Machine Guarding eTool

Saws » Table Saws

Table saws are used for straight sawing. Depending on the blade, they cut either across (crosscut) or with (ripsaw) the grain of the wood.

Operator Involvement

With hand-fed saws, the operator adjusts the height and angle of the blade. Then, holding the stock, the operator pushes it into the blade. A guide is used to maintain a straight cut at the desired width. At the end of the cutting stroke, the operator either changes positions or pushes the stock past the blade. Self-feed or power table saws are equipped with rollers or a conveyor system to hold the lumber and force-feed it into the saw blade.

Potential Hazard

-

Injuries can occur if an operator’s hands slip while feeding the stock into the saw, or if the operator holds his or her hands too close to the blades while cutting. The operator can also be injured when removing scrap or finished pieces of stock from the table.

Solutions

-

Enclose the portion of the ripsaw and crosscut saw above the table with a self-adjusting guard as shown. The guard must adjust to the thickness of the material being cut and remain in contact with it [29 CFR 1910.213 (c)(1) and (d)(1)]. Hinge the guard so that the blades can be changed easily.

-

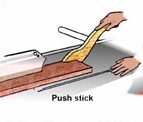

Use a push stick for small pieces of wood and for pushing stock past the blade. [29 CFR 1910.213(s)(9)]

Additional Safety Measures

-

Keep hands out of the line of the cut.

-

Attach a brake to the motor's arbor to stop the saw from coasting after the power has been cut off, or have the operator remain at the saw station after the motor is shut off, until the blade stops turning.

Potential Hazard

-

Injuries can occur if the operator makes contact with the blade under the table or with the power transmission apparatus (if not enclosed).

Solution

-

Always guard the portion of the blade below the table. Protect operators from possible contact when reaching under the table. [29 CFR 1910.213(a)(12)]

-

Always guard the power transmission apparatus (belts, pulleys, chains, sprockets, etc.). [29 CFR 1910.213(a)(9)]

Potential Hazard

-

Kickbacks occur when the blade catches the stock and throws it back toward the operator. Kickbacks can result if the blade height is not correct or if the blade is not maintained properly. Kickbacks are more likely to occur when ripping, rather than crosscutting. Kickbacks also can occur if safeguards are not used or if poor-quality lumber is cut.

-

For ripsaws, use a spreader to prevent material from squeezing the saw or kicking back during ripping. [29 CFR 1910.213(c)(2)]

-

Use anti-kickback fingers to hold the stock down in the event that the saw kicks back the material. [29 CFR 1910.213(c)(3)]

-

Maintain and sharpen blade. [29 CFR 1910.213(s)(2)]

Additional Safety Measures

-

Use the proper blade for the cutting action. For example, do not use a crosscut blade for ripping.

-

Operate the saw at the speed specified by the manufacturer.

-

Leave sufficient clearance for stock.

-

Stand to the side of the saw blade to avoid injury due to kickback.

-

Guide the wood to be cut parallel to the rip fence to minimize the potential for kickback.

-

Avoid crosscutting long boards on table saws. Considerable hand pressure is required close to the saw blade, and the boards create a safety hazard to other people.

-

Use a filler piece between the fence and the saw blade when necessary such as when there is little clearance on the fence side.

-

Properly support all pieces of stock, including the cut and uncut ends, scrap, and finished product.

Potential Hazard

-

The cutting action of the blade may throw wood chips, splinters, and broken saw teeth.

Solution

-

Remove cracked saw blades from service. [29 CFR 1910.213(s)(7)]

Additional Safety Measures

-

Maintain sharp blades.

-

Always wear eye and face protection.