Grocery Warehousing eTool

Grocery Warehousing » Packaging

Products vary in weight — potentially up to 100 pounds — and are shipped to the warehouse in a variety of containers, including boxes, bags, and cans. The shape, weight, and/or material of the package can greatly affect the stress that a grocery warehouse employee experiences.

Potential Hazard

-

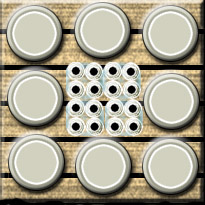

In cold or freezer warehouses many boxes are excessively heavy (Figure 1), they may weigh as much as 100 pounds. Manually lifting loads in this weight range places great stress on the employee's muscles. Back injuries, such as muscle strain and disc injury, can occur when repeatedly lifting heavy objects.

Dominos cuts sugar packages Domino Sugar reduced its bundled packages of sugar from 60 pounds to 40 pounds below OSHA’s suggested limit of 50 pounds. This change will make the bundles easier to handle and reduce the total weight of each by 33 percent. All three of its manufacturing locations have adjusted their packaging equipment to accommodate the weight modifications. The first shipment of 40-pounds bundles began in June. Poll Shows public view of OSHA’s priorities

Figure 2: Some suppliers are willing to modify weight of packages.

Possible Solutions

-

Work with suppliers to provide product in smaller, lighter containers (Figure 2).

-

Improve access to heaviest items. Employees should be able to access these items without bending at the waist, pulling the elbows away from body while reaching, or twisting. Redesigning storage racks and transport devices can greatly improve the employee's ability to maintain these neutral postures.

-

Provide handhold cutouts or handles on all heavy products.

-

Work with suppliers to ensure that container integrity will be adequate so the box, bag, or bucket will not accidentally break, rip, or pull apart during lifting operations.

-

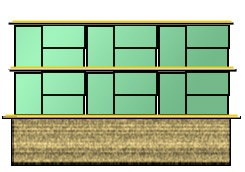

Load pallets with lighter product in the center and heavier on the outer edges to ensure easier access and lifting of the heavier items (Figure 3).

Potential Hazard

-

Many packages do not have handles or handle cut-outs (Figure 4). This makes heavy cases difficult to grasp and/or retrieve. This can also force employees to use awkward postures when lifting product. Without hand cut-outs or handles, employees must press on the sides of boxes, slip fingers under the lips of products, or grasp the loose material of bags to gain control. These techniques place strain on the hands and shoulders.

Possible Solution

-

Encourage suppliers to provide product in stable boxes with hand hold cut-outs or handles (Figure 5). This is especially important for product that is extremely heavy.

Potential Hazard

-

Many cases are now packaged in plastic rather than cardboard (Figure 6). Plastic from one package may stick to another package. The added resistance of the plastic can create additional stress to the hands, arms, shoulders, and back. Selectors often pull cases toward their body to gain better lifting advantage. Forces required to pull the cases with these restrictions may actually be greater than the weight of the case.

Possible Solutions

-

Work with suppliers to get a slip sheet between the layers (Figure 7). This will decrease the force needed to slide product toward the employee.

-

Treat these cases as if they are heavy loads and provide additional head room and space on the side of stacks for access.

-

Have suppliers wrap only the sides and tops of cases, leaving the cardboard bottom exposed to facilitate sliding.

Potential Hazards

-

Wooden Pallets weigh between 40 and 70 pounds and may be lifted several times during a work shift (Figure 8). This repeated lifting can cause stress to the lower back.

-

Splinters from handling the wood are also a hazard to the worker.

Possible Solutions

-

Request that suppliers provide product on lighter, plastic pallets (Figure 9). The employees of both the warehouse company and supplier will benefit from the reduction in weight.

-

Plastic pallets easily nest together to reduce the space of stacking. They also eliminate splinters and uneven surfaces that employees may step on when walking over pallets.

-

Provide a pallet dispenser to reduce handling of pallets (Figure 10). This device allows Selectors to drive their pallet jack to the dispenser. An empty pallet is then automatically loaded onto the forks without manual lifting.

Potential Hazards

-

After a load has been built, it is generally wrapped with plastic to maintain its integrity during transit. Employees may be injured when performing this task manually. They must bend at the waist to wrap the bottom of the pallets while supporting the plastic dispenser (Figure 11).

-

Employees often stick their fingers into the open end of the tubes to stream off the wrap. This increases the risk of cuts to the fingers.

Possible Solutions

-

Use an automatic plastic wrapping machine with palletized product sitting on a turntable (Figure 12). This ensures the employee will not have to bend at the waist to wrap the pallet.

-

If manual wrapping must be performed, use rolls that weigh as little as possible to minimize the lifting hazard. A handle (Figure 13) will prevent employees from placing their fingers into the tube, thus decreasing the risk of cuts.

Potential Hazards

-

Boxes are usually cut open using a razor knife. If the knife is too small (Figure 14), employees may use a pinch grip, which can stress the tendons of the hands.

-

The use of in-line knives (i.e., handles are in-line with the cutting blade) can cause the employee to twist the wrist while exerting finger force, increasing the risk of tendonitis and carpal tunnel syndrome.

Possible Solution

-

Use ergonomic razor-knives that require less wrist bending, and have substantial handles that require less finger force for control (Figure 15).