Ethanol Processing

Table of Contents:

- Introduction

- Ethanol Industry and Process Descriptions

- Ethanol Manufacturing Health and Safety Hazards

- Safety Measures

- Engineering Controls for Flammable Liquids

- Safe Work Practices When Working with Flammable Liquids

- Engineering Controls to Prevent Equipment Ruptures

- Safe Work Practices to Prevent Equipment Ruptures

- Engineering Controls for Combustible Dust Hazards

- Safe Work Practices for Combustible Dust Environments

- Engineering Controls for Engulfment Hazards

- Safe Work Practices for Engulfment Hazards

- Personal Protective Equipment for Engulfment Hazards

- Engineering Controls for Hazardous Noise Levels

- Hearing Conservation Program

- Hearing Protection Devices

- Engineering Controls for Hazardous Substances

- Safe Work Practices to Protect Workers from Hazardous Substances

- Personal Protective Equipment (PPE) to Protect Workers from Hazardous Substances

- Engineering Controls for Confined Spaces

- Safe Work Practices for Confined Space Hazards

- Personal Protective Equipment for Confined Space Hazards

- Engineering Controls for Motor Vehicle Hazards (e.g., loading, unloading, operating)

- Safe Work Practices for Motor Vehicle Operation

- Lockout/Tagout of Hazardous Energy

- Emergency Planning

- Investigating/Inspecting Ethanol Processing Facilities

List of Appendices

- Appendix A Summary of Hazards and Controls

- Appendix B List of Some of the Standards Applicable to Ethanol Manufacturing Facilities

- Appendix C Safe Entry Requirements for Above Ground Storage Tanks

- Appendix D Producing Ethanol from Cellulosic Materials

List of Figures

- Figure II.1. Ethanol Characteristics

- Figure II.2. Map of Ethanol Production Facilities in the U.S. (USDA, 2013b)

- Figure II.3. Growth in U.S. Ethanol Production 1980-2013 (RFA, 2014)

- Figure II.4. Current Breakdown of Domestic Ethanol Manufacturing by Feedstock

- Figure II.5. Image of a Corn Kernel

- Figure II.6. Nutritional Makeup of Shelled Corn

- Figure II.7. Chemical Process in Corn Dry-Milling

- Figure II.8. Corn Dumped into Receiving Pits

- Figure II.9. Bucket Elevator and Storage Silo

- Figure II.10. Corn Cleaning Unit Operation

- Figure II.11. A Typical Corn Milling Device

- Figure II.12. Ethanol Fermentation Tanks

- Figure II.13. Ethanol Distillation Columns

- Figure II.14. Molecular Sieve Packed Bed Tanks

- Figure II.15. Product Storage Tanks

- Figure II.16. A Typical Ethanol Load-Out Area

- Figure II.17. A Rotary Drum Dryer

- Figure II.18. A Ring Dryer Solids Recovery Cyclone

- Figure II.19. Transferring Co-Products in Load-Out Area

- Figure II.20. General Overview of the Corn Wet-Milling Process

- Figure II.21. Steep Tanks

- Figure II.22. Germ, Fiber, and Starch Separation During Corn Wet-Milling

- Figure II.23. Biochemical Conversion of Cellulosic Feedstocks

- Figure II.24. Chemical Process During Biochemical Conversion of Cellulosic Feedstocks

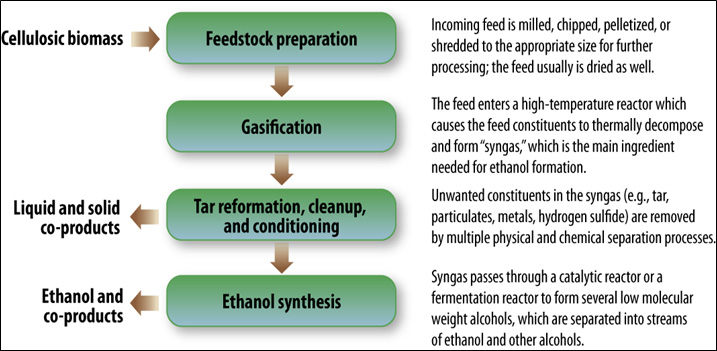

- Figure II.25. Thermochemical Conversion of Cellulosic Biomass to Ethanol and Co-products

- Figure II.26. Chemical Process During Thermochemical Conversion of Cellulosic Feedstocks

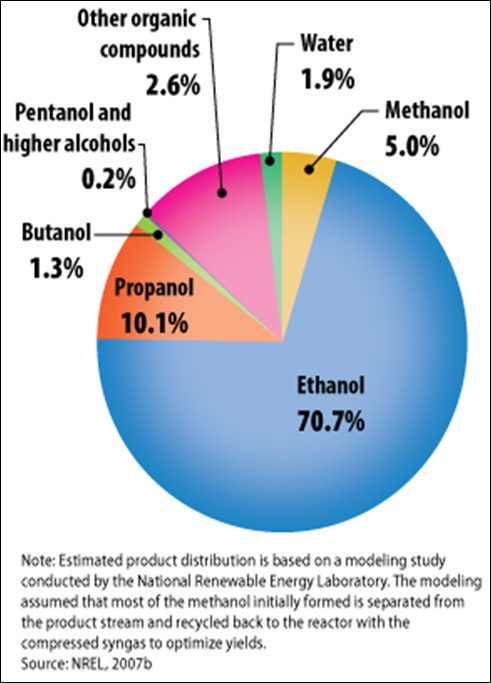

- Figure II.27. Estimated Mixed Alcohol Product Distributions for Thermochemical Conversion of Cellulosic Feedstock

- Figure II-5.1 Various Uses of Corn (EPA, 1995)

- Figure II-7.1 General Overview of the Corn Dry-Milling Process

- Figure II-8.1 Flow Diagram of Corn Dry-Milling Process

- Figure II-20.1 Simplified Flow Diagram of Corn Wet-Milling Process (Ramirez, 2008)

List of Tables

- Table II.1. Production Steps in Corn Dry-Milling

- Table II.2. Production Steps in Corn Wet-Milling

- Table II.3. Production Steps in Biochemical Conversion

- Table II.4. Production Steps in Thermochemical Conversion

- Table III.1. Examples of Hazardous Chemicals Found at Ethanol Manufacturing Facilities

Abbreviations

- AFEX

- ammonia fiber explosion

- ANPR

- Advanced Notice of Proposed Rulemaking

- ARRA

- American Recovery and Reinvestment Act

- Ca(OH)2

- calcium hydroxide

- CGF

- corn gluten feed

- CO

- carbon monoxide

- CO2

- carbon dioxide

- DD&E

- distillation, drying, and evaporation

- DDGS

- dried distillers' grain with solubles

- DOE

- United States Department of Energy

- EISA

- Energy Independence and Security Act

- E10

- ethanol/gasoline blend containing 10 percent ethanol

- E85

- ethanol/gasoline blend containing 85 percent ethanol

- E98

- ethanol/gasoline blend containing 98 percent ethanol

- HAZWOPER

- Hazardous Waste Operations and Emergency Response

- H2

- hydrogen gas

- H2S

- hydrogen sulfide

- H2SO4

- sulfuric acid

- HCS

- Hazard Communication Standard

- LFL

- lower flammable limit

- mg/m3

- milligrams per cubic meter

- mm

- millimeter

- MOC

- management of change

- MPa

- megapascals

- NEC

- National Electric Code

- NEP

- National Emphasis Program

- NFPA

- National Fire Protection Association

- PEL

- permissible exposure limit

- PHA

- process hazard analysis

- ppm

- parts per million

- POx

- partial oxidation

- PPE

- personal protective equipment

- psi

- pounds per square inch

- PSM

- Process Safety Management

- RFS2

- Renewable Fuels Standard, 2007 issue

- SDS

- Safety Data Sheet

- SO2

- sulfur dioxide

- SSF

- simultaneous saccharification and fermentation

- STEL

- short-term exposure limit

- TWA

- time-weighted average

- USDA

- United States Department of Agriculture

- WDGS

- wet distillers grain with solubles

- USCSB

- United States Chemical Safety and Hazard Investigation Board

I. Introduction

Ethanol is an organic chemical used in medical products, industrial solvents, alcoholic beverages, and many other applications. In recent years, ethanol has been used increasingly in motor vehicle fuels, and this particular use now dominates the demand for ethanol in the United States. The ethanol manufacturing industry has changed considerably and rapidly in response to this increased demand:

- Between 2000 and 2010, the number of ethanol manufacturing facilities in the U.S. nearly quadrupled.

- Over the same time frame, total nationwide ethanol production increased more than eight-fold. In 2010, U.S. facilities manufactured more than 13 billion gallons of ethanol, compared to just over 1.6 billion gallons in 2000.

- Corn is currently the primary feedstock for most ethanol production. However, to meet demands for alternative fuels, ongoing research and development is investigating how to manufacture ethanol from a much broader array of feedstocks.

As with any growing industry, it is important to ensure that health and safety management procedures keep up with the changing profile of the underlying manufacturing processes. This OSHA Technical Manual (OTM) chapter was prepared to educate readers about some of the safety and health hazards associated with the current and anticipated future production technologies for ethanol manufacturing facilities in the United States.

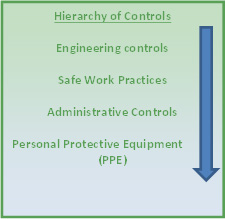

Information in this OTM chapter is organized as follows:

- Section II presents a profile of the U.S. ethanol manufacturing industry and describes the most commonly used production technologies, including information on emerging technologies.

- Section III identifies selected safety and health hazards associated with ethanol manufacturing.

- Section IV identifies some of the controls (engineering, administrative and personal protective equipment) typically used to prevent or mitigate these hazards.

- Section V outlines emergency planning requirements.

- Section VI discusses inspecting/investigating ethanol processing facilities.

- Appendix A summarizes hazards and controls discussed in this OTM chapter.

- Appendix B is a list of some OSHA standards relevant to workplace hazards in ethanol manufacturing facilities.

- Appendix C reviews safe entry requirements for aboveground storage tanks.

- Appendix D discusses various options for producing ethanol from cellulosic materials.

- Last are the references and glossary sections, respectively. The glossary is a list of definitions for all terms shown in bold.

The contents of this OTM chapter reflect conditions in the ethanol manufacturing industry at the time of its composition. It is likely that this industry will continue to change in the future, particularly as viable production technologies are developed for feedstocks other than corn. General information is presented on production processes likely to be found at most ethanol manufacturing facilities. However, process design and safety systems are expected to vary from one facility to the next. An extensive account of unit operations and safety and health hazards for ethanol manufacturing facilities is presented, but should not be viewed as a comprehensive compilation of the equipment and hazards that exist at every facility in this industry.

In addition to complying with the requirements of the Hazard Communication Standard (HCS; 29 CFR 1910.1200) when hazardous chemicals exist in the workplace, ethanol processing facilities must also be evaluated to determine if the requirements of the Process Safety Management of Highly Hazardous Chemicals standard (PSM; 29 CFR 1910.119(a)(1)(i) & (ii)) apply. PSM requirements must be implemented when a process involves a highly hazardous chemical at or above the specified threshold quantities, listed in Appendix A of the standard and/or involves 10,000 pounds or more of a flammable gas or liquid (e.g., ethanol, gasoline). However, there is an exemption (OSHA, 1997) for flammable liquids stored in atmospheric tanks or transferred and kept below their normal boiling point without the benefit of chilling or refrigeration. This exemption is applicable to flammable liquids in tanks, containers and pipes used only for storage and transfer. Similarly, stored flammable liquids in containers, including cans, barrels and drums are exempt from coverage by the PSM standard.

Process means any activity involving a highly hazardous chemical including any use, storage, manufacturing, handling, or on-site movement of such chemicals, or any combination of these activities. For purposes of this definition, any group of vessels which are interconnected and separate vessels which are located such that a highly hazardous chemical could be involved in a potential release, shall be considered a single process. Citations under 29 CFR 1910.119 will continue to be issued when the quantity of flammables in the process, not counting atmospheric storage, exceeds 10,000 pounds, or where the quantities in storage do not fall within the exception for other reasons (i.e., non-atmospheric storage, storage that relies on refrigeration, quantities in process and not actually in storage). 29 CFR 1910.119 Appendix C provides non-mandatory compliance guidelines and recommendations for PSM.

II. Ethanol Industry and Process Descriptions

A. Profile of the U.S. Ethanol Industry

Figure II.1. Ethanol Characteristics

Figure II.1. Ethanol Characteristics

Text version of Figure II.1.

Physical properties of C2H6O:

- Boiling point: 173°F

- Explosive limit in air: 3.3-19 in percent, by volume

- Clear, colorless liquid

- Weak and winelike odor

Ethanol or ethyl alcohol (Figure II.1), has three primary U.S. markets, the most recognized being the alcohol found in alcoholic beverages. Industrial applications are another major market, since ethanol is widely used as a formulation component or solvent in the manufacturing of pharmaceuticals, paints, personal care products, cleaning products, and flavorings. Finally, ethanol can be used as an automotive fuel or fuel additive, and this is by far the largest market for ethanol today. In the United States, ethanol is typically mixed with gasoline in a 10 percent ethanol blend (E10), but vehicle engines can be designed to run on blends of up to 85 percent ethanol (E85) or even pure ("neat") ethanol.

Historically, ethanol is produced in two different ways: as a fermentation product (i.e., bioethanol) or from the petroleum by-product ethylene (i.e., synthetic ethanol). Synthetic ethanol accounts for less than 10 percent of ethanol production and is used almost exclusively in industrial applications (ORNL, 2010). Bioethanol accounts for the vast majority of non-petroleum based ethanol production. Specifically, ethanol formed by fermentation of starch-based or cellulosic-based feedstock accounts for nearly all of today's ethanol market, with only minimal amounts currently manufactured via thermochemical production. However, this breakdown may change in the future, as further research is conducted on the viability of thermochemical production processes.

The U.S. ethanol industry has changed dramatically in recent years as it adjusts to increasing demand, emerging production technologies, and shifting government policy. This section characterizes the current state of the industry and highlights some of the issues influencing the future of the industry. The future profile of the U.S. ethanol industry may differ considerably from current conditions. Major growth in the U.S. ethanol industry within the last 10 years has propelled ethanol into a significant player in meeting America's demand for motor fuels. This growth has been spurred in part by interest in reducing reliance on costly, foreign, nonrenewable energy sources.

From 2000 to 2010, total U.S. ethanol production increased from 1.63 billion gallons a year to 13.3 billion gallons a year. U.S. corn-based ethanol production was 13.3 billion gallons in 2010, accounting for almost 40 percent of total U.S. corn use in the 2010 crop year. In the same period, ethanol was blended into over 90 percent of the nation's gasoline supply, replacing about 445 million barrels of imported oil. As gasoline prices rise, ethanol's appeal as a blend increases, as does the profitability of ethanol production, and the demand for corn (USDA, 2012). In 2013, ethanol (an estimated 13.3 billion gallons) accounted for 10 percent of U.S. gasoline supply; more than 98 percent of the ethanol production was made from corn (RFA, 2014). Corn used for ethanol generates co-products, for example, dried distillers grains with solubles (DDGS), which is sold as livestock feed (USDA, 2013). Due to the dominance of corn in the U.S. ethanol industry, II.B focuses on producing ethanol from corn.

From 2000 to 2011, the total number of ethanol production facilities rose from 54 facilities in 17 states to 204 facilities in 29 states. Thus, a large portion of the nation's ethanol manufacturing facilities were constructed in the last 10 years. As of January, 2014, the number of ethanol plants rose to 210 in 28 states. The vast majority of biorefineries are concentrated in the "corn belt", the top six ethanol producing states as of January 2011 were, in order, Iowa, Nebraska, Illinois, Minnesota, South Dakota, and Indiana. New construction is expanding to other areas of the country, with facilities underway in North Carolina, Georgia, and California (RFA, 2011a). As of December 2013, the top ten ethanol producing facilities were in North Dakota, South Dakota, Nebraska, Kansas, Minnesota, Iowa, Wisconsin, Illinois, Indiana and Ohio (not in order of production; RFA, 2014). Figure II.2. shows the locations of ethanol production facilities in the U.S. and Figure II.3 shows the growth rate in U.S. ethanol production.

Figure II.2. Map of Ethanol Production Facilities in the U.S. (USDA, 2013b)

Figure II.3. Growth in U.S. Ethanol Production 1980-2013 (RFA, 2014)

Text version of Figure II.2.

This figure shows a map of counties in the United States shaded different colors depending on how many bushels of corn are produced in the county.

Figure II.3. Growth in U.S. Ethanol Production 1980-2013 (RFA, 2014)

Text version of Figure II.3. Listed below are years of 1980-2013 and the corresponding amount of U.S. Ethanol Production (in millions of gallons):

- 1980

- 175

- 1981

- 215

- 1982

- 350

- 1983

- 415

- 1984

- 510

- 1985

- 617

- 1986

- 712

- 1987

- 819

- 1988

- 831

- 1989

- 843

- 1990

- 848

- 1991

- 866

- 1992

- 985

- 1993

- 1,154

- 1994

- 1,289

- 1995

- 1,358

- 1996

- 1,088

- 1997

- 1,288

- 1998

- 1,405

- 1999

- 1,465

- 2000

- 1,622

- 2001

- 1,765

- 2002

- 2,140

- 2003

- 2,810

- 2004

- 3,404

- 2005

- 3,904

- 2006

- 4,884

- 2007

- 6,521

- 2008

- 9,309

- 2009

- 10,938

- 2010

- 13,298

- 2011

- 13,929

- 2012

- 13,218

- 2013

- 13,300

Ethanol can be produced from a wide variety of feedstocks. Traditionally, ethanol is produced from materials rich in simple sugars or starches. These materials are broken down and fermented with yeast or other organisms to produce ethanol. The U.S. industry is dominated by corn, but other possible sugar and starch feedstocks include sugarcane, sugar beets, grain sorghum (milo), wheat, barley, and cheese whey.

Appendix D focuses on producing ethanol from cellulosic materials because of future expansion into this method of production by the ethanol industry. As of January 2014, five of the seven plants under construction or expansion will use cellulosic or waste feedstocks (RFA, 2014). More recently, the industry has been developing new methods to handle cellulosic feedstocks, which refer to materials where energy is stored as complex sugar polymers called cellulose. Cellulosic feedstocks include materials such as agricultural residues (e.g., corn stover, sugarcane bagasse), forestry waste, and municipal solid waste. Cellulosic ethanol can be produced similarly to sugar/starch ethanol, except that additional chemical pretreatments are required to break down the cellulose into simple sugars prior to fermentation. Alternatively, cellulosic material can undergo thermochemical processing where the feedstock is gasified and then converted to ethanol through catalysis or fermentation. Cellulosic technologies promise to substantially increase the quantity and types of feedstock available for ethanol production, as well as use materials that were previously viewed as waste products. However, some of these technologies are still in development and have not yet been realized at commercial scales.

Integrated biorefineries are envisioned as a key model for future ethanol production. Corn wet-milling facilities, described below, are one example of this model. Biorefineries utilize all of the components of a feedstock to produce multiple products, such as fuels, chemicals, animal feed, and power. By generating their own power, these facilities reduce costs and emissions, and the production of high-value chemicals and animal feeds increases profitability when compared to facilities that produce fuel alone (NREL, 2009). The government is investing heavily in biorefineries: in December 2009, the U.S. Department of Energy (DOE) and the U.S. Department of Agriculture (USDA) awarded $564 million in American Recovery and Reinvestment Act (ARRA) funding to 19 integrated biorefinery projects at pilot, demonstration, and commercial scales (DOE, 2009). The biorefinery approach is viewed as integral to the industry's development and economic success.

B. Producing Ethanol from Starch- and Sugar-Based Materials

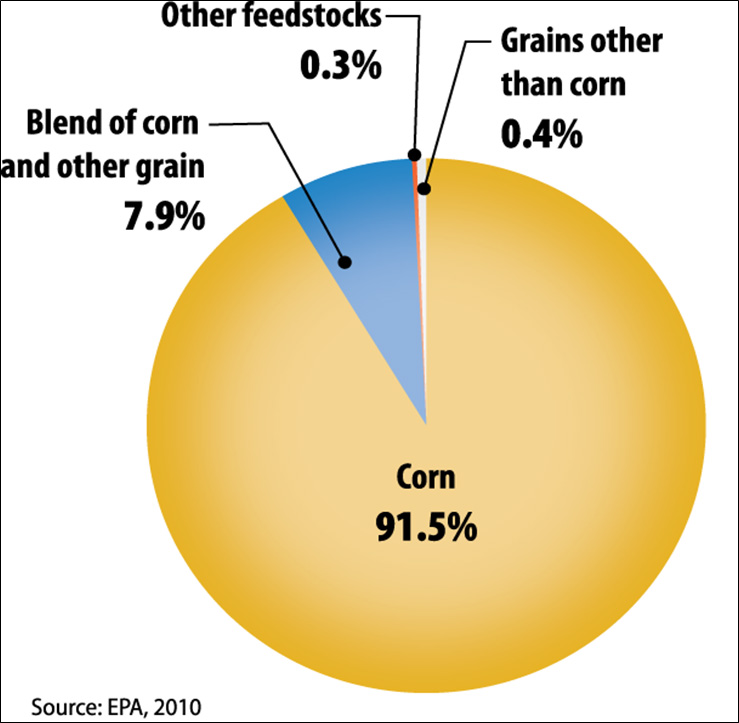

Figure II.4. Current Breakdown of Domestic Ethanol Manufacturing by Feedstock

Text version of Figure II.4.

- 91.5% - Corn

- 7.9% - Blend of corn and other grain

- 0.3% - Other feedstocks

- 0.4% - Grains other than corn

Current commercial production of ethanol is based almost exclusively on starch- and sugar-based feedstocks. As shown in Figure II.4, in the United States, the ethanol industry is dominated by corn, with 91.5 percent of production capacity from facilities using corn alone and another 7.9 percent of capacity from facilities using a blend of corn and other grain (e.g., corn and milo), with corn as the primary feedstock (EPA, 2010). Facilities using other grains (e.g., wheat, milo) without corn make up an additional 0.4 percent of capacity. The remaining U.S. production capacity (0.3 percent) comes from facilities processing other feedstocks, such as cheese whey (lactose fermentation), potato waste, and beverage or brewery waste.

Figure II.5. Image of a Corn Kernel showing the various components - starch, bran, starch and gluten, and germ.

While not yet in commercial use in the U.S., other feedstocks can also be utilized for ethanol production. Brazil, the world's second-largest producer of ethanol, used sugarcane to produce 6.9 billion gallons of ethanol in 2010 (RFA, 2011a).

In Europe, the most common feedstock is wheat, although other cereal based grains can be used (e.g., barley, maize, rye), two-thirds of all raw materials used are cereal grains, while the rest of the feedstock is mainly derived from sugar beets (ePURE, 2011).

Although the United States grows small amounts of sugarcane and sugar beets, these crops are used primarily in the sugar industry; because sugarcane is a tropical plant, in the United States it is grown primarily in Florida, Texas, Louisiana, and Hawaii. In contrast, sugar beets are harvested primarily in northern states, with production concentrated in Minnesota and North Dakota. A 2006 assessment found that domestic production of ethanol from sugarcane and sugar beets was not cost competitive at that time (USDA, 2006).

Figure II.5.1 Various Uses of Corn (EPA, 1995)

A corn kernel—or shelled corn (Figure II.5) —is sometimes viewed as consisting of three main structural elements, each of which contains a different subset of the kernel's nutrients (Figure II.5.1). The first element, the bran (or hull), includes the outer skin of the kernel and is high in fiber. The second element, the endosperm, makes up most of the volume of the corn kernel and contains protein-rich gluten and sugar-rich starch. The last element, the germ, is the embryo of the seed and is located inside the endosperm. The germ is small but oil-rich. By dry weight, shelled corn's nutritional makeup is dominated by starch (72 percent, dry weight). Figure II.6. illustrates the remaining nutritional constituents of corn. The high starch content makes corn a good feedstock for ethanol production, while its widespread cultivation in the United States makes it economically efficient. The challenge in corn ethanol production is to separate the starch from the other components of shelled corn, and then to convert the starch into ethanol.

Text version of Figure II.5.1.

This diagram shows varous parts of corn and what they can be used for.

- Endosperm

- Corn Meal

- Cereals

- Gluten

- Cattle Feed

- Raw Starch

- Edible Starch

- Corn Starch

- Jellies

- Candies

- Dextrin

- Mucilage

- Glue

- Textile Sizing

- Food Sauces

- Fireworks

- Industrial Starch

- Laundry Starch

- Textile Sizing Manufacture

- Filler in Paper

- Cosmetics

- Explosives

- Corn Syrup

- Mixed Table Syrups

- Candies

- Confectionery

- Ice Cream

- Shoe Polishes

- Corn Sugar

- Infant Feeding

- Diabetic Diet

- Caramel Coloring

- Vinegar

- Lactic Acid

- Tanning Mixtures

- Brewing

- Artificial Silk

- Edible Starch

- Hull

- Bran

- Cattle Feed

- Bran

- Germ

- Oil Cake (or Meal)

- Cattle Feed

- Crude Corn Oil

- Soap

- Glycerin

- Soluble Corn Oil

- Textile Sizing

- Cloth Coloring

- Refined Corn Oil

- Salad Oils

- Cooking Oils

- Medicinal Oils

- Plastic Resin

- Rubber Substitutes

- Erasers

- Elastic

- Heels

- Oil Cake (or Meal)

Figure II.6. Nutritional Makeup of Shelled Corn

Figure II.6. Nutritional Makeup of Shelled Corn

Text version of Figure II.6.

- 72% - Starch

- 9.5% - Fiber

- 9.5% - Protein

- 4.3% - Oils

- 2.6% - Simple Sugars

- 1.4% - Minerals

- 0.7% - Others

There are two main processes for producing ethanol from corn: dry-milling (II.B.1) and wet-milling (II.B.2). Both processes involve breaking down the starch in the corn kernel into simple sugars and then fermenting the sugars to create ethanol. The primary difference between the two methods is whether the entire kernel is processed, as in corn dry-milling; or if the corn kernel is first broken down into its individual components (i.e., germ, fiber, gluten, and starch) prior to processing, as in corn wet-milling. Dry mill ethanol plants generally produce only one primary co-product, distillers' grain with solubles (DGS), which can be sold wet (WDGS) or dried (DDGS) for use as animal feed. In contrast, the corn wet-milling process of separating shelled corn into its components, prior to processing, increases the number of co-products realized, usually gluten feed, gluten meal, food-grade corn oil, and DGS. There are currently far fewer wet milling facilities than dry milling facilities in the United States. Data available in November, 2009 indicated that there were 180 corn or starch ethanol plants operating in the U.S. 173 of these plants processed corn and/or other similar grains, and only 11 of these used the wet milling process (EPA, 2010).

-

Corn Dry-Milling

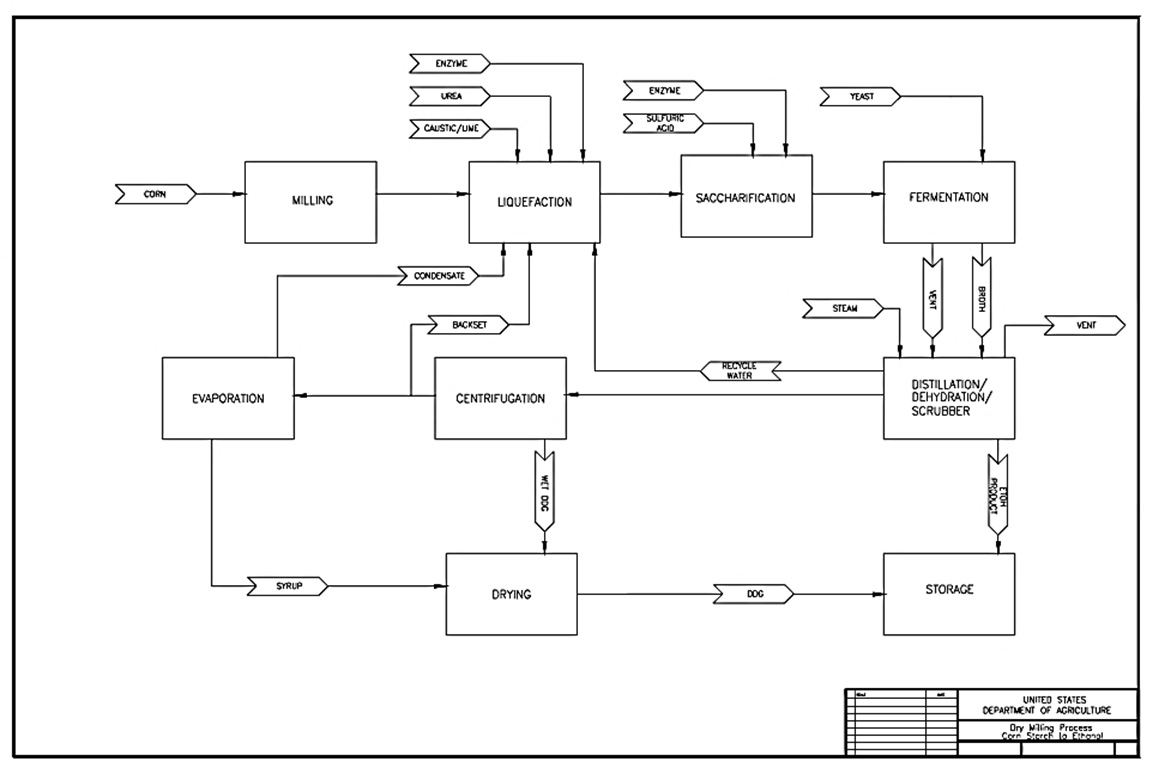

This section reviews the typical production steps found at ethanol manufacturing facilities that use the corn dry-milling process. Figure II.7 is an overview of the chemical processes that occur during corn dry-milling. The processing steps (Figure II.7.1, Figure II.8.1) are shown in the chronological order observed at these facilities. However, corn dry-milling facilities will not necessarily employ every one of these steps in the order shown, and some facilities may use different terminology when referring to these processing steps. Compare the steps of the corn dry-milling process in Figure II.8.1 with the corn wet-milling process in Figure II.20. Table II.1 summarizes each of the production steps, primary inputs, primary outputs and the main operations discussed.

This section is based on information from many references (e.g., BeMiller and Whistler, 2009; ICM, 2011; Jacques et al., 2003; Mosier and Ileleji, 2006; Rausch et al., 2005 and RFA, 2011b).

Figure II.7. Chemical Process in Corn Dry-Milling

Figure II.7.1 General Overview of the Corn Dry-Milling Process

Figure II.8.1 Flow Diagram of Corn Dry-Milling Process (NREL, 2000)

Text version of Figure II.7.

This chart shows an overview of chemical processes during corn dry-milling.

The chemical process begins with starch and water being added together. After enzymes are introduced, the combination becomes glucose. Adding yeast to the glucose results in ethanol and carbon dioxide.

The chemical equations for the steps are as follows: (C6H10O5)n + H2O becomes C6H12O6 after adding enzymes. After the yeast step, the result is 2C2H5OH + 2CO2.

As an example, these are example masses during the various steps: 100 lbs of starch plus 10 lbs of water becomes 105 lbs of glucose after the addition of enzymes. 53 lbs of ethanol and 51 lbs of carbon dioxide are the result after the addition of yeast.

Notes:

- The masses shown in the third row indicate anticipated quantities of intermediates and products assuming a 100-pound charge of starch and a 100 percent reaction yield. Actual yields at ethanol manufacturing facilities are considerably lower.

- lbs = pounds

- Adapted from Dale and Tyner, 2006

Text version of Figure II.7.1.

The chart begins with shelled corn going to the receipt, storage, and inspection stage. After that, the process goes to cleaning, then milling, followed by liquefaction, then saccharification, and fermentation. After the next step, distillation and dehydration, ethanol is formed, and the rest of the product goes to the co-product processing stage, after which it becomes animal feeds and other co-products.

The following are descriptions given after various stages of the chart:

- Receipt, storage, and inspection

- Large corn husks and forein material are removed from the incoming corn, and the kernels are stored for further processing.

- Cleaning

- Screeners or scalpers remove additional unwanted material (e.g., stones, glass, sticks) from the corn kernels.

- Milling

- Corn kernels are crushed and ground, forming a dry, fine corn flour.

- Liquefaction

- Corn flour, water, enzymes, and other ingredients are mixed in a tank, where corn starch breaks into simple sugars.

- Saccharification

- Another enzyme is added to break the simple sugars down further into glucose.

- Fermentation

- Yeast is added to the mixture to help convert glucose into ethanol and carbon dioxide.

- Distillation and dehydration

- The ethanol that is formed is separated from other constituents and purified to product specifications

- Co-product processing

- Products other than ethanol are further processed to meet end-user needs.

Text version of Figure II.8.1.

This diagram shows the steps that corn goes through in a Dry-Milling process.

NOTE: The table below is best viewed on a tablet device, notebook, or desktop computer.

Table II-1. Production Steps in Corn Dry-Milling

Production Steps Primary Inputs Primary Outputs Operations Performed Receipt, storage, and inspection

Shelled corn

Stored corn

- - Receive shelled corn by truck or rail

- - Unload corn into receiving pits

- - Transfer corn to storage bins or silos

- - Inspect corn upon receipt

Cleaning

Shelled corn from storage

Cleaned whole corn kernels

- - Pass corn through screeners or scalpers to remove oversized and smaller material

- - Pass corn through other steps (e.g., destoner, magnet) to remove other unwanted objects

Milling

Cleaned whole corn kernels

Fine corn flour

- - Transfer whole kernels to a hammer mill, impact mill, or other milling operation

- - Crush and grind shelled corn into a fine flour

Liquefaction

Fine corn flour

"Mash" (liquid mixture of corn flour and other corn parts)

- - Mix fine corn flour with water in large cook or slurry tanks

- - Add chemicals to adjust the slurry's pH

- - Add enzymes (alpha amylase) to solution to break down corn starch into dextrins

Saccharification

"Mash"

Mash with starch broken down into simple sugars

- - Add enzymes (glucoamylase) to mash to breakdown dextrins into glucose

Fermentation

Mash with starch broken down into simple sugars

"Beer" mixture containing ethanol and solids from grain and yeast; and carbon dioxide

- - Add yeast to convert glucose in mash into ethanol and carbon dioxide

- - Pump beer to separate storage vessel

Distillation and dehydration

"Beer" mixture (fermented mash)

Denatured ethanol

- - Pump beer mixture into a continuous distillation system, which may contain multiple columns

- - Collect purified ethanol from the vapor portion of columns and spent solids (stillage) from the bottom

- - Purify ethanol stream in rectifying column, molecular sieve, or other production equipment

- - Add denaturant to ethanol in cases where ethanol is not used for human consumption

- - Store denatured ethanol in tanks until distribution

Co-product processing

Stillage from distillation columns

Wet distillers' grain and/or dried distillers' grain with solubles (DDGS)

- - Reduce moisture content in stillage by using centrifuges, dryers, or other equipment

- - Make selected co-products by mixing varying quantities of dry products with other materials

- - Load dry products into trucks, railcars, or other means of transport for distribution

-

Receipt, storage and inspection

Corn dry-milling facilities typically receive corn kernels or shelled corn by truck or rail from farms. The shelled corn is separated from husks and other unwanted material during harvesting, though some of this material is still present in the shelled corn shipments that arrive at ethanol manufacturing facilities. The shelled corn shipments arriving at manufacturing facilities typically have moisture contents of 15 percent or less, which helps prevent heating and microbial mold activity in the grain.At ethanol manufacturing facilities, incoming shelled corn is dumped from trucks or railcars into receiving pits – typically grated chutes (Figure II.8) in designated unloading areas. The kernels fall through the grates and typically onto a conveying system which takes the kernels to a storage area. At most facilities, a bucket elevator lifts the shelled corn to the top of large storage bins or silos (Figure II.9). It is not uncommon to encounter concrete silos that are more than 100 feet tall. A bucket elevator is designed for the vertical transport of materials. The elevator consists of a series of buckets attached to a continuous, rotating belt driven by a motor, and the entire system is usually enclosed. The buckets pick up material at the bottom of the elevator and empty the same material at the top of the elevator via the movement of the belt. Storage bins and silos are filled from the top (by bucket elevator) and emptied from the bottom so that the oldest material is continually emptied, thus ensuring that shelled corn does not remain in the silos for unacceptably long time frames. Facilities typically keep enough stored corn on hand so that production could continue for several days in the event that scheduled deliveries are interrupted.

Upon receipt in storage bins or silos, the corn is inspected for quality. Typically, milling facilities use U.S. No. 2 grade yellow dent corn, which has specifications for weight, damaged kernels, and foreign material (Corn Refiners Association, 2011; USDA, 2013a). Facilities may also perform quality assurance testing to check for infestations or fungal toxins (e.g., aflatoxin, which is a by-product of mold).

Figure II.8. Corn Dumped into Receiving Pits

Figure II.9. Bucket Elevator and Storage Silo

-

Figure II.10. Corn Cleaning Unit Operation

Cleaning

The corn kernels must be cleaned prior to processing. The incoming stream of corn kernels, as received, is typically passed through a screener or scalper (Figure II.10.), or multiple screeners or scalpers arranged to remove oversized materials (e.g., corn cobs, husks, sticks) and smaller materials. The unwanted materials tend to account for a very small portion of the incoming corn stream. Cleaning operations, which are typically operated continuously but can also be operated in batches, involve passing the shelled corn over multiple vibrating, perforated sheets, with different sized holes on each sheet. The screeners are sized so that corn kernels can pass through some sheets, thereby removing oversized materials, but do not pass through others, thereby removing undersized materials. Ultimately, only materials of a certain size range (i.e., a standard corn kernel) will make it through the screening process. The corn may also pass through a destoner, which separates objects based on weight and can be used to remove heavier objects (e.g., stones, glass) from the process stream. During the cleaning process, pressurized air may be used to remove chaff and dust. In addition, the process stream will usually pass through a magnetic separator to remove any tramp metal that may be remaining. The principal output from the cleaning operation is a "dry" process stream of shelled corn. -

Figure II.11. A Typical Corn Milling Device

Milling

Once the corn has been cleaned, the whole kernels are conveyed to a milling operation (Figure II.11), typically a hammer mill or impact mill that breaks down the hard exterior of the shelled corn to expose the starch that was previously encapsulated in it. This makes the starch in the milled corn flour more suitable for further processing at the next step, liquefaction. Milling processes typically crush and grind shelled corn into a fine flour. In a hammer mill, for example, a series of hammers are mounted on a rotating drum. The drum rotates at a high speed, and the incoming kernels are shattered by the impact of hammers, other particles, and the walls of the hammer mill. Size-selective screens allow milled corn flour to exit the mill while retaining larger particles requiring further size reduction. Typical screens are sized between 0.13 and 0.2 inches in diameter (3.2 and 4.8 millimeter (mm) in diameter). The output from milling operations is a "dry" fine corn flour that can be readily mixed with water, whereas shelled corn cannot. -

Liquefaction

The previous three production steps involved a "dry" process stream. In the liquefaction step, the milled corn flour is poured into water, thus entering a "wet" process stream for the remainder of the ethanol manufacturing operations. The primary functions of the liquefaction step are to generate a slurry suitable for further processing and to begin breaking down the corn starch into simpler sugars.In liquefaction, the fine corn flour is mixed with water in large cookers (e.g., a steam injection heater called a jet-cooker) or slurry tanks. Facilities will also add alpha-amylase, an enzyme, to the solution. Alpha-amylase helps break down the corn starch into shorter carbohydrate chains known as dextrins. The most effective use of alpha-amylase occurs when the pH of the slurry is between 6.0 and 6.5, and the pH is kept in this range from the time the alpha-amylase is added until liquefaction is complete. Anhydrous ammonia (refer to 29 CFR 1910.119 Appendix A for PSM applicability), used caustic from the cleaning system, and various other bases (e.g., lime) may be added if the pH falls below the optimal range, whereas sulfuric acid might be added if the pH starts to exceed the optimal range. Other chemicals (e.g., urea) may be added at some facilities to optimize enzymatic activity (NREL, 2000). The vessel temperature is also adjusted throughout the liquefaction cycle to optimize the enzymatic breakdown of starches, with temperatures ranging anywhere from 180°F to 220°F. Hot condensate water from other production areas is used to achieve this temperature range. The liquefaction process can take several hours.

To ensure a relatively steady flow of product, facilities with corn dry-milling operations will often operate multiple liquefaction vessels in parallel. Overall, the cooking process that occurs during liquefaction uses physical processes (heat and high-shear mixing) to further break apart the starch granules so that the alpha-amylase can access the starch polymers to break them down biochemically. At the end of this process, all the starch should have been converted to dextrins. The liquefied slurry is a yellow, watery mixture of corn solubles and insolubles called "mash." In the next step, saccharification, the dextrins will be broken down into glucose.

-

Saccharification

At the end of liquefaction, the mash is cooled to 86°F and the enzyme glucoamylase is added as the mash is being pumped into fermentation tanks. Glucoamylase breaks down the dextrins into glucose, which completes the breakdown of the starch into simple sugars. The most effective use of glucoamylase occurs when the solution pH is between 4.0 and 5.5, which is considerably lower than the pH in the liquefaction process. Therefore, the solution pH must be lowered to achieve optimal enzymatic activity. The pH reduction at this stage is typically accomplished by blending in a lower pH stillage solution generated later in the process or by adding sulfuric acid. Saccharification usually occurs as the mash is filling the fermentation tanks and continues throughout fermentation in a process known as simultaneous saccharification and fermentation (SSF). -

Fermentation

Fermentation is the step that produces ethanol; it occurs in large fermentation tanks (Figure II.12). In addition to the mash and glucoamylase, yeast is added to the tanks in proper quantities to convert the glucose in the mash into ethanol and carbon dioxide (CO2). Fermentation lasts for 40 to 60 hours and during this time the mixture is agitated to ensure that the yeast and sugars remain well mixed. The purpose of this step is to biochemically convert as much of the glucose in the mash as possible to ethanol.Figure II.12. Ethanol Fermentation Tanks.

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Spill containment mechanism must be installed.

Unlike the upstream processes (e.g., milling, liquefaction, saccharification) that operate continuously, fermentation typically operates as a batch process. Most facilities have numerous tanks dedicated to fermentation and they typically operate in groups of three: while one tank is being filled, another is fermenting, and the third is emptying and made ready for filling. With this arrangement, upstream production never needs to halt between batches. Larger facilities can have multiple groupings of three tanks.

At the end of a fermentation batch, the vessel contains a mixture known as "beer," which is a complex mixture containing yeast, bran, gluten, and liquids. Ideally, the beer should contain very little, if any, glucose because the purpose of fermentation is to convert all glucose to ethanol. The liquid phase of the beer is typically 8 to 12 percent ethanol by weight. Facilities will pump the beer into a beer well, which serves as a reservoir of material for the subsequent downstream processes.

CO2 produced during fermentation is handled differently from one facility to the next. Some facilities collect the gas and sell it, typically to off-site vendors (e.g., for beverage carbonation). Other facilities will vent the gas to the atmosphere, particularly when no buyers are available. However, facilities will generally include scrubbers and other devices to ensure that any ethanol vapor in the CO2 exhaust is captured and returned to the process.

-

Distillation and Dehydration

After fermentation is completed, the next step is to separate and purify the ethanol from other beer constituents. The beer is pumped through a continuous, multicolumn distillation system. Distillation takes advantage of the fact that different liquids have different boiling points: while water boils at 212 degrees Fahrenheit (°F), ethanol boils at approximately 173°F. The temperature in the column will vary from approximately 212°F in the base (almost pure water at modest pressure) to about 172°F at the top, where an ethanol-water solution is recovered as an azeotrope. The boiling point of the mixture is lower than the boiling point of either ethanol or water, although very close to that of ethanol. Thus, when the ethanol-water mixture is heated, the vapors generated contain a greater percentage of ethanol than water. To purify the ethanol, the process is repeated multiple times in series, inside distillation columns. After each distillation step (or contacting step) in the columns, the vapors contain a higher percentage of ethanol.Figure II.13. Ethanol Distillation Columns.

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Spill containment mechanism must be installed.

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Spill containment mechanism must be installed.Most corn dry-milling facilities have at least two types of distillation columns (Figure II.13): beer columns and rectifying columns. The beer column generally separates the liquids (water and ethanol) from the spent solids (whole stillage). By heating the column, liquids in the beer evaporate and ethanol-containing vapors are collected at the top of the column, while the stillage is drained from the bottom. The vapors collected from the first column are then condensed and sent to the rectifying column. Again, the liquid is heated, and the ethanol-rich vapors are collected at the top of the column. Vapors collected from the rectifying column are approximately 91 to 95 percent ethanol. Water from the bottom of the rectifying column is diverted to a side stripper to extract the remaining ethanol. The side stripper works on the same principle as the distillation columns and continues to extract purified ethanol based on the 173°F boiling point. Water from the side stripper is recycled back to the cook process.

Figure II.14. Molecular Sieve Packed Bed Tanks

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Spill containment mechanism is not visible.

At this point, the purified ethanol still contains approximately 5 percent water. However, ethanol used for fuel must be anhydrous (i.e., waterless) to be blended with gasoline. To remove the remaining water, the ethanol-water azeotrope is typically passed through a molecular sieve to adsorb water from the mixture. The molecular sieve is a bed of specialized beads that selectively adsorb water based on molecule size (Figure II.14). The beads are commonly made from zeolite, a type of aluminosilicate. Similar to fermentation tanks, facilities typically operate multiple molecular sieves so that when one sieve needs to be regenerated (removal of the adsorbate (water)) after it becomes saturated with water another is always available to handle the ethanol stream. Ethanol exiting the molecular sieve is over 99 percent pure.

The final step in production is denaturing the ethanol. The purpose of denaturing is to intentionally put additives in the ethanol that render it unusable for human consumption, which makes the manufactured ethanol exempt from the beverage tax. At facilities that manufacture ethanol for fuels, the ethanol is denatured with conventional gasoline (5 percent by volume) prior to storage. The denatured ethanol is stored in tanks (Figure II.15) until distribution via tanker truck or rail to large terminals for further fuel blending and storage (Figure II.16).

Figure II.15. Product Storage Tanks

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required.

Figure II.16. A Typical Ethanol Load-Out Area

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required on rooftop storage tanks; transportation vehicles must also have the required labels/markings. Spill containment mechanism must be installed.

-

Co-Product Processing

The stillage from the distillation columns is centrifuged to separate the liquid from the solids. The solids, known as wet cake or distillers' grain, are made up of the remaining non-starch components of the corn kernels (e.g., bran, gluten) and added yeast. The wet cake collected from the distillation columns and centrifuge initially contains about 65 percent moisture. The liquid, known as thin stillage, is water containing 5 to 10 percent solids. The thin stillage is either diverted back to the cook process as makeup water or is sent to an evaporator and concentrated into syrup containing 25 to 50 percent solids (condensed distillers' solubles).The syrup is mixed back into the wet cake or distillers' grain to form what is commonly referred to as wet distillers' grain. Wet distillers' grain is a viable co-product, but has poor flow properties that make it difficult to handle. As a result, wet distillers' grain is often dried to 10 percent moisture. This can be done in a rotary drum dryer (Figure II.17) or in a ring dryer (Figure II.18) to form dried distillers' grain with solubles (DDGS). Dryer temperatures can vary considerably (e.g., from 220°F to 380°F) depending on many factors, such as the type of dryer used, the dryer residence time and feed rate, and the target moisture content. DDGS has the advantage of being more readily handled and transported, but the necessary drying step makes it more expensive to produce. Wet distillers' grain and DDGS are both sold as high-quality, high-protein animal feed products. These products are typically shipped to customers via railcar or truck at the facility's product load-out area (Figure II.19).

Figure II.17. A Rotary Drum Dryer

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Improper installation of explosion vent panel near work platform.

Figure II.18. A Ring Dryer and Solids Recovery Cyclone

Figure II.19a. Transferring Co-Products in Load-Out Area

Figure II.19b. Transferring Co-Products in Load-Out Area

-

Corn Wet-Milling

Corn wet-milling shares many of the same processes with corn dry-milling. The main difference is the addition of several steps at the beginning of the process that separate the corn kernel into its components. More co-products are typically created because of the corn kernel fractionation. Compare the steps of the corn wet-milling process in Figure II.20. and Figure II.20.1 with the steps of the corn dry-milling process in Figure II.7.1 and Figure II.8.1. Figure II.20.1 is a simplified flow diagram of the corn wet-milling process showing only the processing steps from the cleaning of the corn to the separation of the kernel into its component parts (germ, fiber, protein and starch; II.B.).Table II.2. summarizes each of the production steps, primary inputs, primary outputs, and main operations discussed in this section. While this section documents the common processing steps for corn wet-milling facilities, every facility differs: some facilities might not employ every step shown in this section, and other facilities might use different terminology when referring to these processing steps. This section is based on information from many references (e.g., Corn Refiners Association, 2011; Davis, 2001; EPA, 1995, 2010; and Galitsky et al., 2003).

Figure II.20. General Overview of the Corn Wet-Milling Process

Figure II.20.1 Simplified Flow Diagram of Corn Wet-Milling Process (Ramirez, 2008)

Figure II.20. Simplified Flow Diagram of Corn Wet-Milling Process

Text version of Figure II.20. Simplified Flow Diagram of Corn Wet-Milling Process.

The chart starts with shelled corn going to receipt, storage, inspection, and cleaning. From that step, it moves to steeping, then germ separation, followed by fiber separation, and finally starch separation. After starch separation, the two independent resulting steps are saccharification, fermentation, distillation, and dehydration, and co-product processing. Saccharification, fermentation, distillation, and dehydration results in ethanol, and the final products after co-product processing are animal feeds and other co-products.

The following are descriptions given after various stages of the chart:

- Receipt, storage, inspection, and cleaning

- Corn kernels are first stored in silos and other vessels and then are passed through screeners or scalpers to remove unwanted material (e.g., stones, glass, sticks).

- Steeping

- Corn kernels are added to large tanks of water containing sulfur dioxide; this softens the kernels and begins to separate their constituents.

- Germ separation

- Mills coarsely grind the softened corn kernels in order to separate the oil-rich germ from the steeped kernels.

- Fiber separation

- Mills further grind the mixture and screens help separate the bran-rich fiber from the starch and gluten.

- Starch separation

- Centrifuges and other processes separate the starch from the gluten.

- Saccharification, fermentation, distillation, and dehydration

- Enzymes and yeast are added to break the starch into simple sugars and eventually to convert glucose into ethanol and carbon dioxide.

- Co-product processing

- Products other than ethanol are further processed to meet end-user needs.

NOTE: The table below is best viewed on a tablet device, notebook, or desktop computer.

Table II-2. Production Steps in Corn Wet-Milling Production Steps Primary Inputs Primary Outputs Operations Performed Receipt, storage, and inspection

Shelled corn

Stored corn

- - Receive shelled corn by truck, rail, or grain elevators

- - Move shelled corn from truck or railcar into receiving pits and transfer it to storage area

- - Transfer corn in bucket elevators to storage bins or silos

- - Inspect corn upon receipt

Cleaning

Shelled corn from storage

Cleaned whole corn kernels

- - Pass corn through screener(s) or scalper(s) to remove oversized and smaller material

- - Pass corn through other steps (e.g., destoner)

- - Use pressurized air to remove chaff and dust

Steeping

Cleaned whole corn kernels

- Steeped corn kernels

- Spent steepwater

- - Add corn kernels to water tanks with sulfur dioxide and soak them for 28 to 48 hours

- - Empty tank and recharge it with fresh corn

- - Add fresh liquid to longest steeping tank

- - Recycle excess water

Germ separation

Steeped corn kernels

- Germ

- Fiber, starch, and gluten slurry

- - Grind steeped corn kernels into slurry

- - Separate oil-rich germ from steeped kernels (i.e., fiber, starch, and gluten slurry)

- - Wash extracted germ repeatedly to remove starch and gluten from mixture

Fiber separation

Fiber, starch, and gluten slurry

- Fiber

- Starch and gluten mixture (mill starch)

- - Pump fiber, starch, and gluten to impact mill for grinding to remove bran-rich fiber from starch and gluten

- - Separate fiber from gluten and starch using fixed, concave screens

- - Wash and screen fiber again to remove additional starch and gluten

Starch separation

Mill starch

- Starch (suspension)

- Gluten

- - Pump mill starch to centrifuge to separate gluten

- - Wash starch 8 to 14 times in water and hydroclones to remove remaining gluten

Saccharification, fermentation, distillation, and dehydration

Starch suspension

Denatured ethanol

- - Treat starch suspension with acid and enzymes to break down starch into dextrins and then into glucose

- - Add yeast to convert glucose into ethanol

- - Distill ethanol

- - Remove remaining water with molecular sieve

- - Add denaturant to ethanol

Co-product processing

- Spent steepwater

- Germ

- Gluten

- Starch

- Animal feed products

- Oils, starches, and syrups

- - Reduce moisture content in steepwater and starch suspension using centrifuges, dryers, or other equipment

- - Generate selected co-products by mixing varying quantities of dry products with other materials

- - Load dry products into trucks, railcars, or other packaging for distribution into commerce

-

Receipt, Storage, Inspection and Cleaning

This process is the same as that described for corn dry-milling (II.B.1.i. and II.B.1.ii). -

Steeping

The purpose of steeping is to soften the corn kernels for subsequent processing. The kernels are added to large tanks of water (Figure II.21), held at 125°F and contain approximately 0.1 percent sulfur dioxide (SO2). For the SO2-treated process water, a pH range of 4.0 to 5.0 is optimal to prevent microorganism growth and to facilitate separation of starch and proteins. As the corn soaks for 28 to 48 hours, the kernels increase in moisture content from 15 to 45 percent and approximately double in size. The kernels soften and the acidity of the steepwater helps to release some of the gluten and starch.Figure II.21. Steep Tanks

Note: Appropriate labels/markings (e.g., HazCom (29 CFR 1910.1200), confined space warning sign (29 CFR 1910.146)) must be displayed as required. Spill containment mechanism must be installed.

Steeping is often operated as a "continuous-batch" process, so that multiple steep tanks are connected in series and operated by the counterflow principle. When one tank of corn has finished steeping, the tank is emptied and it is refilled with fresh corn. Fresh liquid is added, not to the tank with the fresh corn, but rather to the steep tank that has been steeping the longest. The excess water from that tank is recycled back through the series of steep tanks (in order of descending steep time) until finally the liquid reaches the steep tank with fresh corn. This approach minimizes the water used by the process, reducing operating costs.

The principal outputs of this step are steeped corn kernels and spent steepwater. The sequence of processing steps for the steeped corn kernels are discussed in II.B.1.iii and II.B.1.iv, and further processing of the steepwater is described in II.B.2.v.

-

Germ, Fiber, and Starch Separation

Steeped corn kernels are sent through degerminating mills which tear the kernels apart to free the germ and about half of the starch and gluten. The resultant slurry is pumped through hydrocyclones to extract the germ from the mixture of fiber, starch, and gluten (EPA, 1995). The purpose of this step is to separate the oil-rich germ from the rest of the steeped kernels, which is essentially a mixture of fiber, starch, and gluten. This separation is performed because the germ does not contain the starch that is needed to produce ethanol. The extracted germ is washed repeatedly to remove any starch and gluten from the mixture. The germ is further processed into co-products II.B.2.v.The fiber, starch, and gluten slurry is pumped to an impact mill, where further grinding completely frees the bran-rich fiber from the starch and gluten. The fiber is then physically separated from the gluten and starch using a series of fixed, concave screens. The collected fiber is washed with water and screened again to remove any additional starch and gluten. Processing of the fiber is discussed in II.B.2.v. The remaining starch and gluten mixture is known as mill starch.

Figure II.22. Germ, Fiber, and Starch Separation During Corn Wet-Milling

Text version of Figure II.22. Germ, Fiber, and Starch Separation During Corn Wet-Milling.

Various production processes, intermediates, and co-products are listed in this flowchart.

The chart starts with steeped corn in the production processes category. From here, it moves on to germ separation, and can go further onwards to fiber separation and starch separation in the production processes category.

From germ separation, in addition to fiber separation, the germ is a resulting intermediate. From germ, the co-products of corn oil and feed products are the final steps.

The intermediate of the fiber separation step is fiber. This fiber can become a resulting co-product in the form of feed products.

Starch separation produces the intermediates of gluten and starch. Gluten can be a feed product, and various starches are co-products on their own, but can also be used in ethanol production.

The mill starch is pumped to a centrifuge where the low-density gluten is spun out of the mixture, leaving a starch-rich stream ready for further processing. II.B.2.v describes how facilities typically handle the gluten. The starch is washed 8 to 14 times in water, re-diluted, and passed through hydrocyclones to completely remove any remaining gluten. The starch is over 99.5 percent pure at this point and can be used to produce ethanol; the starch can also be used to manufacture various other products, including pure corn starch and corn syrups (described in II.B.2.v). Some corn wet-milling facilities are designed to manufacture multiple products from the starch, while others will manufacture just a single product. Figure II.22. illustrates the process of germ, fiber, and starch separation during corn wet-milling.

-

Saccharification, Fermentation, Distillation, and Dehydration

At this point, the wet milling process proceeds similarly to the dry milling process. Detailed descriptions of each of these process steps, including the chemicals and microorganisms that are typically added are discussed in II.B.1.iv to II.B.1.viii. The starch suspension is treated with acid and enzymes to break down the starch into dextrins, which are further broken down into glucose. Yeast fermentation then converts the glucose into ethanol. The ethanol is distilled to concentrate the alcohol content, remaining water is removed via molecular sieve, and the product is denatured prior to shipment. -

Co-product Processing

The major co-products from corn wet-milling include: animal feed products, corn oil, ordinary and modified starches, and corn syrups and sugars (Figure II.5.1). The exact combination of co-products will vary from one manufacturing facility to the next and each facility will tailor the range of co-products it produces to current market demands. Every U.S. ethanol-producing wet milling facility produces starches and corn gluten feed or meal; and most, but not all, of these facilities produce corn syrups in addition to ethanol. Most corn wet-milling facilities in the United States will have some of the following operations to process co-products:- The water drawn off the steeping process, known as light steepwater, contains approximately 6 percent of the original dry weight of the grain, of which 35 to 40 percent is protein. At most facilities, the light steepwater is sent to an evaporator where it is concentrated to 30 to 55 percent solids. The concentrated steeping liquor is then added to the fibrous milling residue produced by fiber separation. After the fiber has been screened and washed, it is sent through a drying operation. The steep liquor is blended with the dried fiber to form wet corn gluten feed (CGF). CGF can be sold wet or it can be dried first to extend its shelf life. CGF is widely used by farmers to feed dairy and beef cattle, swine, and poultry.

- The extracted germ is routinely processed for corn oil. The oil is extracted from the germ using a combination of mechanical (i.e., washing, dewatering, drying) and proprietary solvent-based extraction processes and is then refined. The remaining germ residue, or germ meal, is used as a component of animal feed. It is sometimes blended with CGF and is valued for use in poultry and swine diets.

- The extracted gluten is a protein-rich stream that is oftentimes dried and sold as another type of animal feed (corn gluten meal). Corn gluten meal contains about 60 percent protein compared to approximately 20 percent protein in CGF. Corn gluten meal is often used in poultry feed formulations.

- Finally, in addition to being converted to ethanol, the starch component of the corn kernel can be used to manufacture other starch or sweetener products. To produce ordinary starch, the starch suspension is dewatered mechanically (by vacuum filters or centrifuge) and thermally (by drier). To produce modified starches, such as acid-modified or oxidized starches, the starch suspension is treated with chemicals (e.g., hydrochloric acid, sodium hypochlorite) prior to dewatering. Alternatively, to produce sweeteners, the starch is broken down with acids and enzymes to form various syrups with different mixtures of sugars and levels of sweetness. The syrup is refined and then concentrated in evaporators. Some syrup is crystallized to form solid sugars.

- Receipt, storage, inspection, and cleaning

III. Ethanol Manufacturing Health and Safety Hazards

The principal hazards in ethanol manufacturing are associated with processing dry feedstocks and handling ethanol; therefore, ethanol manufacturing facilities combine some of the attributes of grain handling facilities and chemical processing facilities. Individually, these two types of facilities are accompanied by distinct hazards, but when they are combined, hazards associated with both grain handling and flammable liquid processing, storage, and transport come into play (RFA, 2007). Sources of information on past incidents in the ethanol industry include: OSHA IMIS accident investigation summaries, the media, and trade association publications (e.g., Jessen, 2011a).

While individual ethanol manufacturing facilities vary in terms of layout and their sequence of operations, safety and health hazards at these facilities typically occur in various production areas common to most facilities, such as the feedstock receiving area, process buildings where feedstocks are prepared for processing, the ethanol bulk storage area, and the ethanol load-out area (IAFC, 2008).

The remainder of this section provides an overview of some of the common types of hazards found at ethanol manufacturing facilities. Section IV discusses some of the preventive measures that may be implemented to assure workers' safety. Preventive measures in OSHA's PSM standard (29 CFR 1910.119) apply when a process involves a chemical at or above the specified threshold quantities, listed in Appendix A of the PSM standard and/or involves 10,000 pounds or more of a flammable gas or liquid, if the exemption discussed in Section I does not apply.

A. Flammable Liquids

Two Employees are Burned in Distillery Explosion

On September 13, 2002, Employees #1 and #2 were working in the vicinity of the A-still [where initial distillation took place] when it was started. One of the manhole covers in the absorption column was apparently open and flammable alcohol vapors escaped and exploded. Employees #1 and #2 both sustained burns and were hospitalized. The absorption column had been previously opened to inspect the corn grits process and apparently one of the manholes had not been closed. No lockout and tagout procedures (IV.U) were used when the absorption column was opened, and there was no verification process in place to ensure that all the manhole covers were closed before the still was activated.

(Modified for clarity)

Large ethanol manufacturing facilities produce more than 100 million gallons of ethanol each year and store large quantities of the chemical on site at any given time; because ethanol is flammable, the production and storage quantities have the potential to cause catastrophic fires and explosions. Ethanol manufacturing facilities typically take numerous precautions to prevent ethanol fires (IV.A; IV.B), which are perhaps the most well-known occupational hazard for this industry. They must also ensure compliance with emergency planning requirements (Section V).

In addition to ethanol, these facilities process and handle many other hazardous chemicals (III.F), but usually in much lower quantities. Table III.1. below lists some chemicals that are commonly found at ethanol manufacturing facilities. One example is the gasoline (which also contains benzene, 29 CFR 1910.1028; 29 CFR 1926.1128) that is added to ethanol as a denaturant. While gasoline and many other substances in the table exhibit their own hazardous properties, the total amount of gasoline used at these facilities is minimal in comparison to the quantities of ethanol.

| Chemical | Associated Type of Production | Associated Process at Facility | |||

|---|---|---|---|---|---|

|

Corn Dry-Milling |

Corn Wet-Milling |

Biochemical Conversion |

Thermochemical Conversion |

||

|

Alcohols other than ethanol |

|

|

|

May be found at all kinds of facilities, but primarily produced during catalysis of syngas at thermochemical conversion facilities. |

|

|

Ammonia |

Used for various purposes, such as to adjust solution pH, as a nutrient for yeast and other beneficial microorganisms, and for pretreatment in thermochemical conversion. |

||||

|

Carbon dioxide |

|

Formed as a by-product in all fermentation processes and either captured for further processing or vented to the atmosphere. Used in some pretreatment processes for biochemical conversion of cellulose. |

|||

|

Ethanol |

Formed in fermentation tanks and thermochemical conversion reactors, separated from water and other chemicals in multiple unit operations, and kept in storage tanks. |

||||

|

Gasoline |

Added to ethanol product in storage tanks. Benzene is an important hazardous constituent of gasoline (29 CFR 1910.1028; 29 CFR 1926.1128). |

||||

|

Hydrochloric acid |

|

|

|

Used to treat starch suspension to produce modified starches and sweeteners. |

|

|

Sodium hydroxide |

|

|

Used in fermentation tanks for pH control and as a yeast nutrient |

||

|

Sulfur dioxide |

|

|

Added to large tanks of water for steeping corn kernels, and used to treat starch suspension to produce modified sweeteners. |

||

|

Sulfuric acid |

|

Used to control bacteria; added to slurry mixtures to separate corn into starch, germ, fiber, and protein; and used during steam explosion or acid hydrolysis. |

|||

|

Syngas |

|

|

|

Primary product from process in gasification reactor and used to form ethanol in catalytic reactors. |

|

Note: This table presents a partial list of raw materials, intermediates, and products that may be encountered at ethanol manufacturing facilities. However, individual facilities are different, and they can use different chemicals and chemical combinations in their production processes. The table was adapted from Weston Solutions, Inc., 2008 and Section A; and the table does not consider typical process emissions.

Both OSHA and the National Fire Protection Association (NFPA) have classified ethanol as a flammable liquid (29 CFR 1910.106; NFPA 30). Ethanol meets the criteria for a Category 2 flammable liquid, according to OSHA's Flammable Liquids standard and the HCS (29 CFR 1910.106; 29 CFR 1910.1200 Appendix B). This is because ethanol ignites at normal room temperatures, has a flash point of 55°F, and has a boiling point of 173°F (OSHA/EPA, 2011).

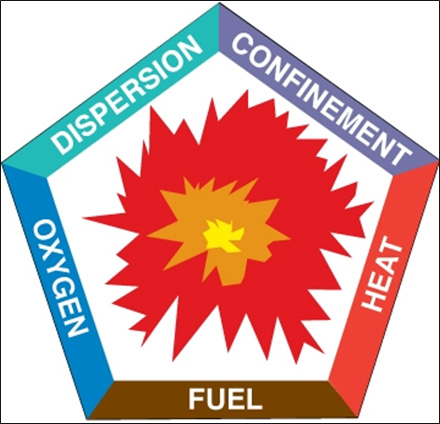

Figure III.1. Fire Triangle

When ethanol vapor combines with air in the presence of ignition sources, fires and explosions can result. The lower and upper explosive limits of ethanol are 3.3 percent and 19 percent, respectively, by volume in air. This range spans air concentrations of ethanol that can ignite and burn in the presence of an ignition source (OSHA/EPA, 2011). As the ethanol is blended or denatured (e.g., using gasoline) the explosive limits of the product mixture change slightly. As an example, a blend of 85 percent ethanol and 15 percent gasoline has lower and upper explosive limits of 1.4 percent and 19 percent, respectively (Shaw, 2011). Another key factor is that high-ethanol fuels can form flammable mixtures in the headspace of storage tanks at ordinary temperatures. Gasoline, by way of contrast is usually too rich (above its upper flammable limit) to support combustion in gasoline storage tank headspaces (ullage). Another important physical property of ethanol is that its vapors are heavier than air, this is apparent from ethanol's vapor density (approximately 1.6). Thus, ethanol vapors do not rise in air and tend to accumulate at ground level until dispersed by wind or ventilation (if inside a structure).

At ethanol manufacturing facilities, fire and explosion hazards are present from the time ethanol is first formed through product purification, storage, and transport. As shown in the fire triangle in Figure III.1, three components must be present for a fire to occur: fuel, oxygen (oxidizing agent), and heat (All About Fire, NFPA, 2011b). For ethanol fires, the ethanol vapor represents the "fuel" in the fire triangle; oxygen is the "oxidizing agent;" and, the "heat" component comes from ignition sources that cause the ethanol vapor to first burn.

Several factors can contribute to the release of ethanol, thus providing the fuel for an ethanol fire. These factors include improper storage, accidental releases (e.g., spills, containment failures), undetected leaks, inadequate venting of gases, equipment malfunctions, human error, and transportation accidents. Ethanol spills must be carefully addressed, because flammable vapors will form above all areas where the liquid ethanol travels. Examples of typical ignition sources in areas where ethanol is handled include electric arcs, human activities (e.g., smoking), heating equipment (e.g., furnaces and ovens), open flames, static electricity, and frictional heat. One of the most common ignition sources encountered at these facilities is "hot work" activities, such as welding, cutting, and grinding.

Fires fueled by pure ethanol generate no visible smoke and have a blue flame that may be difficult to see. Fires fueled by denatured ethanol produce no smoke or minimal smoke, but have a faint orange flame that may be noticeable. Fires fueled by ethanol are particularly challenging because they are not easily extinguished by traditional firefighting methods. Some commonly used fire suppression foams (e.g., those used to extinguish gasoline fires) are ineffective on ethanol fires, so special alcohol-resistant foams must be used.

Saccharification Tank Explodes

A contractor was killed and a worker suffered acid burns when an ethanol manufacturing facility's saccharification tank exploded. The 50-foot tall tank contained 40,000 gallons of corn mash. A welding contractor was cutting a hole in the top of the tank so workers could remove and load material from the top. Reportedly, atmospheric conditions had not been checked before the worker began welding, and flammable ethanol vapors had built up inside the tank. The welding ignited the vapors, and the resulting explosion threw the entire tank 75 feet. This event ruptured several interconnecting pipes, which in turn discharged an estimated 1,700 gallons of sulfuric acid. In addition, the saccharification tank landed on an empty railcar and an ethanol-containing tanker truck, causing the ethanol to catch fire. The facility's saccharification tank and fuel load-out area were destroyed during the incident, and other equipment was heavily damaged.

The following are some common areas at ethanol manufacturing facilities that present flammability hazards (Gardiner et al., 2008, 2010).

- Distillation process area. Ethanol is initially formed at manufacturing facilities prior to distillation. However, the distillation process area is typically where the liquid contains high concentrations of ethanol and becomes flammable. This part of the facility, therefore, has significant flammability hazards due to the presence of highly concentrated ethanol vapors and heat. Overpressure or mechanical damage in the distillation columns can cause ethanol vapors to leak, which presents a hazardous situation due to the various ignition sources present and the potential for workers to be exposed beyond OSHA's permissible exposure limit (PEL) for ethanol (1,000ppm for a time-weighted average, 29 CFR 1910.1000 Table Z1). This hazard also exists for other equipment (e.g., piping, molecular sieve) typically found in the distillation process area.

- Fuel storage tank area. Ethanol manufacturing facilities usually store their finished products–both ethanol and denatured ethanol– in large storage tanks before the product is distributed into commerce. Proper handling of the ethanol is critical to avoid leaks in tanks and interconnecting equipment and to prevent more catastrophic ruptures. Some important concerns include pipe ruptures, tank ruptures, and lightning strikes.

-

Storage tank headspace. The headspace is the gas-phase area above liquids inside a tank or other vessel. Recent research found the headspace vapors of denatured ethanol to be flammable at room temperature (64°F) and all temperatures down to approximately 22°F (NREL, 2008). No upper flammability limit was established for the denatured ethanol evaluated in the study and no tests were conducted at elevated temperatures. Instead, the denatured ethanol approached its lower (lean) flammability limit as the ambient temperature was lowered and eventually would not ignite if it was too cold (NREL, 2008).

Fire occurs when there is an ignitable vapor-air mixture and a source of ignition, such as a static discharge (for some examples of previous incidents refer to the United States Chemical Safety and Hazard Investigation Board (USCSB) reports for: Barton Flammable Liquid Explosion and Fire (9/18/2008) and Barton Solvents Explosions and Fire (6/26/2008)). Static electricity may be generated as liquid flows through ungrounded pipes, valves, and filters while being transferred. It can also be produced by en-trained water or air, splashing or agitation, and when sediment in the bottom of the tank becomes suspended.

At normal handling temperatures, flammable storage tanks, like those containing materials such as gasoline, may contain vapor-air mixtures that typically cannot be ignited because the vapor-air mixture is too "rich" (i.e., contains too much fuel and not enough oxygen or is above the gasoline's upper flammability limit) to burn. However, other flammable liquids, including ethanol and high ethanol content fuels, may form ignitable vapor-air mixtures inside tanks at normal handling temperatures.

-