Poultry Processing Industry eTool

Tasks » Packout

Packaging is necessary to get the processed product from the plant to the consumer. It is generally a two-part procedure. First, the bird or bird parts are placed in a bag or package; and second, the package is placed in a shipping box. Poultry can be packaged in a wide variety of formats which range from minimal processing to maximum processing.

Packaging Options:

- Whole Bird Bulk Packaging: The whole bird can be bulk boxed and sent to large users such as broiler restaurants or secondary processors.

- Whole Bird Individual Packaging: The whole bird is individually bagged and boxed for supermarket sale.

- Bone-In Product: Parts are packaged and sold as consumer product or as bulk sale for large commercial users.

- Bone-Out Product: Parts are packaged and sold as consumer product or as bulk sale for large commercial users.

No matter how a bird is packaged it is almost always placed in a large cardboard box for shipping. The steps in building, filling, weighing, and stacking these boxes is almost always the same.

- Task 1: Box Maker: Takes/makes hand-formed boxes or machine-formed boxes and puts them on conveyor.

- Task 2: Box Packer: Packs birds into boxes for shipping.

- Task 3: Scale Operator: Pulls boxes onto scales, adds or removes extra chicken.

- Task 4: Box Sealer: Pushes air out of and seals box.

- Task 5: Stack Off: Removes boxes from the conveyor and stacks on pallet.

Task 1: Box Maker

The box maker is responsible for building boxes out of flat box stock and providing them to the stations where they will be filled with product. This task may be automated.

Hazards of this task may include:

Hazardous Situation

Problems can occur at this task because it is often an unplanned workstation, originally intended to be temporary. Placing such a workstation in a process line without adequate planning and space allocation can result in a highly congested work area, creating the potential for injury from working in awkward postures and coming in contact with other moving machinery.

Possible Solutions

- Redesign task station to provide adequate room for the worker and performance of the task.

- Whenever possible, replace manual operations with automated operations.

Hazardous Situation

Problems can occur at this task station from exposure to hot glue as boxes are made. There is potential for employee burns and splashing hot glue when adding glue sticks to the pot, or when cleaning the machine.

Possible Solutions

- Wear protective gloves

- Whenever possible, replace manual operations with automated operations.

- Provide first aid for burns to prevent infection.

Hazardous Situation

Box making operations are often placed in remote and hard-to-get-to locations, which makes access to emergency exits difficult. Quick and easy access to emergency exits from any room or workstation is very important to the safety of the employee. Without it, employees could be trapped or killed if unable to reach emergency exits during an emergency.

Possible Solutions

- Designate emergency exits and platforms/walkway with stairs to move to lower levels.

- Post emergency escape routes in all areas of the plant.

- Keep emergency exits clear.

- Educate employees on what to do in the case of an emergency evacuation.

Hazardous Situation

Employees are required to repeat the same motion over and over, (i.e., reaching and or bending to obtain box stock and placing finished boxes on conveyor), which can result in work-related musculoskeletal disorders.

Possible Solutions

- Use a palletizer to maintain the position of box materials so the employee can stand up-right and keep arms in close to the body during tasks.

- Whenever possible, replace manual operations with automated operations.

- Rotate tasks.

Task 2: Box Packer

Packing boxes involves taking packed trays, bags, or whole birds, from the conveyor and depositing them in a box. Employees generally work at a boxing station located next to a conveyor which supplies product to be boxed.

Hazards of this task may include:

Hazardous Situation

Employees repeatedly reach to conveyor to obtain product for processing and may reach to place product in the box. Repetitive reaching stresses the shoulder and upper back.

Possible Solutions

- Use diverter bars to push the product closer to the employee.

- Reduce width of conveyor so the product is presented closer to the employee.

- Position packing fixtures and product so all activities of the task can be performed with the elbows in close to the torso.

- Tilt work surface so product slides to the employee.

- Develop both left- and right-hand stations so employees can rotate through different stations and experience periods of working rest.

- Provide adjustable work tables or stands so task can be performed without torso bending or reaching.

Hazardous Situation

Standing for a long time reduces blood flow to the legs and forces isolated muscles to work for extended periods of time. This increases the risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Task 3: Scale Operator

A scale operator pulls filled boxes from a conveyor and places them onto scales. The operator then adds or removes product until the desired weight is achieved. This employee usually affixes a label showing the box weight before placing the weighed box back on the conveyor.

Hazards of this task may include:

Hazardous Situation

Employees may experience back strain from reaching, twisting, and bending if the task requires them to lift boxes, which may weigh 40-80 pounds, from the conveyor to the scales.

Possible Solutions

- Whenever possible, replace manual operations with automated operations. For example, install conveyors to transport boxes to scales.

- Reduce the amount of weight to be lifted. If containers must be lifted by employees, reduce the amount each container weighs.

- Establish a workplace ergonomic program that teaches employees to avoid using awkward postures such as twisting and bending while lifting.

- Provide mechanical lifting devices if boxes must be lifted from the conveyor to a scale.

- Incorporate scales into the conveyor so boxes do not need to be lifted.

Hazardous Situation

Standing for a long time reduces blood flow to the legs and forces isolated muscles to work for extended periods of time. This increases the risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Task 4: Box Sealer

After weighing takes place, the box sealer adds ice as required and places a lid on the box. Sealer pushes box down conveyor to stack off employee.

Hazards of this task may include:

Hazardous Situation

Standing for a long time reduces blood flow to the legs and forces isolated muscles to work for extended periods of time. This increases the risk of fatigue and varicose veins.

Possible Solutions

- Install sit/stand stools, which allow employees to lean and have their weight supported while still remaining in an upright posture.

- Rotate employees to tasks that do not require prolonged standing.

- Provide shoe insoles that cushion the feet and spread foot pressure over a larger surface.

- Provide a foot rest in front of employees so they can shift their posture.

Task 5: Stack Off

The stack off employee is responsible for removing boxes, which may weigh 40-80 pounds, from the conveyer and stacking them on pallets. Palletized loads are then stored or loaded onto trucks.

Hazards of this task may include:

Hazardous Situation

Stacking full boxes forces employees to bend the torso forward to place the box on the pallet, or to lift the box up to or above head height to place it on the top of the stack. This can result in back injuries since boxes can weigh up to 80 pounds.

Possible Solutions

- Limit the weight of boxes and arrange the workstation so loads lifted are safe according to the NIOSH Guidelines.

- Reduce the size of the box or decrease the amount of weight to be lifted.

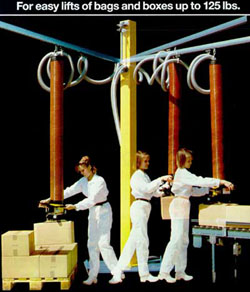

- Provide lift assists, so boxes may be lifted from the conveyor with the assist and placed on the pallet.

- Provide palletizers or scissor lifts for employees so they do not need to bend over to place boxes on pallets lying on floors.

- Develop a whole new workstation where elevated, as well as low, lifts have been eliminated.

- Rotate employees to tasks that do not require heavy lifting.

Hazardous Situation

Employees must often move pallets of product with a hand jack while stepping on wet slippery surfaces, resulting in possible slips and falls.

Possible Solutions

- Whenever possible, replace manual operations with automated operations.

- Provide a plan to keep water off walkways.

- Use non-slip floor surfaces.

- Provide employees with non-slip shoes.