Machine Guarding eTool

Introduction » General Requirements

Crushed hands and arms, severed fingers and limbs, lacerations and abrasions - the list of possible machinery-related injuries is long and horrifying. Many hazards are created by moving machine parts. Safeguards are essential for protecting workers from preventable injuries.

The following standards have been established to ensure the safety of machine operators and other employees in the area:

- Machine guarding

- Point of operation guarding

- Additional guarding

- Barrels, containers, and drums

- Exposure of blades

- Anchoring fixed machinery

- Eye and face protection

- Lockout/Tagout

For a printable sample employer self-inspection checklist for safeguards and other hazards, please see Appendix G.

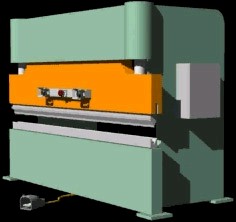

The purpose of machine guarding is to protect the machine operator and other employees in the work area from hazards created by ingoing nip points, rotating parts, flying chips and sparks. Some examples of this are barrier guards, light curtains, two-hand operating devices etc. [29 CFR 1910.212(a)(1)]

General Requirements: [29 CFR 1910.212(a)(2)]

-

Guards must not create potential hazards and must be attached to the machine where possible.

-

If guards cannot be attached to the machine, attach elsewhere.

The point of operation is the area on a machine where work is performed. [29 CFR 1910.212(a)(3)(i)]

Machines that expose an employee to injury must be guarded. The guarding device must:

-

Be in conformity with any appropriate standards. [29 CFR 1910.212(a)(3)(ii)]

-

If specific standards are not available, the machine construction should prevent the operator from having any part of his/her body in the danger zone during the operating cycle. [29 CFR 1910.212(a)(3)(ii)]

-

Special handtools used for placing and removing material from point of operation areas must allow easy handling of the material without the operator placing a hand in the danger zone. Such tools must not replace guards required by this section. [29 CFR 1910.212(a)(3)(iii)]

The following is a list of machines that usually require point of operation guarding:

[29 CFR 1910.212(a)(3)(iv)]

Revolving barrels, containers, and drums must be guarded by an enclosure interlocked with the drive mechanism, so the barrel, gun, or container cannot revolve unless the guard enclosure is in place. [29 CFR 1910.212(a)(4)]

When the periphery of the blades of a fan is less than seven (7) feet above the floor or working level, the blades must be guarded. The guard must not have openings larger than one-half (½) inch. [29 CFR 1910.212(a)(5)]

A machine designed for a fixed location must be securely anchored to prevent walking or moving. [29 CFR 1910.212(b)]

Eye and face protection must be provided to each employee when exposed to eye or face hazards from flying particles. [29 CFR 1910.133(a)]

For more information, please refer to:

- Eye and Face Protection. OSHA Safety and Health Topics Page.

The employer must establish an energy control program consisting of energy control procedures, employee training, and periodic inspections to ensure that before any employee performs any servicing or maintenance on a machine or equipment, the machine or equipment is isolated from the energy source and rendered inoperative. [29 CFR 1910.147(c)(1)]

For more information, refer to:

- Lockout/Tagout Interactive Training Program. OSHA eTool.

- Lockout/Tagout. OSHA Safety and Health Topics Page.

Click on image to view video

Click on image to view video