Sewing and Related Procedures » Sewing Station Design

Employees encounter several risk factors at sewing workstations, such as awkward arm, neck, trunk, and leg postures. These postures are influenced by the size of the worker and the design of the workstation. This section explains potential hazards encountered at the workstation and a general description of a proper workstation design.

Potential Hazards

-

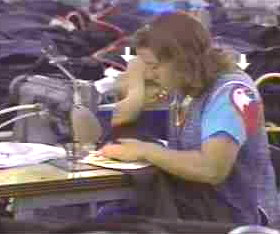

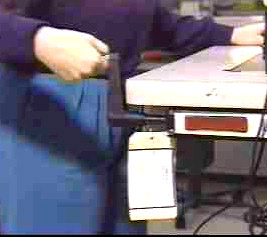

Workers often maintain awkward shoulder, elbow, and wrist postures (Fig. 1) while sewing because of improper chair height or position.

-

Employees must sit or stand for long periods in the same position, resulting in soreness of the back and neck, and/or buttocks, and reduced circulation to the legs.

Possible Solutions

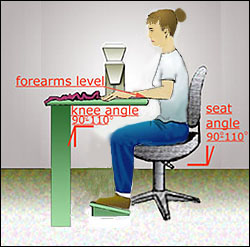

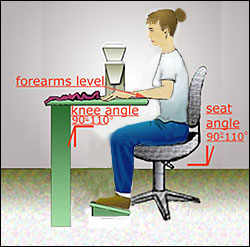

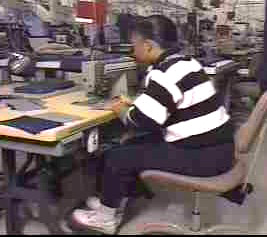

Use easily adjustable chairs (Fig. 2) to minimize awkward postures, and provide training on how to properly use them.

-

Chairs should have:

- easily adjustable height, seat tilt, and backrest position;

- padded back rest with rounded edges that supports worker's lower back;

- no wheels, or wheels that lock;

- a gently sloped or "waterfall" front edge to help prevent the chair's edge from pressing into the back of the legs; and

- a cushioned/contoured seat, which distributes the worker's weight so no body part gets all the pressure.

To choose a proper chair, consider the amount of movement the task requires, and the size of the worker. For tasks that require a lot of twisting, Fig. 2 is desirable.

-

Chairs should be placed at an appropriate distance from the workstation, so workers can perform tasks without pulling their elbows away from the body (Fig. 3).

-

Motor placement should not interfere with proper chair distance.

- Chair height is correct when the work surface is at elbow height. Ideally, in this posture, the entire sole of the foot should rest on the floor, and the back of the knee should be slightly higher than the seat of the chair (Fig. 4). (This illustrates the importance of also having an adjustable table.) The seat may be slightly lower when the worker uses a treadle or pedal.

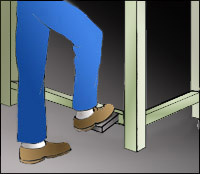

- Provide sit/stand workstations, which encourage changing posture (Figs. 5 & 5a).

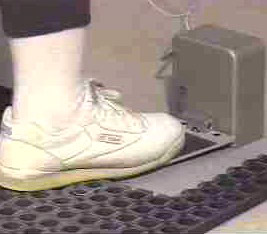

- Provide anti-fatigue mats (Fig. 6) for workers who are standing for prolonged periods. Anti-fatigue mats promote better circulation and reduce fatigue in the lower extremities.

-

Schedule frequent, short breaks to stretch and/or change position.

-

Provide training on importance of breaks to help reduce injuries.

Potential Hazards

- Workers maintain awkward shoulder, elbow, and wrist postures while sewing because of improper table height (Fig. 7).

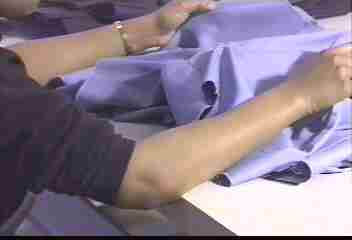

- Employees resting forearms or wrists on sharp edges may cut off blood circulation, pinch nerves, and cause injury to the arms or hands (Fig. 8).

Possible Solutions

- Provide both height- and tilt-adjustable tables (Fig. 9), which can help employees access their work without using awkward postures.

- Tables should be adjusted so the work is at elbow height and wrists are kept straight (Fig 10). If the table is too low, workers will have to hunch forward, putting strain on the back, neck, and shoulders. If a table is too high, workers will have to raise their shoulders to get their arms high enough to work. This posture tires the neck, shoulder, and upper back muscles and may result in muscle pain.

- For sit-down work, the table should also be high enough to allow room underneath for the worker's legs (Fig. 11). The table top should not press on the worker's thighs. Workers who use a treadle need more room than those who don't so they can move their legs more easily.

-

Tables may be tilted slightly toward workers, to enable them to see the work more easily and to reduce awkward wrist postures (Fig. 12).

-

When sewing heavy fabric, the table may be tilted away from the worker, which may help pull the fabric through the machine and lessen manual force applied by the worker.

- Edges of work surfaces should be padded or rounded, so workers can rest their arms against them (Fig. 13).

Potential Hazards

-

Employees operating a treadle for prolonged periods must maintain awkward and unbalanced posture (Fig. 14).

-

Employees required to apply a constant treadle force must maintain static lower extremity postures.

- Workers may also maintain poor posture if treadle is too close or too far away (Fig. 15).

Possible Solutions

-

Design treadle to require less force (Fig. 16), allowing the use of a sit/stand workstation.

-

When feasible, use hip switches or redesigned foot treadles to eliminate the need to apply constant standing pressure.

- Provide adjustable treadle so the worker can place it in a comfortable position and get as close to the table as possible (Fig.17).

- Use job/task rotation through tasks that do not require constant leg pressure and awkward leg posture.