Grocery Warehousing eTool

Grocery Warehousing » Storage

Most goods in the grocery warehouse are stored for a period of time. Racking is used to expand the amount of storage that is possible. Metal racks are used for storage and the area created within the racking is called a pick bin or slot. Slots range in size, depending on the products stored.

Potential Hazards

-

Palletized product is stored in pick bins. Typically pallets are placed on the floor (Figure 1), which requires employees to bend at the waist to access palletized loads that come to the warehouse stacked only a few feet high, or may be unloaded to the point where they are only a few feet high. Even when these pallets are stored in taller slots (Figure 1), employees must bend at the waist to access product. This is a significant problem since the heaviest product is usually in the shortest stacks.

-

Low racking can force employees to bend at the waist to access loads. Loads in bottom bins (Figure 2), will require forward torso bending to reach under the rack, even when the top levels of the stack are at waist height or higher.

Possible Solutions

-

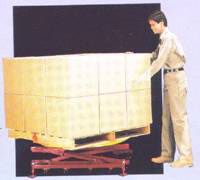

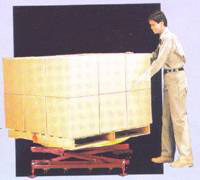

Whenever possible, elevate the pallets within a slot bin. The best technique is to place a palletizer into a tall bin (Figure 3). A palletizer will lower in height under the weight of a full pallet, then will raise the load as items are removed.

-

The use of a turntable (Figure 4) allows employees to reposition the load. This keeps the load close to the body

-

Pallets that do not have product stacked above waist height may be elevated by placing other empty pallets under the load. Care must be taken so the top level of the heavy product is not raised higher than mid-chest height (Figure 5).

-

Raise the bottom level of racking so loads are at heights where torso bending is not necessary (Figure 6).

-

Provide a device such as a forklift with a built-in vacuum hoist. The strong suction can lift up to 150 lbs (Figure 7).

Potential Hazard

-

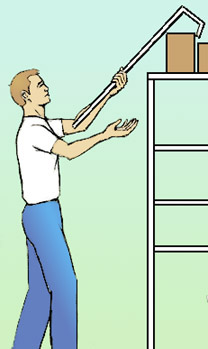

Employees often reach above shoulder height (Figure 8) to access products on upper shelves. This causes stress to the shoulders and back. Additionally, lifts above shoulder height often require awkward hand and wrist postures.

Possible Solutions

-

Use elevated rack locations as the overstock storage area. Pallets of product should be lowered to more appropriate heights prior to being selected. Selections should be performed with arms close to the body.

-

Provide employees with "Pick Sticks" or "Bow Peep" hooks to pull small, light-weight product closer to the edge prior to lifting (Figure 9).

Potential Hazards

-

Double or triple slotting (Figure 10 and 11) is used to maximize shelving space so the greatest amount of product can fit in the smallest amount of space may increase ergonomic stressors such as bending and elevated reaches. Workers may be forced to bend at the torso to reach under low racking to access product (Figure 10).

-

This product may be stacked at desirable heights that would not otherwise, if not for racking interference, require workers to bend at the torso. Workers must reach above shoulder height to access materials placed on three-tier racking (Figure 11) or to access tall, palletized loads placed on two-tiered shelving. In general bottom and top racking in three tiered systems creates significant access issues.

Possible Solutions

-

Provide full slotting, especially for product that is heavy or bulky, so employees can have better access without undue reaching or bending (Figure 12).

-

Slower moving product that is fairly compact can be warehoused using gravity fed flow racks (Figure 13). These racks allow highly condensed usage of warehouse space. However, hazards are created by this type of racking since it must be loaded by hand from the back of the rack. This can require repeated elevated reaches, repeated bending of the torso, as well as using box openers to cut open shipping boxes. Also, Selectors must pull product over the stop lips that keep the product from sliding out onto the floor. Heavy product in the slot creates additional pressure when lifting boxes over the stop lips.

Potential Hazard

-

Product is often removed from the front of pallets first. This leaves the remaining product stacked in the back of pallets, where employees must reach (Figure 14) to access and lift product. This creates additional stress on the shoulders and back.

Possible Solutions

-

Develop a product rotation process where pallets are regularly turned using a forklift or pallet truck after the majority of product has been removed. This involves pulling the pallet out of the slot, turning it 180 degrees and replacing it into the slot

-

Place pallets on turntables (Figure 15) so the pallet can be turned and optimal access to the product can be maintained at all times.

-

Roller and channel devices allow the load to be pulled out for better access. Addition of a turntable at the end of such a device will allow the pallet to be turned and then replaced into the slot with the load closer to the front.

-

Provide wider slots, especially for heavier product, so Selectors can walk into the slot and access all sides of the pallet. Stockers should be trained to leave at least 16 inches between pallets so there is enough space for Selectors to move around the pallet during selection.

Potential Hazard

-

Aisle width may be insufficient for access to faster-moving product. This may create congestion (Figure 16) that forces Selectors to stop farther from the pick slot and carry product longer distances to the pallet jack. Selectors may be tempted to carry multiple parcels at the same time to save trips.

Possible Solutions

-

Increase the width of aisles where fast-moving product is located. This will allow more pallet jacks to get closer and will reduce the distance that loads must be carried.

-

Stagger the start times for Selectors at the beginning of the day so that fewer Selectors hit the same slots at the same time. Five to 10 minute start differentials should provide adequate spacing for sufficient disbursal of Selectors.