Machine Guarding eTool

Presses » Pullbacks/Pullouts

Pullbacks/pullouts are used as safeguarding devices on both full and part revolution power presses. They are similar to restraints, but pullbacks are designed to pull the operator's hands away from the area of the closing dies (point of operation) during each stroke of the power press.

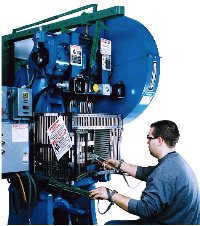

Wrist bands, are secured around both wrists of the operator, and the pullback is adjusted for the particular operator and the particular die installed within the press. When the press stroke begins the pullback device pulls the wrist bands away from the die located within the press. An overhead pullback device (above) is commonly used in press brakes that perform long-run jobs and when small to medium-size parts are being produced. It allows the operator freedom of movement for loading and unloading parts without interference.

- Attachments must be connected to and operated only by the press slide or upper die. [29 CFR 1910.217(c)(3)(iv)(a)]

- Attachments must be adjusted to prevent the operator from reaching into the point of operation or to withdraw the operator's hand from the point of operation before the dies close. [29 CFR 1910.217(c)(3)(iv)(b)]

- A separate pullout device must be provided for each operator if more than one operator is used on the press. [29 CFR 1910.217(c)(3)(iv)(c)]

- Each pull-out device in use must be inspected and checked for proper adjustment at the start of each operator shift, following a new die set-up, and when operators are changed. Necessary maintenance or repair on both must be performed and completed before the press is operated. [29 CFR 1910.217(c)(3)(iv)(d)]

- Inspection and Maintenance Records. It is the responsibility of the employer to make periodic and regular safety inspections and keep accurate records of them. [29 CFR 1910.217(e)(1)(i)]

When using pullbacks, visually inspect and check for proper adjustment of the pullbacks each time operators change, following a new die setup, and at the start of each shift

Make sure die protrusions do not interfere with the pulling action. Continuing supervision and instruction is required.