Lead: Secondary Lead Smelter eTool

Raw Materials Processing » Handling and Transport

Handling and transportation of feed materials is an essential part of the secondary lead smelting process. Material is primarily transported through the use of mobile equipment (forklifts, front-end loaders). Proper operator training, prudent work practices, and good housekeeping are key in minimizing lead emissions during mobile equipment operation. Conversely, careless equipment operation coupled with inadequate housekeeping can lead to serious lead exposure throughout the plant.

Certain material transporting operations call for mechanical conveyance. Some common mechanical conveyance methods used in secondary lead smelters include:

Potential Sources of Exposure

-

Lead dust from feed materials can become airborne during handling and transport (Fig. 1).

-

Settled lead dust on surfaces and equipment may become airborne by vehicle traffic and wind.

-

Dust may be generated while mixing feed materials outside ventilated areas prior to charging.

Possible Engineering and Work Practice Controls

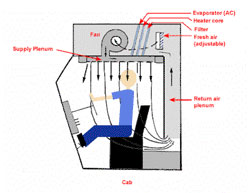

- Provide vehicles with enclosed cabs that have positive-pressure, HEPA-filtered air.

- Keep all surfaces wet and clean through the use of water supply systems and central vacuum cleaners.

-

Maintain positive-pressure, HEPA-filtered air system on mobile equipment to ensure effective operation. Check and change air filters regularly as part of an effective scheduled preventative maintenance program.

-

Remain inside the vehicle and keep doors and windows shut during mobile equipment operation in contaminated areas.

-

Reduce vehicle speeds to minimize the stirring up of settled dust.

-

Vacuum the inside of mobile equipment frequently.

-

Pave all roadways to facilitate housekeeping.

-

Wet down raw materials storage to suppress the dust generation.

-

If it is determined that lead dust is coming from mobile equipment or is coming from adjacent areas, evaluate material handling patterns and practices and area isolation.

With video exposure monitoring (VEM), worker exposures to lead are monitored and recorded with a direct reading instrument. At the same time, workplace activities are recorded on a videotape. The right hand bar indicates changes in total dust concentrations over time.

As the employee moves slag from the furnace to the slag pot cooling area with a front-end loader, the increasing red bar indicates that employee exposure may be from the stirring up of settled lead dust from the floor or possibly fugitive emissions from the furnace.

Belt conveying systems can be used to transport furnace feed material from storage to battery shredders and the furnace charging area.

Potential Source of Exposure

- Lead dust may be emitted from open conveyor systems:

- At the receiving end

- At the discharge end

- At the underside of conveyor

- From spillage along the conveyor belt

Possible Engineering and Work Practice Controls

-

Provide an enclosed conveying system, such as a screw conveyor, in place of a chain-drag or open conveyor belt where possible.

- Totally enclose and exhaust ventilate the conveyor from loading to transfer points.

-

Provide a trough belt and conveyor skirting to minimize spillage.

-

Provide a baffle to ensure the unloading of conveyor at transfer point.

-

Provide a belt scraper at the discharge end to dislodge dust particles that may adhere to the belt surface.

-

Provide access doors to conveyor and transfer point enclosures to facilitate maintenance, wash down, and other activities.

-

Use top-hinging doors for inspection to prevent spillage of leaded material.

-

Provide drains and sumps in conveyor trench to collect wash water and mud.

-

Provide hose bibs for manually washing the conveyor equipment.

-

Wet down materials to suppress dust generation.

Screw conveyors are commonly used in the secondary lead smelting industry to transport flue dust from the baghouse to an agglomeration furnace or a storage area (Fig. 2).

Potential Sources of Exposure

-

Lead dust may be emitted from leaking screw conveyors and at furnace discharge points.

Possible Engineering and Work Practice Controls

- Enclose screw conveyor systems that transport leaded materials.

-

Enclose and exhaust ventilate screw conveyor transfer points.

-

Maintain cover gaskets and repair leaks immediately.

Note: The screw conveyor can not be used for charging smelting furnaces.

Commercially available bucket elevators and drag chains may be used in conjunction with some material handling operations.

Potential Sources of Exposure

-

Leaded materials may leak from the feed or discharge end of the elevator.

Possible Engineering and Work Practice Controls

- Provide a properly-designed and exhaust-ventilated bucket elevator.

-

Minimize dust generation when feeding the bucket elevator by keeping the height of the material free-fall to a minimum and by gently loading material into the bucket elevator.

-

Enclose and exhaust ventilate the chutes between the elevator discharge and the receiving furnace.

-

Repair any holes or openings in the casings of the bucket elevator or chutes.