Sawmills eTool

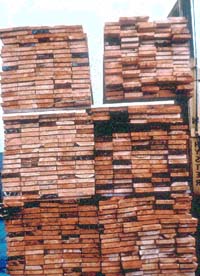

Lumber Storage » Lumber Sorting, Stacking, and Piling

-

>> Lumber Handling Vehicles

Hazard/Solutions

Workers may be struck or crushed by lumber due to unintentional movement of the pile.

-

In stacking units of lumber, pile foundations must be designed and arranged to support maximum loads without sinking, sagging, or permitting the piles to topple. In unit package piles, substantial bolsters or unit separators must be placed between each package directly over the stickers. 1910.265(c)(27)(i)

-

Long units of lumber may not be stacked upon shorter packages except where a stable pile can be made with the use of package separators. 1910.265(c)(27)(ii)

-

Unit packages of lumber need to be provided with stickers as necessary to insure stability under ordinary operating conditions. 1910.265(c)(27)(iv)

-

Stickers must extend the full width of the package, be uniformly spaced and be aligned one above the other. Stickers may be lapped with a minimum overlapping of 12 inches. Stickers may not protrude more than two inches beyond the sides of the package. 1910.265(c)(27)(v)

- Piles of lumber that have become unstable must be immediately made safe, or, the area into which they might fall must be fenced or barricaded and employees must be prohibited from entering it. 1910.265(c)(27)(iii)

-

The height of unit package piles is dependent on the dimensions of the packages and must provide stability under normal operating conditions. Adjacent lumber piles may be tied together with separators to increase stability. 1910.265(c)(27)(vi)

Hazard/Solutions

Workers may be struck or crushed by moving lumber.

-

Lumber lifting devices on all stackers must be designed and arranged to minimize the possibility of lumber falling. 1910.265(c)(26)(ii)

-

Provide a means to positively block the hoisting platform when employees must go beneath the stacker or unstacker hoist. 1910.265(c)(26)(iii)

-

Every manually operated control switch must be properly identified readily accessible to the operator. 1910.265(c)(26)(iv)

-

The design of main control switches must allow them to be locked in the open position. 1910.265(c)(26)(v)

-

The hoistway side openings at the top level of the stacker and unstacker must be protected by enclosures of standard railings. 1910.265(c)(26)(vi)

-

When the hoist platform or top of the load is below the working platform, the hoistway openings must be guarded. 1910.265(c)(26)(vii)

-

The lower landing area of stackers and unstackers must be guarded by enclosures that prevent entrance to the area or pit below the hoist platform. Entrances should be protected by electrically interlocked gates which, when open, will disconnect the power and set the hoist brakes. When the interlock is not installed, other positive means of protecting the entrance must be provided. 1910.265(c)(26)(viii)

-

Every stacker and unstacker must be inspected at frequent intervals and all defective parts must be immediately repaired or replaced. 1910.265(c)(26)(ix)

-

Safe means of entrance and exit must be provided to permit cleaning of pits. 1910.265(c)(26)(x)

-

Where the return of trucks from unstacker to stacker is by mechanical power or gravity, adequate signs, warning devices, or barriers must be erected to prevent entry into the hazardous area. 1910.265(c)(26)(xi)

-

The green chain is the area where lumber is sorted and piled. Additional Green Chain Images