Machine Guarding eTool

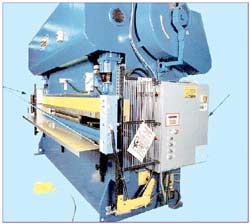

Presses » Powered Press Brakes

There are four basic types of press brakes:

- Part Revolution Mechanical Press

- Hydraulic Press

- Hydra-Mechanical Press

- Mechanical-Friction Clutch Press

These metalworking machines form parts through the use of dies attached to a plate type ram or slide and a plate-type bed. They are mechanically or hydraulically powered and are primarily used for bending and forming sheet metal. Metalworking occurs by placing stock on a bottom die and striking it with a top die attached to the movable ram.

Operator Involvement

The operator will select and install the dies, place and position the stock between the dies, activate the press cycle with palm buttons or a foot switch, and remove the completed part. These machines are normally used for prototype and semi-production processes where maximum operator involvement is required, creating many operational hazards.

Potential Hazards

-

Although most press brake operations do not require the operators to place their hands or any part of their body into the point of operation, exposure to point of operation injuries still exists. Sometimes as the piecepart bends up, a hazard may be created between the part and the front face of the slide.

-

Operating controls, especially foot pedals, introduce the possibility of accidental cycling.

-

In forming large pieces, the operator must hold the stock and cycle the press with a foot pedal. As the work stroke begins, the stock will move up or down, creating a hazard.

Solutions

- Press brake safeguarding can be accomplished by using one of the following:

Potential Hazards

-

Power transmission components should be totally enclosed.

-

The work area should be neat with non-slip floor preparation.