Machine Guarding eTool

Horizontal Injection Molding Machines » Safety Tour - View 1

Intro | View 1 | View 2 | View 3

Featured Areas

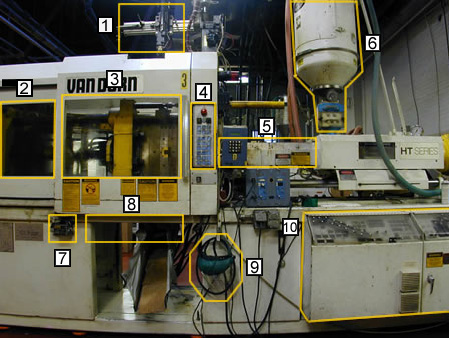

A robot can be attached to, or placed adjacent to, an injection molding machine to automate repetitive or potentially hazardous tasks. The robot in the image to the left is placed on top of the injection molding machine for vertical entry. The robot must be guarded to prevent workers from entering or reaching into its space during operation. [Photo description: Highlighted area includes a silver robot above the injection molding machine.] View close-up

This movable guard prevents access to the clamping and ejector mechanisms as well as other moving parts of the machine and mold. Do not start a machine or leave a machine operating unless this guard is in place. This guard may be fixed on some machine designs, requiring a tool to remove it. [Photo description: Highlighted area includes a movable guard.] View close-up

The operator’s gate allows the operator access to the mold and should be equipped with interlocks (such as electrical, hydraulic and/or pneumatic) that allow the machine to operate only when the gate is closed. In addition, a mechanical safety device (with a monitoring device) is provided to physically prevent the platen from closing. Do not attempt to override any of the interlocks or to reach over, under, around, or through the operator’s gate (or other guards) while the machine is operating. [Photo description: Highlighted area includes the operator's gate.] View close-up

The control panel on the front of the injection molding machine features a red Emergency Stop Button that prevents all machine motion when pressed. [Photo description: Highlighted area includes the control panel on the injection molding machine.] View close-up

The purge guard covers the nozzle of the injection molding machine and helps prevent crushing injuries or burns from the splatter of molten plastic material. The purge guard should be interlocked. [Photo description: Highlighted area includes the purge guard that covers the nozzle.] View close-up

When the hopper is in place, it guards the feed throat opening (which connects the hopper to the injection unit) and prevents insertion of a hand or limb into the area where the screw is turning. Wear appropriate personal protective equipment (PPE) and, where possible, use shields to protect employees from splatter. Safety signs should be posted to alert workers of potential hazards. If servicing and maintenance is needed, follow appropriate lockout/tagout procedures. [Photo description: Highlighted area includes the hopper guard.] View close-up

The hydraulic safety interlock valve prevents the clamp from closing when the operator’s gate is open. [Photo description: Highlighted area includes the safety interlock valve.] View close-up

Place a guard at the opening for parts discharge to prevent an employee from reaching under the operator’s gate and into the mold area. A chute, conveyor, or other object can take the place of a guard attached to the machine if it prevents access to this area. [Photo description: Highlighted area includes a guard at the opening for parts discharge.] View close-up

Personal protective equipment (PPE), such as a face shield, heat-resistant gloves, and other appropriate equipment must be worn, when necessary, while performing maintenance or servicing activities when a hazard may be present. [Photo description: Highlighted area includes personal protective equipment such as a face shield.] View close-up

The electrical cabinet guards the machine’s electrical system and protects unauthorized people from electrical hazards. [Photo description: Highlighted area includes the electrical cabinet.] View close-up