Evacuation Plans and Procedures eTool

Emergency Action Plan » Evacuation Elements

OSHA's Floorplan Examples

A disorganized evacuation can result in confusion, injury, and property damage. When developing your emergency action plan, it is important to determine the following:

- Conditions under which an evacuation would be necessary.

- Conditions under which it may be better to shelter-in-place.

- A clear chain of command and designation of the person in your business authorized to order an evacuation or shutdown.

- Specific evacuation procedures, including routes and exits.

- Specific evacuation procedures for high-rise buildings.

- Procedures for assisting visitors and employees to evacuate, particularly those with disabilities or who do not speak English.

- Designation of what, if any, employees will remain after the evacuation alarm to shut down critical operations or perform other duties before evacuating.

- A means of accounting for employees after an evacuation.

- Special equipment for employees.

- Appropriate respirators.

During development and implementation of your draft plan, think about all possible emergency situations and evaluate your workplace to see if it complies with OSHA's emergency standards.

A wide variety of emergencies both man-made and natural, may require a workplace to be evacuated. These emergencies include - fires, explosions, floods, earthquakes, hurricanes, tornadoes, toxic material releases, radiological and biological accidents, civil disturbances and workplace violence.

Employers will want their employees to respond differently to these different threats. For example, employers may want to have employees assemble in one area inside the workplace if threatened by a tornado or perhaps a chemical spill on an adjacent highway, but evacuate to an exterior location during a fire. Your plan must identify when and how employees are to respond to different types of emergencies. Ask yourself questions and brainstorm worst-case scenarios. What would happen if the storeroom caught fire, the river flooded, or a chemical release occurred in the shop?

The type of building you work in may be a factor in your decision. Most buildings are vulnerable to the effects of disasters such as tornadoes, earthquakes, floods, or explosions. The extent of the damage depends on the type of emergency and the building's construction. Modern factories and office buildings, for example, are framed in steel and are structurally more sound than neighborhood business premises may be. In a disaster such as a major earthquake or explosion, however, nearly every type of structure will be affected. Some buildings will collapse and others will be left with weakened floors and walls.

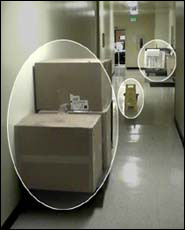

Most employers create maps from floor diagrams with arrows that designate the exit route assignments. These maps should include locations of exits, assembly points, and equipment (such as fire extinguishers, first aid kits, spill kits) that may be needed in an emergency. Exit routes should be:

- Clearly marked and well lit.

- Wide enough to accommodate the number of evacuating personnel.

- Unobstructed and clear of debris at all times.

- Unlikely to expose evacuating personnel to additional hazards.

- For more information on exit routes, required height and widths, door access and hinges, see Design and Construction Requirements for Exit Routes.

When preparing drawings that show evacuation routes and exits, post them prominently for all employees to see. See OSHA's Floorplan Diagram example and OSHA's Interactive Floorplan Demonstration.

Also, see Maintenance, Safeguards, and Operational Features for Exit Routes.

Many employers designate individuals as evacuation wardens to help move employees from danger to safe areas during an emergency. Generally, one warden for every 20 employees should be adequate, and the appropriate number of wardens should be available at all times during working hours.

Wardens may be responsible for checking offices, bathrooms, and other spaces before being the last person to exit an area. They might also be tasked with ensuring that fire doors are closed when exiting. All employees designated to assist in emergency evacuation procedures should be trained in the complete workplace layout and various alternative escape routes if the primary evacuation route becomes blocked. Employees designated to assist in emergencies should be made aware of employees with special needs (who may require extra assistance during an evacuation), how to use the buddy system, and any hazardous areas to avoid during an emergency evacuation.

Visitors also should be accounted for following an evacuation and may need additional assistance when exiting. Some employers have all visitors and contractors sign in when entering the workplace and use this list when accounting for all persons in the assembly area. The hosts and/or area wardens, if established, are often tasked with helping these individuals safely evacuate.

You also may find it beneficial to coordinate the action plan with other employers when several employers share the worksite, although OSHA standards do not specifically require this.

Certain equipment and processes must be shut down in stages or over time. In other instances it is not possible or practical for equipment or certain process to be shut down under certain emergency situations. This condition, which is not unusual for certain large manufacturers operating complex processes, is not typical of small enterprises that normally can turn off equipment or utilities if necessary and evacuate. However some small enterprises may require designated employees remain behind briefly to operate fire extinguishers or shut down gas and/or electrical systems and other special equipment that could be damaged if left operating or create additional hazards to emergency responders (such as releasing hazardous materials).

Each employer must review their operation and determine whether total and immediate evacuation is possible for various types of emergencies. The preferred approach, and the one most often taken by small enterprises, is immediate evacuation of all their employees when the evacuation alarm is sounded.

If any employees will stay behind, the plan must describe in detail the procedures to be followed by these employees. All employees remaining behind must be capable of recognizing when to abandon the operation or task and evacuate themselves before their egress path is blocked. In small establishments it is common to include in your plan locations where utilities (such as electrical and gas) can be shut down for all or part of the facility either by your own employees or by emergency response personnel.

To ensure the fastest, most accurate accountability of your employees, you may want to consider including these steps in your emergency action plan:

- Designate assembly areas or areas, both inside and outside your workplace, where employees should gather after evacuating. Assembly locations within the building are often referred to as "areas of refuge." Make sure your assembly area has sufficient space to accommodate all of your employees. Exterior assembly areas, used when the building must be partially or completely evacuated, are typically located in parking lots or other open areas away from busy streets. Try and designate assembly areas so that you will be up-wind of your building from the most common or prevailing wind direction.

- Take a head count after the evacuation. Identify the names and last known locations of anyone not accounted for and pass them to the official in charge. Accounting for all employees following an evacuation is critical. Confusion in the assembly areas can lead to delays in rescuing anyone trapped in the building, or unnecessary and dangerous search-and-rescue operations. When designating an assembly area, consider (and try to minimize) the possibility of employees interfering with rescue operations.

- Establish a method for accounting for non-employees such as suppliers and customers.

- Establish procedures for further evacuation in case the incident expands. This may consist of sending employees home by normal means or providing them with transportation to an offsite location.