Sewing and Related Procedures » Scissor Work

Employees working at manual scissor stations often have repeated exposure to awkward wrist postures, repeated grip force, and contact stress to the hands and fingers. This task may also require the employee to bend over a table and reach with arms fully extended to cut the full length of the fabric. Scissor work may also include tedious or small range hand motions during finishing or quality control tasks. Following are some possible risk factors involved in this process, and possible solutions.

Potential Hazard

-

Holding the wrists in an awkward position while cutting with scissors can cause injury to the wrist.

Possible Solutions

-

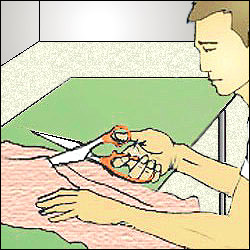

Invest in tools designed to promote neutral joint postures (Fig 1).

-

Use electric, pneumatic, or otherwise partially automated tools.

-

Reduce the amount of force needed to operate tools by:

- Keeping tools well maintained (i.e., oiled and cleaned), and

-

Instituting a tool sharpening program.

-

Institute job rotation through tasks that do not require cutting with scissors.

Potential Hazards

-

While cutting material, employees often bend over a table, which may cause low back injuries (Fig 2).

-

Employees must extend their arms to cut through a complete piece of fabric (Fig. 2).

Possible Solutions

-

Use shorter-width tables so workers do not have to bend and reach so far (Fig 2).

-

Provide height- and tilt-adjustable tables; tables should be set at elbow height.

-

Feed fabric to the worker rather than making the worker reach for the fabric.

-

Use electric, pneumatic, or otherwise partially automated tools (Fig 3).

-

Institute job rotation through tasks that do not require bending at the waist and cutting.

Potential Hazard

-

Cutting often requires employees to use repeated wrist motion, grip force, and small range hand motions.

Possible Solutions

-

Reduce the amount of force needed to operate tools by:

- Keeping tools well maintained (i.e., oiled and cleaned), and

-

Instituting a tool sharpening program.

-

Invest in tools designed to promote neutral joint postures.

-

Use electric, pneumatic, or otherwise partially automated tools (Fig 4).

-

Institute job rotation through tasks that do not require cutting with scissors.