Machine Guarding eTool

Introduction » Hazardous Motions/Actions

A wide variety of mechanical motions and actions may present hazards to the worker. These can include the movement of rotating members, reciprocating arms, moving belts, meshing gears, cutting teeth, and any parts that impact or shear. These different types of hazardous mechanical motions and actions are basic in varying combinations to nearly all machines, and recognizing them is the first step toward protecting workers from the danger they present. The basic types of hazardous mechanical motions and actions are:

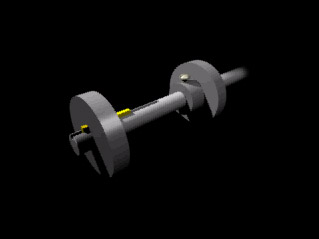

Rotating motion can be dangerous; even smooth, slowly rotating shafts can grip hair and clothing, and through minor contact force the hand and arm into a dangerous position. Injuries due to contact with rotating parts can be severe. Collars, couplings, cams, clutches, flywheels, shaft ends, spindles, meshing gears, and horizontal or vertical shafting are some examples of common rotating mechanisms which may be hazardous. The danger increases when projections such as set screws, bolts, nicks, abrasions, and projecting keys or set screws are exposed on rotating parts.

Examples of Hazardous Projections on Rotating Parts

In-running nip point hazards are caused by the rotating parts on machinery. There are three main types of in-running nips. Parts can rotate in opposite directions while their axes are parallel to each other. These parts may be in contact (producing a nip point) or in close proximity. In the latter case, stock fed between two rolls produces a nip point. As seen here, this danger is common on machines with intermeshing gears, rolling mills, and calenders.

Common nip points on rotating parts

Nip points are also created between rotating and tangentially moving parts. Some examples would be: the point of contact between a power transmission belt and its pulley, a chain and a sprocket, and a rack and pinion.

Nip points between rotating elements and parts with longitudinal motions

Nip points can occur between rotating and fixed parts which create a shearing, crushing, or abrading action. Examples are: spoked handwheels or flywheels, screw conveyors, or the periphery of an abrasive wheel and an incorrectly adjusted work rest and tongue.

Nip points between rotating machine components

Cutting action may involve rotating, reciprocating, or transverse motion. The danger of cutting action exists at the point of operation where finger, arm and body injuries can occur and where flying chips or scrap material can strike the head, particularly in the area of the eyes or face. Such hazards are present at the point of operation in cutting wood, metal, and other materials. Examples of mechanisms involving cutting hazards include bandsaws, circular saws, boring and drilling machines, turning machines (lathes), or milling machines.

Punching action results when power is applied to a slide (ram) for the purpose of blanking, drawing, or stamping metal or other materials. The danger of this type of action occurs at the point of operation where stock is inserted, held, and withdrawn by hand. Typical machines used for punching operations are power presses and iron workers.

Shearing action involves applying power to a slide or knife in order to trim or shear metal or other materials. A hazard occurs at the point of operation where stock is actually inserted, held, and withdrawn. Examples of machines used for shearing operations are mechanically, hydraulically, or pneumatically powered shears.