Machine Guarding eTool

Plastics Machinery » Thermoforming Machines

Thermoforming is a manufacturing process using thermoplastic sheet or film. Employees load the roll of plastic sheet or film on the roll-fed thermoformer roll stand and then thread it through the end feed rollers. When the machine is activated, the plastic sheet or film is advanced into the oven for heating and then into the form station where the parts are formed and then advanced to the trim station.

In general, once the equipment is up and running in the automatic mode there is little employee involvement, other than starting new rolls (roll fed thermoforming), inspecting product, packaging and removing scrap materials, unless or until something goes wrong with the equipment or process that requires employees to take corrective action. During the forming and trimming production process, employees are not exposed to the hazardous areas of the machinery unless they reach into/over these guarded areas. Once the parts are formed and trimmed, they advance to the stacker that pushes the parts upward through the plastic web. The employee visually checks the parts for defects and packs them into cartons for shipment.

The plastic web is then automatically wound on the scrap rewinder or it can be trimmed and fed into a tub, conveyor, or directly in to a grinder. If the scrap is not fed directly into a grinder, it is typically baled and then manually fed into a web grinder/granulator.

Thermoforming equipment varies in complexity, size and cost from manufacturer to manufacturer, and ranges from simple inexpensive semi automated machines to highly automated systems. There are two types of thermoforming referred to in this module:

-

In-Line Thermoforming where a sheet of plastic is fed from an extruder to an oven by use of a guide rail and pin system. (Hazards that may be associated with the extrusion process are not addressed in this module.)

-

Roll-Fed Thermoforming (Figure 1) where a sheet of plastic is fed from a roll into the oven.

The following illustrate the areas where potential hazards may be found and possible solutions may be implemented when using thermoforming machines.

The hazards that may be associated with servicing and maintenance (lockout/tagout) are not comprehensively addressed by this module.

Setup

Roll handling may be a dangerous operation if performed with the wrong tools and/or equipment. Most injuries occur while employees are loading roll stock that may weigh from hundreds to thousands of pounds. The use of overhead material handling equipment is essential to load rolls of plastic on roll-fed thermoformers (Figure 3 and 4). In addition to loading rolls of plastic, form station tools are commonly installed and removed with the use of overhead hoists and trolleys. Improper use of overhead material handling equipment may result in injury to employees.

Potential Hazards

-

Falling rolls or equipment.

-

Exceeding the lifting capacity of all material handling equipment, including slings.

-

Mechanical failures of material handling equipment.

-

Pinch points between roll or tool and thermoformer frame.

-

Struck-by material or tool moving on the trolley.

Possible Solutions

-

Properly train employees to use and maintain material handling equipment.

-

Do not exceed the capacity of material handling equipment.

-

Do not work under suspended loads.

-

Properly maintain and inspect material handling equipment. Maintenance and inspection procedures need to be established in accordance with the manufacturer's recommendations.

-

Use lifting devices to help raise rolls of plastic and tooling off the floor (Figure 5).

Highlighted OSHA Standards

-

1910.176, Handling materials

-

1910.179, Overhead and gantry cranes

-

1910.184, Slings

-

1910.212, General requirements for all machines [related topics page]

Additional Resources

OSHA Alliance Program. Hoist Manufacturers Institute (2006).

Rolls that have been loaded on the roll stand are threaded by an employee to the machine through end-feed rollers (also called the thread-up process). End-feed rollers are guarded or opened to avoid a wide range of injuries (Figure 6). There are multiple pinch points on the roll-fed feed-end unwind stand (Figure 8). Employees may be exposed to crushing, amputation, degloving, or scalping injuries that occur from hazards created by the movement of machine parts, and/or roll stock.

Potential Hazards

-

Crushing, pinching, amputation or degloving injuries may occur if hands or limbs are placed in feed mechanisms while the machine cycles (Figure 7).

-

Caught in moving machinery when loose clothing, hair or jewelry is caught by and pulled into the hazard area (i.e., guide rail and pin system or nip points).

-

Crushing, or pinching may occur if hands or fingers are caught under a rotating shaft that is not nested properly in groove (Figure 9).

Possible Solutions

-

Provide guarding solutions for the multiple pinch points (Figure 8) at the unwind stand. These may include:

-

Fixed barrier guards that require tools for removal.

-

Interlocked, moveable guards.

-

-

Use presence-sensing devices to stop machinery motion when employees enter hazardous areas.

-

Ensure rotating shaft is nested properly in its groove (Figure 9).

-

Ensure rotating shaft is properly guarded (fixed cap) or barricade area to prevent access.

Highlighted OSHA Standards

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

Production

A typical form station has the mold mounted on one platen and the pressure box mounted on the other. Vacuum holes in the mold and air pressure from the pressure box are used to produce highly defined plastic parts. The form station is often air operated. The toggle system has a flow control valve to adjust the speed at which they open or close and is used to extend and retract the forming station.

During the forming and trimming process, employees are not exposed to the hazardous areas of the machinery unless they reach into/over the guarded areas.

Potential Hazards

-

Hot surfaces that may cause burns.

-

Gases and vapors emitted from decomposing plastic.

-

Exposed electric wiring on adjacent heating oven components that may cause electric shocks.

-

Crushing, pinching, amputation or degloving injuries caused by moving machine (Figure 10).

Possible Solutions

-

Use guarding to prevent employee access to hazardous areas including:

-

Fixed barrier guards that require tools for removal (Figure 11).

-

Interlocked, moveable guards (Figure 12).

-

-

Use presence-sensing devices to stop machinery motion when employees enter hazardous areas.

-

Use locking, blocking, pinning and jacks to prevent release of stored energy.

-

Use appropriate personal protective equipment (PPE) as determined by the employer and noted in the work instructions.

Highlighted OSHA Standards

- 1910.132, Personal protective equipment, general requirements [related topics page]

- 1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

- 1910.212, General requirements for all machines [related topics page]

- 1910.219, Mechanical power-transmission apparatus

- 1910 Subpart S, Electrical [related topics page]

The trim station is often air operated and contains the cutting assembly. The cutting assembly on the trim station uses hydraulic pressure to finish the die cutting process. A toggle system is used to extend and retract the trim die. During the forming and trimming process, employees are not exposed to the hazardous areas of the machinery unless they reach into/over the guarded areas.

Potential Hazards

-

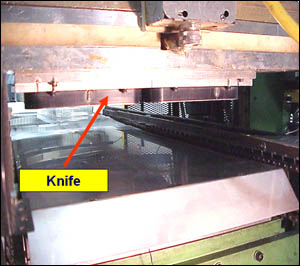

Crushing injuries or amputations may occur if hands or limbs are placed beneath the blades or between the molds or other hazardous areas while the machine cycles (Figure 13).

-

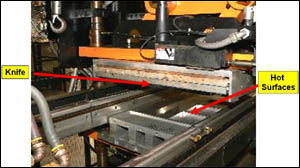

Cuts due to contact with sharp edges and blades (Figure 14).

-

Contact with live electric circuits that may cause electric shocks (Figure 14).

-

Burns caused by heated knife blade (Figure 14).

-

Contact with chains causing employee to be caught in machine.

-

Excessive noise level.

Possible Solutions

-

Follow lockout/tagout procedures during servicing, cleaning and other maintenance tasks.

-

Use proper tools and appropriate personal protective equipment (PPE) during servicing, cleaning and maintenance.

-

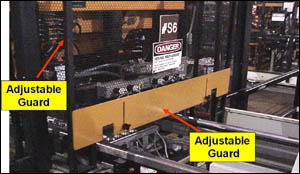

Use fixed barrier guards, interlocked gates, or adjustable barrier guards that are properly adjusted to prevent access (Figure 15 and 16).

-

Guard chains to prevent access (Figure 17).

Highlighted OSHA Standards

-

1910.95, Occupational noise exposure [related topics page]

-

1910.132, Personal protective equipment, general requirements [related topics page]

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

-

1910 Subpart S, Electrical [related topics page]

Production - Pick end process

The stacker is a bottom tool that pushes the part upward through the web into a magazine for easy counting and removal. The tooling for the stacker is usually made from wood or aluminum and the operation can be automatically performed by a robotic process. Once the parts are formed and trimmed, they advance to the stacker which pushes the parts upward through the plastic web. The employees will then visually check the parts for defects and pack them into cartons for shipment.

Potential Hazards

-

Crushing injuries and amputations may occur if hands or limbs are placed into hazardous areas (Figure 17).

-

Struck-by moving machine parts, including robots (Figure 18).

-

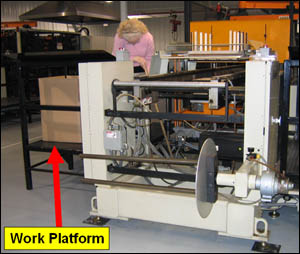

Falls from unguarded platforms.

Possible Solutions

-

Install a top fixed guard on low-profile machines to prevent reaching in from the top.

-

Position adjustable guard to prevent access to discharge parts area (Figure 19).

-

Position operator workstation to prevent access to hazardous areas of machine.

-

Guard robots and other automation to prevent entering or reaching into their space during operation (Figure 20).

-

Install guardrail on platform.

Highlighted OSHA Standards

-

1910.28, Duty to have fall protection and falling object protection.

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

Parts are visually checked for defects, counted, and packed into corrugated cartons. Due to machine configuration, platforms and/or steps are used to allow access to work areas. Work platforms may not be provided by the machinery manufacturer; however they may be fabricated by the end user. It is important to provide an even work surface at an appropriate work height for the employee in order to prevent injury.

Potential Hazards

-

Falls from unguarded platforms.

-

Slips caused by slippery surfaces.

-

Trips due to contact with steps, packing material or auxiliary equipment.

-

Lacerations due to contact with sharp objects.

-

Injury to back and shoulders due to awkward body positions.

Possible Solutions

-

Use non-slip working surfaces and/or footwear.

-

Install guardrails whenever possible, at platform heights 4 feet or more above the adjacent floor or when adjacent to dangerous equipment.

-

Provide guardrails.

-

Secure steps and/or platforms to prevent movement.

-

Use uniform step size (slope).

-

Use stable chairs.

-

Encourage employee job rotation between pick end stations.

-

Provide steps and platforms with appropriate workstation height (Figures 21, 22, and 23).

-

Use appropriate personal protective equipment (PPE), such as gloves.

Highlighted OSHA Standards

-

1910.22, Walking/working surfaces, general requirements

-

1910.28, Duty to have fall protection and falling object protection.

-

1910.132, Personal protective equipment, general requirements [related topics page]

The remaining skeletal trim scrap (Figure 24) is often rewound and collected for baling or grinding material off-line. The employee manually feeds the scrap into the rewinder (Figure 27 and 28), and removes the bale of material when the rewinder is full.

Potential Hazards

-

Pinch points caused by moving parts (Figure 25).

-

Awkward postures due to bending or reaching while pulling to remove roll.

-

Lacerations due to contact with sharp material or nips in plastic edges from pin chain.

Possible Solutions

-

Reposition the plastic scrap rewinder.

-

Use appropriate personal protective equipment (PPE), such as gloves and sleeves to prevent cuts from material nips when removing full rolls (Figure 26).

-

Use retractable knife or scissors to cut plastic webbing prior to removal.

Highlighted OSHA Standards

-

1910.132, Personal protective equipment, general requirements [related topics page]

-

1910.138, Hand Protection

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

A Guillotine Cutter (Figure 29) is often utilized to cut the skeletal trim scrap into sheets for easy collection and recycling, especially when the material is too thick to rewind. During the trimming process, employees are not exposed to the hazardous areas of the machinery unless they reach into/over these guarded areas.

Potential Hazards

-

Nip points caused by moving machinery.

-

Crushing injuries, lacerations or amputations may occur if hands or limbs are placed beneath the knife blade.

-

Dust exposure from plastic dust created during the trimming process.

Possible Solutions

-

Install safeguarding such as barriers, light curtains and safety mats on all hazardous moving machine parts (Figure 30).

-

Provide guarding to prevent access to point of operation.

-

Use ventilation system to remove dust from work area.

Highlighted OSHA Standards

-

1910.132, Personal protective equipment, general requirements [related topics page]

-

1910.134(a), Respiratory protection, permissible practice [related topics page]

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

Web grinders (granulators) (Figure 31) are a common way to dispose of web trim. Plastic scrap from the scrap rewinder is typically baled and then manually fed into a web grinder/granulator, where razor-sharp knives cut the plastic into small pieces to be recycled later. When grinding scrap roll stock, the grinder tends to pull the webbing into the grinder at a high rate.

Potential Hazard

-

Crushing injuries, lacerations and amputations due to direct access to the cutting knives, both rotary and stationery. Contact may occur if employees reach into the granulator.

Possible Solutions

-

Use energy control procedures to clean and inspect knives during changeovers of material type or material color.

-

Train employees to properly feed scrap roll stock into the grinder.

-

Manually turn rotor or flywheel to reposition machine parts that need cleaning. Apply energy control procedures before an employee performs any cleaning in order to prevent injuries, such as cuts and amputations.

-

Install safeguarding such as barriers, light curtains and safety mats on machinery to protect employees from all hazardous moving machine parts.

-

Provide anti-kickback flaps in feed throat.

-

Provide proximity guarding to prevent access from feed chute to rotating knives (Figure 32).

Highlighted OSHA Standards

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

The chain rails contain a horizontally advancing, spiked chain and sprocket system. The chain spikes pierce the plastic sheet being fed into the machine. The chain draws the sheet through the oven, form station and trim station. Properly guarded chain rails prevent employee access to moving machinery.

Potential Hazard

-

Caught in unguarded, moving chains and sprockets, which may result in punctures, lacerations, or amputations.

Possible Solutions

-

Guard chain to prevent access (Figure 33).

-

Utilize lockout/tagout procedures.

-

Avoid loose clothing and jewelry; confine long hair.

Highlighted OSHA Standards

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

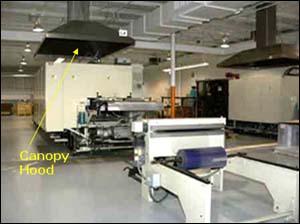

There are five types of heaters commonly used on thermoforming machines: rod, ceramic, infrared, quartz and gas catalytic. They are setup in zones within the oven (Figure 34) for the gradual heating of materials. If the material is heated too fast, it will sag on the lower heaters and cause a burnout. During the forming process, employees are not exposed to the hazardous area of the machinery unless they reach into/over the guarded areas.

Potential Hazards

-

Burns caused by hot surfaces.

-

Gases and vapors emitted from plastic decomposition may be irritating to eyes and respiratory tract if employees are exposed.

-

Exposed electric wiring on heating elements that may cause electric shocks.

-

Crushing and pinch points caused by moving machine parts (Figure 35).

Possible Solutions

-

Follow lockout/tagout procedures during servicing, cleaning and other maintenance activities.

-

Provide adequate ventilation (Figure 36). Ventilation hoods are used to remove potentially irritating gases, vapors and smoke should a burnout take place.

-

Use proper tools to conduct servicing, cleaning and other maintenance tasks.

-

Use appropriate personal protective equipment (PPE) as determined by the employer and noted in the work instructions.

-

Use access doors and other guards to eliminate exposure to hazardous areas.

Highlighted OSHA Standards

-

1910.132, Personal protective equipment, general requirements [related topics page]

-

1910.134(a), Respiratory protection, permissible practice [related topics page]

-

1910.147, The control of hazardous energy (lockout/tagout) [related topics page]

-

1910.212, General requirements for all machines [related topics page]

-

1910.219, Mechanical power-transmission apparatus

-

1910 Subpart S, Electrical [related topics page]