Machine Guarding eTool

Thermoforming Machine » Safety Tour - Slide 17

Featured areas in the image are numbered and described in the "Featured Areas" section located below the image.

Featured Areas

This is the form station. A typical form station has the mold mounted on one platen and the pressure box mounted on the other. Vacuum holes in the mold and air pressure from the pressure box are used to produce highly defined plastic parts. [Photo description: The highlighted area includes silver, black, and orange moving metal parts of the machine.] View close-up

The trim station is the cutting assembly and is often air operated and contains the cutting assembly. The cutting assembly on the trim station uses hydraulic pressure to finish the die cutting process. A toggle system is used to extend and retract the trim die. [Photo description: The highlighted area includes silver, black, and orange moving metal parts of the machine.] View close-up

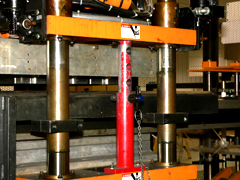

The mechanical safety device is an energy isolating device because it physically prevents movement of the platen during setup and/or adjustment. All blocking and pinning devices are used in accordance with established energy control (lockout/tagout) procedures. An important point to consider in the design of mechanical safety devices is that they must be able to withstand the forces exerted by the hazard without presenting a hazard themselves. [Photo description: The highlighted area includes a red metal brace wedged in between two moving parts preventing them from coming together.] View close-up