Machine Guarding eTool

Introduction » Additional Safety Considerations

Safeguards must meet these minimum general requirements:

-

Prevent contact: The safeguard must prevent hands, arms, and any other part of a worker's body from making contact with dangerous moving parts. A good safeguarding system eliminates the possibility of of the operator or another worker placing parts of their bodies near hazardous moving parts.

-

Secure: Workers should not be able to easily remove or tamper with the safeguard, because a safeguard that can easily be made ineffective is no safeguard at all. Guards and safety devices should be made of durable material that will withstand the conditions of normal use. They must firmly be secured to the machine.

-

Protect from falling objects: The safeguard should ensure that no objects can fall into moving parts. A small tool which is dropped into a cycling machine could easily become a projectile that could strike and injure someone.

-

Create no new hazards: A safeguard defeats its own purpose if it creates a hazard of its own such as a shear point, a jagged edge, or an unfinished surface which can cause a laceration. The edges of guards. for instance, should be rolled or bolted in such a way that they eliminate sharp edges.

-

Create no interference: Any safeguard which impedes a worker from performing the job quickly and comfortably might soon be overridden or disregarded. Proper safeguarding can actually enhance efficiency as it can relieve the worker's apprehensions about injury.

-

Allow safe lubrication: If possible, one should be able to lubricate the machine without removing the safeguards. Locating oil reservoirs outside the guard, with a line leading to the lubrication point, will reduce the need for the operator or maintenance worker to enter the hazardous area.

Even the most elaborate safeguarding system cannot offer effective protection unless the worker knows how to use it and why. Specific and detailed training is therefore a crucial part of any effort to provide safeguarding against machine-related hazards. Thorough operator training should involve instruction or hands-on training in the following:

- a description and identification of the hazards associated with particular machines;

- the safeguards themselves, how they provide protection, and the hazards for which they are intended;

- how to use the safeguards and why;

- how and under what circumstances safeguards can be removed, and by whom (in most cases, repair or maintenance personnel only); and

- when a lockout/tagout program is required.

- what to do (e.g., contact the supervisor) if a safeguard is damaged, missing, or unable to provide adequate protection.

This kind of safety training is necessary for new operators and maintenance or setup personnel, when any new or altered safeguards are put in service, or when workers are assigned to a new machine or operation.

While these aids do not give complete protection from machine hazards, they may provide the operator with an extra margin of safety. Sound judgment is needed in their application and usage. Examples of possible application include the following:

-

An awareness barrier serves as a reminder to a person that he or she is approaching the danger area. Although the barrier does not physically prevent a person from entering the danger area, it calls attention to it. For an employee to enter the danger area, an overt act must take place, that is, the employee must either reach or step over, under or through the barrier. Generally, awareness barriers are not considered adequate when continual exposure to the hazard exists.

-

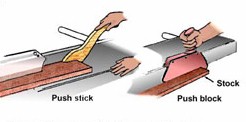

Special hand tools may be used to place or remove stock, particularly from or into the point of operation of a machine. A typical use would be for reaching into the danger area of a press or press brake. A push stick or block may be used when feeding stock into a saw blade. When it becomes necessary for hands to be in close proximity to the blade, the push stick or block may provide a few inches of safety and prevent a severe injury.

Today many builders of single-purpose machines provide point-of-operation and power transmission safeguards as standard equipment. However, not all machines in use have built-in safeguards provided by the manufacturer.

Guards designed and installed by the builder offer two main advantages:

- They usually conform to the design and function of the machine.

- They can be designed to strengthen the machine in some way or to serve some additional functional purposes.

User-built guards are sometimes necessary for a variety of reasons. They have these advantages:

- Often, with older machinery, they are the only practical safeguarding solution.

- They may be the only choice for mechanical power transmission apparatus in older plants, where machinery is not powered by individual motor drives.

- They permit options for point-of-operation safeguards when skilled personnel design and make them.

- They can be designed and built to fit unique and even changing situations.

- They can be installed on individual dies and feeding mechanisms.

- Design and installation of machine safeguards by plant personnel can help to promote safety consciousness in the workplace.

User-built guard disadvantages:

-

User-built guards may not conform well to the configuration and function of the machine.

-

There is a risk that user-built guards may be poorly designed or built.

Many feeding and ejection methods do not require the operator to place his or her hands in the danger area. In some cases, no operator involvement is necessary after the machine is set up. In other situations, operators can manually feed the stock with the assistance of a feeding mechanism. Properly designed ejection methods do not require any operator involvement after the machine starts to function.

Using these feeding and ejection methods does not eliminate the need for guards and devices. Guards and devices must be used wherever they are necessary and possible in order to provide protection from exposure to hazards.

Types of feeding and ejection methods:

- Automatic Feed

- stock is fed from rolls, indexed by machine mechanism, etc.

- eliminates the need for operator involvement in the danger area

- other guards are required for operator protection, usually fixed barrier guards

- requires frequent maintenance

- may not be adaptable to stock variation

- Semiautomatic Feed

- stock is fed by chutes, movable dies, dial feed, plungers, or sliding bolster

- Automatic Ejection

- work pieces are ejected by air or mechanical means

- may create a hazard of blowing chips or debris

- size of stock limits the use of this method

- air ejection may present a noise hazard

- Semiautomatic Ejection

- work pieces are ejected by mechanical means which are initiated by the operator

- operator does not have to enter danger area to remove finished work

- other guards are required for operator protection

- may not be adaptable to stock variation

- Robots

- they perform work usually done by operator

- operator does not have to enter danger area

- are suitable for operations where high stress factors are present, such as heat and noise

- can create hazards themselves

- require maximum maintenance

- are suitable only to specific operations

Good maintenance and repair procedures contribute significantly to the safety of the maintenance crew as well as that of machine operators. The variety and complexity of machines to be serviced, the hazards associated with their power sources, the special dangers that may be present during machine breakdown, and the severe time constraints often placed on maintenance personnel all make safe maintenance and repair work difficult.

If possible, machine design should permit routine lubrication and adjustment without removal of safeguards. But when safeguards must be removed, and the machine serviced, the lockout procedure of 29 CFR 1910.147 must be adhered to. The maintenance and repair crew must never fail to replace the guards before the job is considered finished and the machine released from lockout.

In order to prevent hazards while servicing machines, each machine or piece of equipment should be safeguarded during the conduct of servicing or maintenance by:

- notifying all affected employees (usually machine or equipment operators or users) that the machine or equipment must be shut down to perform some maintenance or servicing;

- stopping the machine;

- isolating the machine or piece of equipment from its energy source;

- locking out or tagging out the energy source;

- relieving any stored or residual energy; and

- verifying that the machine or equipment is isolated from the energy source.

Although this is the general rule, there are exceptions when the servicing or maintenance is not hazardous for an employee, when the servicing which is conducted is minor in nature, done as an integral part of production, and the employer utilizes alternative safeguards which provide effective protection as is required by 29 CFR 1910.212 or other specific standards. When the servicing or maintenance is completed, there are specific steps which must be taken to return the machine or piece of equipment to service. These steps include:

- inspection of the machine or equipment to ensure that all guards and other safety devices are in place and functional,

- checking the area to ensure that energization and start up of the machine or equipment will not endanger employees,

- removal of the lockout devices,

- reenergization of the machine or equipment, and

- notification of affected employees that the machine or equipment may be returned to service.

If it is necessary to oil machine parts while the machine is running, special safeguarding equipment may be needed solely to protect the oiler from exposure to hazardous moving parts. Maintenance personnel must know which machines can be serviced while running and which can not. The danger of accident or injury is greatly reduced by shutting off and locking out all sources of energy.