Sawmills eTool

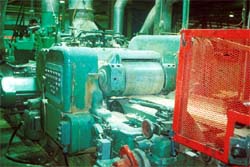

Planers, also called surfacers, are woodworking machines used to dress and size rough-sawed lumber on one or more sides, planing boards to an even thickness.

Operator Involvement

The operator adjusts the planer for the cut and then feeds stock into the in-feed side of the machine. The surface board is retrieved from the out-running end.

Hazard/Solutions

Contact may occur with the cutter head, belts and pulleys, or other machinery.

-

All cutting heads must be guarded. 1910.265(e)(6)(i)(a) Provide barriers at the loading and unloading ends to keep hands out of point of operation.

-

Pressure feed rolls and "pineapples" must be guarded. 1910.265(e)(6)(i)(c)

-

Completely enclose belts and pulleys of line shaft with sheet metal or heavy mesh guards; guards must be used regardless of the location of the line shaft. [29 CFR 1910.219(a)(1)].

-

Cover cutting heads with a metal guard or cage. The exhaust system may be integrated with the guard.

[29 CFR 1910.213(n)(1)].

-

Side head hoods must be of sufficient height to safeguard the head setscrew. 1910.265(e)(6)(i)(b)

-

Guard levers or controls to reduce the possibility of accidental operation. 1910.265(e)(6)(i)(d)

Hazard/Solution

Clothing, hair, or hands may be caught by and pulled into, the automatic feed mechanism.

-

Guard feed rolls with a wide metal strip or bar that will allow boards to pass but that will keep the operators' fingers out [29 CFR 1910.213(n)(3)].

Hazard/Solution

Stock may be thrown back at the operator after being caught by the cutter head.

-

Install anti-kickback fingers on the in-feed side across the width of the machine. Stand back once the boards have been put through to avoid injuries from kickback and flying splinters. Do not feed boards of different thickness. Thinner boards will be kicked back.

Hazard/Solution

Work pieces, wood chips, and/or splinters may be thrown by the cutting action.

-

Use a barrier or guardrail when the machine is running.