Machine Guarding eTool

Presses » Mechanical-Friction Clutch

This is one of the most common press brakes for metal fabrication. These clutches use a part revolution mechanical-friction clutch, usually operated by a mechanical foot pedal or treadle.

Mechanical-friction clutches are widely used because they give the operator control of the machine stroke by inching and slipping the clutch. This allows the operator to drop the slide to the workpiece and stop, adjust, or align the workpiece, then complete the stroke to bend the part.

This press also allows the operator to slip the clutch or inch through the bottom of the stroke to avoid a quick whip-up action of the material.

Operator Involvement

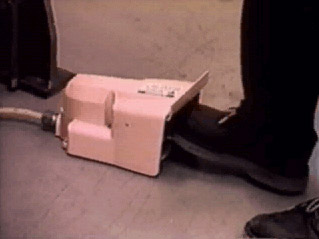

The operator is responsible for handling the stock and operating the machine stroke through use of a foot pedal. When a foot pedal is used to begin the sequence, other safety devices must be used to keep the operator's hands out of the danger zone.

Potential Hazards

-

A hand or other body part near the point of operation during cycling can result in injury.

-

Material can be sharp, slippery, or difficult to grasp.

Solutions

-

General machine guards (barrier guards, two-hand tripping devices, electronic safety devices, etc.) must be provided to protect the operator and other employees in the machine area from hazards created by point of operation, nip points, etc. [29 CFR 1910.212(a)(1)]

-

Guards must not create hazards themselves, and must be attached to the machine where possible. [29 CFR 1910.212(a)(2), (a)(3)(i)]

-

Use special hand tools to keep hands away from point of operation. [29 CFR 1910.212(a)(3)(iii)]

Potential Hazards

-

Operating controls should be located away from the die area and employ dual palm buttons.

-

If a foot pedal control is used, it must be guarded.

-

An emergency stop button should be available with easy access to the operator and a main power disconnect switch is needed.

-

Power transmission components are normally located away from the operator; however, hydraulic pump/motor arrangements should be enclosed. [29 CFR 1910.219]

-

Work area should be kept clean to prevent slipping or falling hazards.