Poultry Processing Industry eTool

Cutting & Deboning » Deboning

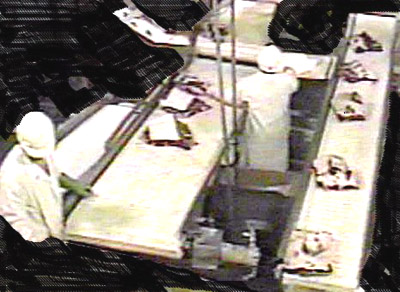

All parts of the chicken that have sufficient meat are candidates for a bone-out product. The deboning process generally follows the cutting operation when deboning legs and thighs. The breast meat, however, may be removed while the carcass is still on the cone at the end of the cutting process. In some facilities, the birds are aged in a cooler before the meat is separated from the bone. While most deboning cuts are performed with a knife, some of the processes, such as removal of the meat from the bone of the leg, can be more easily and safely accomplished by using other cutting tools such as a Whizzard knife. Trimming tasks in this process are generally performed with scissors. After the meat has been removed from the bone it may be quick frozen and bagged with little additional trimming or processing, or it may be moved to a separate specialty trim line where it is trimmed and cut according to customer requirements.

This operation includes the following tasks:

- Task 1: Skin Puller: Pulls skin from thighs and breasts.

- Task 2: Line Loader: Places parts on conveyor for deboning.

- Task 3: Deboner: Uses knife to remove bone from various sections of poultry leaving a "meat only" product.

- Task 4: Tender Puller: Pulls tenders from both sides of the deboned breast.

- Task 5: Trimmer: Removes unwanted parts with scissors or knife.

- Task 6: Quality Control Inspector: Inspects product.

- Support Tasks:

- Knife Person: Collects, sharpens, and replaces knives.

Task 1: Skin Puller

Employee uses pliers or similar tool to pull skin from breasts, thighs and legs.

Hazards of this task may include:

Hazardous Situation

Standing for a long time reduces blood flow to the legs, forces isolated muscles to work for an extended time, and increases risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can lift one foot, allowing them to continually shift their posture.

Hazardous Situation

Employees exert high finger force with both hands to open and close the tool and to hold the product while the skin is being pulled. Using gloves and handling cold product increases the amount of finger force that must be exerted. Repeatedly exerting high finger force can stretch and fray the tendon if there are not sufficient periods of rest. Repeatedly stretching the tendon can lead to tendinitis or tenosynovitis. Using standard in-line tools can cause employees to bend the wrist, which, in combination with high finger force, can cause contact trauma between the tendon and the bones and ligaments of the wrist. Contact between these entities can cause irritation and inflammation, leading potentially to tendinitis, tenosynovitis, and carpal tunnel syndrome.

Possible Solutions

- Provide appropriate hand tools.

- Use a clamp or jig to hold chicken parts while pulling skin.

- Use gloves with rough surfaces to hold chicken parts.

- Rotate to non-hand intensive tasks.

Task 2: Line Loader

Parts are transported from the cutting stations to the deboning stations in hand-carried tubs. Tubs may be lifted from cart shelves or lifted from the floor and carried to deboning stations. Tubs are emptied onto a conveyor or staging shelf which is generally at waist- to shoulder-height. This task may also be repeated at the trimming lines where product that has been de-boned may again be placed in a tub and transported to the trimmers.

Hazards of this task may include:

Hazardous Situation

Repeatedly bending forward and reaching out away from the body stresses the back even if there is a little weight being lifted because the upper body must be supported. When loads are being lifted, bending over at the waist increases the distance the load is held away from the body and increases the stress placed on the back. Bending and lifting heavy loads such as those encountered at these stations greatly increases the risk of injury to the low back.

Possible Solutions

- Place tubs on shelves that are waist high so employees do not need to bend when lifting.

- Place product in larger transport tubs, then use a tilter dumper to elevate and tilt so the contents are continually moved forward toward the employee and are maintained at about waist height at all times.

- Place product in larger transport tubs, then use a tub dumper at the workstation to empty contents on the conveyor.

- Use conveyor or auger to mechanically transport product from one station to the other.

Task 3: Deboner

Employees remove bones from various poultry parts, including breasts, thighs and legs. The task may be performed with a standard knife on a flat cutting surface or a tilted cutting surface. Legs may be deboned on a specialized conveyor line using a Whizzard knife. Breast meat may be removed directly from the carcass while it is still on the cone line.

Hazards of this task may include:

Hazardous Situation

Workers use a knife to cut the meat away from the bone. Most knives have a straight, in-line design. Using this type of knife on a horizontal cutting surface forces employees to bend their wrists to perform the cut. Bending the wrist while exerting finger force is stressful to the tendons and muscles of the hand and forearm. Factors such as poorly fitting gloves, slick handles, inappropriately sized handles, frozen meat or dull knives increase the force that must be used. Minimize finger force and bending of the wrist when performing the cutting task.

Possible Solutions

- Keep knives sharp and in good condition.

- Remove damaged knives from service.

- Use knives appropriate for the task.

- Provide properly sized gloves.

- Tilt work surfaces towards employees to reduce wrist deviation.

- Divide the task into specific units and provide an appropriate cutting tool so the task can be performed with a neutral wrist and body posture.

Hazardous Situation

Employees are performing highly repetitive tasks using knives close to other employees. Cuts and lacerations are possible to the employee and those standing nearby because employees are exposed to sharp knife blades. Any cut not treated at once will normally become infected as a result of working with poultry.

Possible Solutions

- Allow sufficient room for each employee on the line.

- Use mesh glove on non-cutting hand.

- Maintain sharp blades.

Hazardous Situation

Employees repeatedly reach to a conveyor or shelf to obtain parts for deboning and reach to place finished product in tubs or receptacles. Repetitive reaching stresses the shoulder and upper back.

Possible Solutions

- Use diverter bars to push product closer to the employee.

- Reduce width of cutting surfaces so product can be presented closer to the employee.

- Position cones and other work fixtures so all activities of the task can be performed with the elbows in close to the torso.

- Provide height-adjustable stands, where appropriate, to place employee in proper orientation to the work surface.

Hazardous Situation

Standing for a long time reduces blood flow to the legs and forces isolated muscles to work for extended periods of time. This increases the risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Task 4: Tender Puller

Tender pullers use their fingers to pull tenders away from the breast bone after the main section of breast has been removed. This task may be performed while the carcass is on the cone line or from a cut full breast placed on a flat work surface.

Hazards of this task may include:

Hazardous Situation

Employees repeatedly reach to conveyor or shelf to obtain breasts, reach to cones to pull tenders, or reach to place finished product in tubs or receptacles. Repetitive reaching stresses the shoulder and upper back.

Possible Solutions

- Use diverter bars to push product closer to the employee.

- Reduce width of work surfaces so the product is presented closer to the employee.

- Position cones and other work fixtures so all activities of the task can be performed with the elbows in close to the torso.

- Provide height-adjustable stands, where appropriate, to place employee in proper orientation to the work surface.

Hazardous Situation

Standing for a long time reduces blood flow to the legs, forces isolated muscles to work for an extended time, and increases risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Task 5: Trimmer

Trimming is usually the last processing step before packaging or quick freezing. Trim lines often produce specialty products according to customer specification. Trimmers remove pieces of bone, fat, tendons, gristle, or blemishes in the meat as well as perform specialty cutting to produce tenders and nuggets. Many of the items, such as bone and fat, that are easily grasped can be pulled away from the meat using only the fingers. Although a knife can be used, for the majority of these operations the tool of choice is usually scissors.

Hazards of this task may include:

Hazardous Situation

Use of traditional scissors forces the fingers to repeatedly open and close the jaws, which can stress tendons, increasing the risk of tenosynovitis and carpal tunnel. Contact trauma to the sides to fingers can damage nerves, which can cause numbness and tingling in the tips of the fingers and thumb.

- Provide pneumatic scissors; these scissors can be activated by employees with little finger force and with the wrist in a neutral posture. A cut proof glove should be used on non-cutting hand.

- Provide spring activated scissors; these scissors open automatically after each cutting motion.

- Rotate to those tasks that do not require scissor use.

Hazardous Situation

Standing for a long time reduces blood flow to the legs, forces isolated muscles to work for an extended time, and increases risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Hazardous Situation

Employees repeatedly reach to a conveyor or shelf to obtain parts for trimming and reach to place finished product in tubs or receptacles. Repetitive reaching stresses the shoulder and upper back.

Possible Solutions

- Use diverter bars to push the product closer to the employee.

- Reduce width of the work area so the product is presented closer to the employee.

- Position cones and other work fixtures so all activities of the task can be performed with the elbows in close to the torso.

- Provide height-adjustable stands, where appropriate, to place employee in proper orientation to the work surface.

Task 6: Quality Control Inspector

Employee pulls selected processed parts from conveyor line and visually inspects for compliance with quality standards.

Hazards of this task may include:

Hazardous Situation

Employees repeatedly reach to a conveyor or shelf to obtain parts for inspection. Reaches are also necessary to place inspected parts in tubs or back on the line. Repetitive reaching stresses the shoulder and upper back.

- Use diverter bars to push the product closer to the employee.

- Reduce width of conveyors so the product is presented closer to the employee.

- Position employee so all activities of the task can be performed with the elbows in close to the torso.

Hazardous Situation

Standing for a long time reduces blood flow to the legs, forces isolated muscles to work for an extended time, and increases risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Support Task: Knife Person

A knife person collects dull knives from employees along the processing lines and replaces them with sharp ones. This employee may also sharpen knives that have been collected.

Hazards of this task may include:

Hazardous Situation

Workers walk all over the facility on wet floors that may have bird skin, bird parts, and ice on them, creating a slipping hazard. Metal drain covers on the floor are also very slippery and pose a hazard. A falling worker may contact dangerous equipment, or cut him/herself on a knife blade.

Possible Solutions

- Cover drains with non-slip grating.

- Provide workers with non-slip footwear and require its use.

- Paint floors with slip-resistant paint or install non-slip floor tile.

- Provide guardrails at workstations adjacent to dangerous equipment to prevent injury.

- Carry knives in sheaths or closed containers.

Hazardous Situation

Employees may suffer cuts, lacerations, skin abrasion, contusions, or eye damage during use of grinders to sharpen knives. Grinding wheels may break up or explode. Bits and pieces of knife blades may be thrown off during sharpening.

Possible Solutions

- Use safety goggles or other protective eyewear.

- Use only grinding wheels with rpm rating matching the spindle speed of the grinder.

- Use ring test procedure to check for non-visible damage to the grinding wheel.

- Follow manufacturer's recommendations for guarding and use of the grinding wheel.