and the potential hazard to personnel. [29 CFR 1910.160(b)(16)]

- Pull stations must be clearly visible (not blocked or covered) and located near exits or escape routes.

- Post operating instructions at each station.

- Train employees to know when, where, and how to use pull stations.

- Determine, if possible, if someone is in the area and get them out before using a manual discharge station.

Extinguishing Agent Storage Containers:

Storage containers hold the extinguishing agent until it is needed and can be high or low pressure cylinders or tanks. These containers can be used to hold specialized fire suppression agents like carbon dioxide or halon to protect special work areas, such as computer rooms, chemical storage, or similar areas.

Storage Container Requirements:

- Check the weight and pressure of refillable containers at least semi-annually. Maintain the the container if it shows a loss in net content or weight of more than 5 percent, or a loss in pressure of more than 10 percent. [29 CFR 1910.160(b)(7)]

- Weigh factory charged non-refillable containers that have no means of pressure indication at least semiannually. Replace the container if it shows a loss in net content or weight of more than 5 percent. [29 CFR 1910.160(b)(8)]

- Record inspection and maintenance dates on the container, on a tag attached to the container or in a central location. Maintain a record of the last semi-annual check until the container is checked again or for the life of the container, whichever is less. [29 CFR 1910.160(b)(9)]

- Do not use chlorobromomethane or carbon tetrachloride as an extinguishing agent in an area where employees may be exposed. [29 CFR 1910.160(b)(11)]

Automatic fire suppression systems, particularly the total flooding variety, must be operated properly and regularly maintained and tested to guarantee worker safety and system effectiveness. To ensure your fire extinguishing system will perform as expected in the event of a fire, you are required to:

- Inspect each system annually, and operate and maintain them in a working condition, making sure they are always turned on, except during repairs or maintenance. [29 CFR 1910.160(b)(6)]

- Notify employees and establish measures to guarantee their safety if a fixed extinguishing system becomes inoperable. Fix any defects or impairments by trained personnel. [29 CFR 1910.160(b)(2)]

- Check the weight and pressure of refillable containers at least semiannually. If the container shows a loss in net content, weight, or pressure, it must be subjected to maintenance. [29 CFR 1910.160(b)(7)]

- Assure that factory charged non-refillable containers that have no means of pressure indication are weighed at least semiannually. Replace the container if it shows a loss in net weight. [29 CFR 1910.160(b)(8)]

- Assure that inspection and maintenance dates are recorded and kept until the container is checked again or for the life of the container, whichever is less. [29 CFR 1910.160(b)(9)]

- Train employees designated to inspect, maintain, operate, or repair fixed extinguishing systems. Review their training annually to keep them up-to-date. [29 CFR 1910.160(b)(10)]

- Train all employees with respect to the type of systems installed in the workplace, the hazards involved, proper activation in case of emergency, and the correct response to audible and visual pre-discharge alarms. Provide training for non-English speaking employees in languages understood by the affected employees and other individuals that may be exposed to the hazard.

- Provide and assure the use of personal protective equipment (PPE) for rescuing employees trapped in areas that have become hazardous due to an agent discharge. [29 CFR 1910.160(b)(17)]

Total Flooding Applications consist of protecting an enclosed space by flooding it with a gas, such as carbon dioxide or halon. This method is used to protect electrical equipment and other types of deep-seated smoldering fires that may re-ignite after the flame has been extinguished. Because these systems can create an oxygen deficit or toxic atmosphere they deserve special attention.

The following special provisions apply to all fixed suppression systems used for total flooding applications:

- Assure that employees are not exposed to toxic levels of gaseous agent or its decomposition products. [29 CFR 1910.162(b)(3)] The requirements of 29 CFR 1910.162(b)(2) and 29 CFR 1910.162(b)(4) through 29 CFR 1910.162(b)(6) apply only to total flooding applications.

- Maintain the designed concentration of gaseous agents until the fire has been extinguished or is under control except during overhaul. [29 CFR 1910.162(b)(2)]

- Assure that the designed extinguishing concentration is reached within 30 seconds of initial discharge except for Halon systems which must achieve design concentration within 10 seconds. [29 CFR 1910.162(b)(4)]

- Provide a distinctive pre-discharge employee alarm capable of being perceived above ambient light or noise levels when agent design concentrations exceed the maximum safe level for employee exposure.

- Provide a pre-discharge employee alarm for alerting employees before system discharge on Halon 1211 and carbon dioxide systems with a design concentration of 4 percent or greater and

-

Provide a pre-discharge employee alarm for Halon 1301 systems with a design concentration of 10 percent or greater.

The pre-discharge employee alarm shall provide employees time to safely exit the discharge area prior to system discharge.

- Do not use Halon 1301 in concentrations greater than 7 percent where egress from an area cannot be accomplished within one minute. [29 CFR 1910.162(b)(6)(i)]

- Do not use Halon 1301 in concentrations greater than 10 percent where egress from an area cannot be takes greater than 30 seconds but less than one minute. [29 CFR 1910.162(b)(6)(ii)]

- Use Halon 1301 concentrations greater than 10 percent only in areas not occupied by employees provided that any employee in the area can escape within 30 seconds. Assure that no unprotected employees enter the area during agent discharge.

- Provide an emergency action plan in accordance with 29 CFR 1910.38 to provide for the safe evacuation of employees from within each area protected by a total flooding system which provides agent concentrations exceeding the maximum safe levels set forth in 29 CFR 1910.162(b)(5) and 29 CFR 1910.162(b)(6). [29 CFR 1910.160(c)(1)]

- Systems installed in areas where employees cannot enter during or after the system's operation are exempt from the requirements of this section. [29 CFR 1910.160(c)(2)]

- Equip each area protected with a pre-discharge alarm that complies with 29 CFR 1910.165 that is capable of being perceived above light or noise levels, and which gives employees time to safely exit the area before discharge. [29 CFR 1910.160(c)(3)]

- Install and connect fire detection devices to a control system which sounds a pre-discharge alarm and automatically activates total flooding systems. [29 CFR 1910.160(c)(4)]

- Post signs in and at the entrance to areas protected by total flooding fire suppression systems which use agents that are a serious health hazard, such as carbon dioxide, Halon 1211, etc.

- Have personal protective equipment (such as 5-minute "escape packs") available and ready for rescuing employees trapped in areas that may become hazardous due to an agent discharge. [29 CFR 1910.160(b)(17)]

Safety and Health Hazards:

The Material Safety Data Sheet for each extinguishing agent should be available in the workplace. It is important that employees know the potential hazards of the extinguishing agents they may be exposed to and how to protect themselves. Additionally, employees who are likely to enter such areas should receive a basic level of instruction into the operating principles of the system to include alarms and related hazards, as well as evacuation procedures. The two most common extinguishing agents used for total flooding applications are carbon dioxide and halon.

Carbon Dioxide:

Carbon dioxide, under normal conditions, is a colorless, odorless, electrically nonconductive gas that is approximately 1.5 times heavier than air. It will not disturb live electrical components, is non-corrosive, and leaves no residue to clean up.

- Agents used for initial supply and replenishment shall be of the type approved for the system's application. Carbon dioxide obtained by dry ice conversion to liquid is not acceptable unless it is processed to remove excess water and oil. [29 CFR 1910.162(b)(1)]

Specific hazards include:

- Asphyxiation - Exposure to high concentrations of CO2 gas may create an oxygen-deficient atmosphere.

- Cold Temperature - Direct contact with the vaporizing liquid during discharge can cause frostbite burns to the skin.

- For further assistance, consult NFPA 12, Standard on Carbon Dioxide Extinguishing Systems.

Halon Systems:

Halon is a bromo freon that works by replacing oxygen, thus creating an oxygen-deficient atmosphere. This can be very dangerous to employees. The reaction products of halon on hot surfaces may result in the release of toxic substances and carcinogens. These areas should be clearly labeled as follows:

Specific halon hazards include:

- Asphyxiation - Exposure to high concentrations of halon can create an oxygen-deficient atmosphere.

- Cold Temperature - Direct contact with the vaporizing liquid during discharge can cause frostbite burns to the skin.

- Central Nervous System (CNS) - Inhaling high concentrations of halon gas can cause dizziness, tingling in extremities and, in severe cases, unconsciousness.

- Cardiovascular Effect - In some people, exposure to halon can cause an increased sensitivity of the heart to adrenaline resulting in irregular heartbeats and, in severe cases, heart attack.

- When halon is exposed to temperatures above 900 degrees F. it could break down and create high concentrations of toxic gases.

- For further assistance, consult NFPA 12A, Standard on Halon 1301 Fire Extinguishing Systems.