Sewing Station Design » Stitching

Stitching involves taking cut material, placing it on the sewing mount, then running it through a sewing machine. This operation may require pinch grips and awkward arm, neck, and trunk postures. Force may also be required to push fabric through the machine. Some of the common risks and possible solutions associated with stitching are listed below.

Potential Hazards

-

Workers reach overhead (Figs. 1 & 2), to the side (Fig. 3), behind, or down into tubs to pick up or place fabric. This action can cause stress on the arms, neck, shoulders, and back.

-

Workers bend/twist to pick up fabric (Fig. 4), which can hurt a worker's back and shoulders.

Possible Solutions

-

Minimize overhead reach by:

- Lowering the rack (Fig. 5); or

- Placing station on platform or using height-adjustable portable clothing racks or tables.

-

Minimize reaches to the side or behind associated with picking up new product or placing completed fabric by:

- placing fabric/bins closer to the worker (Fig. 6);

- placing fabric/bins at table height;

- using height-adjustable fabric containers;

- adding an extension to work table; or

- using an automated or conveyor system that transports the fabric directly to and from the worker.

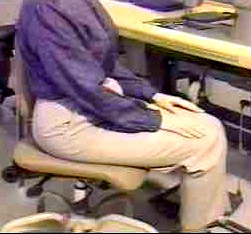

- Use swivel chairs (Fig. 7), which allow workers to turn to get bundles and pieces, rather than twisting to reach to the side or behind. Swiveling can also make it easier for workers to sit down and get up from the workstation.

Potential Hazard

-

When setting up material for stitching, workers may have to flex or bend their necks to view the position of the fabric.

Possible Solutions

-

Use automatic feeding and set up, which eliminates the operator using awkward postures.

-

Provide proper lighting:

- Use adjustable task lighting to make it easier for the worker to see product during set up (Fig. 8).

- Ensure bulbs are replaced frequently so they are functional at all times.

- Provide properly positioned general overhead lighting.

Potential Hazard

- While manipulating fabric, employees repeatedly use a forceful pinch grip (Fig. 9) between the thumb and index finger.

Possible Solutions

-

Use friction-increasing aids (Fig. 10) on fingers to reduce amount of force exerted in the pinch grip.

-

Analyze tasks to determine force requirement and use job/task rotation through tasks not requiring pinch grip.

Potential Hazard

- Employees push fabric through the sewing machine, which may require extending arms, bending at the waist, and applying force (Fig. 11).

Possible Solutions

-

Use height adjustable tables (Fig. 12), which, when properly adjusted, may reduce arm extension and bending at the waist.

-

Allow the machine to pull the fabric through rather than having the operator push the fabric.

-

Reduce the distance between the operator and the machine.