Printing Industry eTool

Printing Industry » Screen Printing

Screen printing with its ability to lay down a heavier ink deposit is a process where an industrial woven fabric or "screen" is manually stretched to a predetermined tension, and affixed to a wood or aluminum frame using a suitable adhesive or mechanical means. The woven structure of the screen contains mesh openings which allow the ink to pass onto the substrate in the areas that are not blocked by the stencil material.

Employees then spread and push ink through the screen using a sweeping motion with a squeegee. Following the ink transfer, the screen pulls away from the substrate leaving behind the printed image.

The following identifies potential hazards and possible solutions to reduce the ergonomic hazards within the screen printing process:

- Pre-press

- Press

- Post Press

- Reclaiming Screens, see Cleaning Mesh/Reclaiming Screens

- Folding Textiles

- Materials Handling

Pre-press

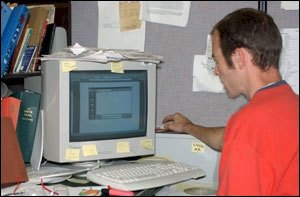

In the modern printing business most pre-press work is done via computer. Images are delivered, checked and edited. The hazards associated with this type of activity are similar to those found in an office environment.

Potential Hazards

Screen printers spend more time on development than other printing crafts since much of their work may require intricate "artistic" applications. Workstations that are not properly designed for computer work may cause stressful postures or motions.

-

Prolonged periods of awkward body postures (i.e., neck bending, torso bending or twisting, raised shoulders) (Figure 1).

-

Repetitive motions (i.e., frequent reaching to a mouse, clicking or dragging) (Figure 1).

-

Contact stress to the legs from chair front and to the arm from desk surfaces.

-

Glare or monitor washout from poor placement of monitor in relation to windows and other bright light sources (Figure 2).

Possible Solutions

(Roll mouse over text below to highlight specific areas in the image.)

-

Establish a training program so that employees can learn how to set up and periodically adjust their workstations (Figure 3).

-

Ensure keyboard and mouse are at proper height and position.

-

Provide appropriate computer-related components and furniture.

- OSHA's Computer Workstations eTool offers assistance identifying, analyzing and controlling hazards in the following areas:

Large frames are placed on work tables and a mesh material is attached to the frames. Mesh must be pulled taut so there are no wrinkles or loose areas. Stretching is accomplished by holding the fabric in a mechanical or manual clamping system which pulls the fabric to the desired tension level. The fabric is then attached to the frame using a suitable adhesive or mechanical fasteners. Screen tensioning can also be produced with self-tensioning frames, where the fabric is clamped into the frame itself and elements in the frame sides are expanded or rolled to create the stretching force needed.

Potential Hazards

-

Depending on the process, technology or tools used to stretch mesh, the activity may require awkward postures and exertion of excessive force.

-

The large size of the screens or related equipment may cause awkward postures when reaching and bending to position the frame, position the mesh over the frame and in clamps, cut the mesh, and remove the frame from the table.

-

Heavy manual lifting and lowering of larger screens on and off the table.

-

Use of tools may require exertion of significant hand force while hand, wrist and shoulder may be in awkward postures (Figure 4).

Possible Solutions

-

Provide adjustable tables (Figure 5) so employees may adjust work height to minimize torso bending. Generally, table height should be below elbow height for tasks that require exertion of significant force and at about elbow height for fine manipulative tasks.

-

Consider corner cutouts or segmented tables. This allows the table size to be contracted or expanded to accommodate the size of frame. Minimizing the size of the table will reduce forward reaching and torso bending.

-

Use 2-person teams to lift larger, heavier frames.

-

Educate employees about proper body mechanics. Back, neck, and wrists should be straight. Elbows in close to the body while supporting a load.

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

-

Explore feasibility of using automated equipment or purchasing pre-stretched screens.

Screens must be thoroughly degreased prior to applying a stencil (emulsion). The screen is cleaned with a brush using water and a degreaser. These steps prepare the surface so that the stencil adheres well. Reclaiming the screen also requires use of a brush and cleaner and involves removal of the tape, stencil material, stains, or ghost images from the screen once the printing process is completed. Reclaimed screens are then degreased in the same process as new screens and reused.

Potential Hazards

-

Awkward postures including bending forward at the waist, wrist bending, and extended reaching to apply degreaser, abrasive and tape to the screen (Figure 6), position frames in the spray booth or other surface to scrub mesh with a brush (Figure 7).

-

Forceful or prolonged gripping to hold and activate power washer hose and trigger, and brushes when cleaning and rinsing mesh.

-

Repetitive or prolonged forceful exertions when using brushes and spray guns, especially on high-volume jobs.

-

Repetitive motions and finger force performed on high-volume jobs.

-

Frequent manual lifting and handling of screens, related equipment or tools.

Possible Solutions

-

Adjust workstation surface height and angle to minimize forward bending and reaching (Figure 8). Suggested modifications include:

-

Provide height and tilt adjustable workstations.

-

If workstation is too short, add blocks under the table legs to raise the work surface, so that employees do not need to bend torso.

-

Where a workstation must be shared between multiple employees and there is insufficient adjustability, adjust height to accommodate the tallest user and provide shorter users with platforms.

-

Provide height-adjustable seating.

-

Modify workstation to provide the option for employees to sit, stand or lean.

-

Encourage employees to work while standing up straight with the elbows in close to the body.

-

If employees must work in awkward body posture for a prolonged period of time, allow frequent micro (one-minute) breaks to change body posture.

-

-

Position screens between hip and shoulder height to reduce bending and reaching. This may be accomplished by incorporating a ledge in the wall of the spray booth or installing a rack or an easel frame to hold the screens.

-

Locate all tools and products within easy reach of the employees to prevent bending forward and reaching to retrieve items (Figure 9).

-

Use tools that minimize force and awkward postures. For example, a long-handled brush for cleaning tasks would reduce forward reaches (Figure 9).

-

Use a brush with an appropriately designed handle to reduce grip force. Generally, the handle should be well rounded and constructed of a material which is non-porous, non-slip (rubber or plastic coated) and have a diameter of about 1.5 inches. The handle should be bent in an appropriate manner to minimize wrist deviation, either to the side or up and down (Figure 9).

-

Use pistol grip handle on hose to keep wrist straight (Figure 10).

-

Consider placing power washer and hose on a counter-balance to reduce the force required to hold and maneuver the gun and hose when spraying.

-

Consider job rotations to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

-

Transport heavier screens using a wheeled cart or mobile easel stand to reduce manual lifting and carrying.

After a screen is stretched over a wood or aluminum frame, it is coated with an emulsion for further processing. Areas of the screen are blocked off with a non-permeable material (i.e., a stencil) which is a negative of the image to be printed and is exposed to UV light. The negative hardens and the softer image is washed off leaving a stencil with the image as open spaces where the ink will be pressed through to coat the substrate.

Potential Hazards

-

Bending forward at the waist, wrist bending, and reaching to apply block out products and tape (Figure 11 and 12).

-

Repetitive use of forceful finger exertions with wrist bending for high volume jobs.

-

Manually lifting heavy screens or related equipment.

Possible Solutions

- Adjust workstation surface height and angle to minimize forward bending and reaching (Figure 13). Suggested modifications include:

-

Provide height and tilt adjustable workstations.

-

If workstation is too short, add blocks under the table legs to raise the work surface so that employees do not need to bend torso.

-

Where a workstation must be shared between multiple employees and there is insufficient adjustability, adjust height to accommodate the tallest user and provide shorter users with platforms.

-

Provide height-adjustable seating.

-

Modify workstation to provide the option for employees to sit, stand or lean.

-

Encourage employees to work while standing up straight with the elbows in close to the body.

-

If employees must work in awkward body posture for a prolonged period of time, allow frequent micro (one-minute) breaks to change body posture.

-

-

Locate all tools and products within easy reach of the employee to prevent bending forward and reaching to retrieve items.

- Investigate a modified for coating trough handle that is padded, conforms to the shape of the hand, minimizes wrist bending and widens the grip diameter. For example, see those solutions created for squeegee handles.

-

Control of Ergonomic Hazards from Squeegee: Handles in the Screen-Printing Industry. NIOSH Publication No. 97-137, (1997, June).

-

-

Consider use of a mounted tape dispenser.

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

Ink must be properly prepared based on the specific printing job. This involves retrieving correct containers from storage areas, mixing colors, adding thinners when necessary, and attaining the correct amount of ink for the specific printing job.

Potential Hazards

-

Awkward body postures including torso bending, reaching above shoulder level, or extended reaches to retrieve ink containers stored on shelves.

-

Significant force used to lift heavy ink containers and move drums.

-

Repetitive pinch gripping of ink containers when filling inkwells (Figure 14).

Possible Solutions

-

Use an adjustable workbench for mixing ink so that pouring and mixing are performed at or slightly below waist height to promote neutral posture (back straight with elbows in close to the body).

-

Store most frequently used containers between shoulder and waist height to minimize bending and reaching.

-

Order supplies in smaller volumes such as gallon bottles rather than 5-gallon pails, to reduce heavy manual lifting (Figure 15).

-

Use a pushcart to retrieve and transport multiple containers from storage to the workbench.

-

Use mechanical assistance such as a drum truck to move heavy drum barrels.

-

Mix ink at the workbench instead of holding and mixing over the inkwell to help reduce strain, especially when containers are heavy.

Press

Commercial and industrial screen printing is done on single and/or multicolor presses with varying degrees of automation. Each color is applied separately from its own screen as the substrate automatically moves to the next step in the process. The employee only loads the substrate to be printed (textiles, paper, etc.) on the print bed or print table, making sure that it is firmly secured in place and unloads the finished product at the end of the process.

Potential Hazards

-

Prolonged sitting or standing to feed or remove material from equipment and conveyors.

-

Repetitive bending, reaching, and exertion of finger force to feed materials into the press (Figure 16).

-

Repetitive bending and twisting to obtain substrate from supply areas, and remove finished product from presses or dryers for shipping.

-

Manual lifting and carrying heavy or bulky substrate or finished product from supply areas to packing areas.

Possible Solutions

-

Alternate postures between sitting and standing to reduce fatigue.

-

Use sit/stand stools for rest and better access.

-

Provide employees with shoe insoles or anti-fatigue floor mats when standing for extended periods.

-

Adjust the chair or machine feed area so that employees may keep their arms close to their body and minimize bending during the feeding process (Figure 17).

-

Arrange substrate and materials within easy reach to reduce twisting. Where possible, place material at no more than a 45 degree angle from in front of worker. This material should be accessible while keeping elbows in close to the torso.

-

Use carts to move material from storage to work area, then to packing areas.

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

Ink is placed onto a screen and is spread by a printer who manually pushes or pulls the hand-held squeegee across the surface of the screen. The printer will usually hold the squeegee at a 60-85 degree angle from the screen surface in the direction of the pull and apply enough force to push the ink through the screen to the substrate below.

Potential Hazards

-

Awkward postures including torso bending, reaching, and bending the wrists to apply the ink (Figure 18).

-

Forceful pinching of the squeegee and pressure on shoulder and the palm of the hand to apply downward force (Figure 18).

-

Highly repetitive motions and postures when performing high-volume jobs (Figure 18).

-

Manual lifting of heavy screens or related equipment to set up job.

Possible Solutions

- Adjust workstations surface height and angle to minimize unnecessary forward bending and excessive reaching. Suggested modifications include:

-

Provide height and tilt adjustable workstations.

-

If workstation is too short and adjustment is not possible, add blocks under the table legs to raise the work surface so that employees do not need to bend torso.

-

Where a workstation must be shared between multiple employees and there is insufficient adjustability, adjust height to accommodate the tallest user and provide shorter users with platforms.

-

Modify workstation to provide the option for employees to sit, stand or lean.

-

Encourage employees to work while standing up straight with the elbows in close to the body.

-

If employees must work in awkward body posture for a prolonged period of time, allow frequent micro (one-minute) breaks to change body posture.

-

- Use a padded squeegee handle that conforms to the shape of the hand, and widens the grip diameter.

-

Control of Ergonomic Hazards from Squeegee: Handles in the Screen-Printing Industry. NIOSH Publication No. 97-137, (1997, June).

-

-

Lean forward somewhat to allow body weight to assist with exertion of downward force on squeegee (Figure 19).

-

Partial or full automation of this process step may eliminate ergonomic concerns and promote a faster, possibly more accurate application process.

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

Post Press

Garments or textiles are generally folded after they have been printed and cured.

Potential Hazards

-

Prolonged standing.

-

Awkward and prolonged postures of the torso and neck maintained for long periods of time when working at a low work surface (Figure 20).

-

Repetitive reaching when dealing with large garments.

-

Elevated elbow postures when working on work surfaces that are too tall.

Possible Solutions

-

For smaller items try to alternate postures between sitting and standing to reduce fatigue from lack of movement.

-

Use an adjustable chair when sitting.

-

Provide employees with shoe insoles or anti-fatigue floor mats (Figure 21) when standing for prolonged periods of time.

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

-

Consider an automatic folding machine.

- Provide an adjustable height and tilt workstation so that most work may be done slightly below elbow height. Suggested modifications include:

-

Provide height and tilt adjustable workstations.

-

If workstation is too short and adjustment is not possible, add blocks under the table legs to raise the work surface so that employees do not need to bend torso.

-

Where a workstation must be shared between multiple employees and there is insufficient adjustability, adjust height to accommodate tallest user and provide shorter users with platforms.

-

Materials Handling

Printed textiles must be packed into boxes or other packaging and palletized for shipping.

Potential Hazards

-

Repetitive reaching and twisting to place items into boxes (Figure 23).

-

Elevated arms when reaching up and over the top of shipping boxes placed on packing tables (Figure 22).

-

Deep torso bending or squatting to place garments in shipping boxes placed on the floor (Figure 24).

-

Forceful manual lifting and carrying of product and filled boxes for palletizing and shipping.

Possible Solutions

-

Place product and/or boxes at about waist height to eliminate extended reaching, torso and neck bending and to keep arms close to the body (Figure 25).

-

Place boxes adjacent to the work surface in order to slide product into boxes and eliminate or reduce lifting of product or stooping to place product into boxes (Figure 26). This may be accomplished by placing boxes on carts, stands or tilt tables.

-

Place an object or wedged-shaped device under the far side of the box. This tips the box towards the employee to improve the angle and access for loading.

-

Use automated taping machine to reduce force exertion and improve body posture when taping boxes (Figure 27).

-

Provide a height and tilt adjustable packing stands so that packing height can be adjusted and the opening can tilt towards the employee.

Depending on customer specifications, printed product may need to be packed and palletized before it is shipped to the customer. Bundled product may be heavy and loading height may vary from almost ground level to above head height. After a load has been prepared on a pallet, it is often wrapped with plastic to maintain its stability during transit.

Potential Hazards

-

Forward bending and reaching to grab bundles or boxes from the conveyor or accumulation tables.

-

Repetitive reaching, twisting, and bending to stack and position finished material on pallets (Figure 28).

-

Forceful, repetitive gripping to retrieve printed materials from presses, and load on pallets. This is especially true when boxes without hand cutouts or handles are used.

-

Bundles may be too heavy or bulky for an individual to lift safely.

-

Torso bending and twisting as well as reaching out and away from the body to place items on pallets. The height of material on the bottom of the pallet is typically only a few inches above the floor (Figure 29).

-

Forceful gripping and pulling of plastic wrap rolls when wrapping pallets.

-

Employees must bend at the waist to manually wrap the bottom of the pallets while supporting the plastic wrap dispenser.

-

Manual wrapping of product on pallets causes stress on the lower back, shoulders and arms (Figure 30).

-

Physical stress associated with positioning large plastic wrap rolls into automatic wrapping machines.

-

Repetitive lifting of wooden pallets weigh between 40 and 70 pounds causes stress to the lower back, shoulders and arms.

Possible Solutions

-

Optimize bundle size and weight for one-person lifting. Generally, a single bundle should not weigh in excess of 40 pounds and should be shoulder width (about 24 inches).

-

Provide boxes with hand holds or cutouts.

-

Adjust the height of the conveyor or provide a platform for the employee to stand on so that the bundles are slightly below waist height and close to the employee's body. This will provide optimal leverage for the employee to lift and stage bundles without bending or reaching.

-

Use a slide or roller conveyor so employees can pull or slide product closer to the body before it is lifted.

-

Minimize twisting of torso when loading between conveyor and pallet. Move the feet to face the load instead of twisting.

-

Design the workstation to minimize the amount of turning and carrying necessary. Place box or pallet close to conveyor.

-

Provide anti-fatigue mats around machines to reduce the stress of standing for prolonged periods of time (Figure 31).

-

Consider job rotation to tasks with different ergonomic stressors. Employees should rotate whenever possible to a variety of tasks to avoid prolonged periods of repetitive motions or maintaining the same postures. To facilitate rotation, efforts should be made to cross-train employees in several operations such as ink mixing, reclaiming, inventory control, and office work.

-

Use height-adjustable lift devices to keep the load close to waist level. This enables the employee to position the load close to the body by turning the pallet (Figure 32).

-

Consider using take-away conveyors (roller or powered) (Figure 33) to move finished materials to the next processing station or to an area where the employee palletizes loads in a more ergonomic manner.

-

Use forklift to position pallets off the floor and at a matching height adjacent to the conveyor.

-

Consider use of automatic pallet wrapper and automatic strapping machine (Figure 34 and 35).

-

If manual wrapping must be performed, use rolls that weigh as little as possible to minimize the lifting hazard and use a roll holder with a handle to improve hand postures.

-

Whenever possible, elevate the pallets used for receiving processed materials to minimize bending. This may be achieved by placing pallets on a platform that positions the load close to waist level. The loaded pallet is then placed on several empty pallets (Figure 36) to raise the height of the raw materials. This will minimize bending of the torso. Secure the pallets to reduce the risk of falling materials.

-

Use lighter, plastic pallets (Figure 37). Plastic pallets can weigh half of what a wood pallet weighs. The employees of both the company and customer will benefit from the reduction in weight.

-

Train employees on proper lifting techniques.

-

Keep back straight.

-

Keep elbows in and close to torso.

-

Keep load close to and in front of body.

-

Avoid twisting.

-

Get firm grip, lift smoothly, and avoid jerking motions.

-