Oil and Gas Well Drilling and Servicing eTool

Oil and Gas Well Drilling and Servicing » Site Preparation

Site preparation activities at oil and gas well drilling sites are subject to OSHA’s Safety and Health Regulations for Construction (29 CFR 1926).

Note: Twenty-eight states and territories operate their own occupational safety and health State Plans approved by OSHA and may have different or additional requirements.

Site preparation for an oil and gas well can include:

- Transporting equipment to and from the site (see the Transportation Module of this eTool)

- Lease road construction

- Grubbing and clearing (removal of unwanted vegetation, trees, and general debris)

- Leveling the site

- Pad construction

- Digging pits and trenches

Hazards may be related to the following:

Leveling, excavating, digging, and trenching

A road to the site is first constructed and the site leveled (if necessary), typically with bulldozers and/or graders. The scale and duration of leveling, digging, excavating, and trenching are site-specific depending on the available area and terrain. On some drilling sites, a below-ground-level cellar may be excavated. This is where the main borehole is to be drilled. A reserve pit and settling pits may also be excavated and are used for water, drilling fluid (mud) storage, or discharge.

Potential Hazard

- Struck by and crushing hazards to pedestrian traffic and ground personnel.

Possible Solutions

- Perform a Job Safety Analysis (JSA) before beginning work and whenever work activities change.

- Ensure the use of high-visibility clothing and spotters when appropriate.

- Instruct spotters and pedestrians to not walk backwards, or close to operating/moving equipment, and to watch for oncoming equipment/traffic.

Potential Hazard

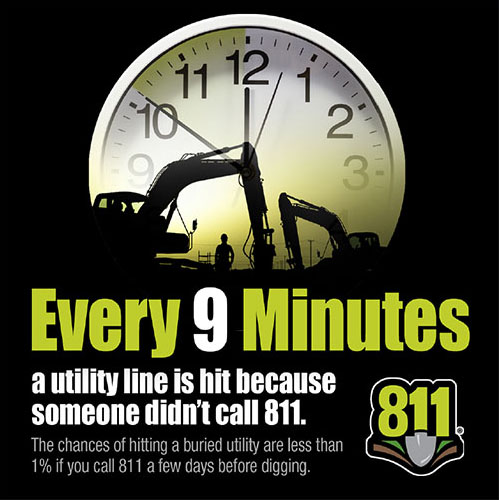

- Equipment damaging buried pipelines and cables, which could contain electrical, flammable, or toxic materials.

Possible Solutions

- Prevent damage to underground pipelines and utilities by contacting One Call prior to excavation and digging operations. Call 811 or visit 811 - Choose Your State to be routed to the One Call center in your state.

- Hand dig where utilities may be present.

Potential Hazards

- Sloping and uneven ground causing bulldozers and other mobile equipment to roll over.

- Ruts and uneven terrain. Mobile equipment can also become stuck and require recovery, creating additional challenges and hazards.

(Source: Common Ground Alliance)

Possible Solutions

- Limit pedestrian traffic during road leveling work.

- Train and require mobile equipment operators to follow equipment manufacturer requirements, including how to operate equipment on sloped and/or uneven ground.

- Eliminate ruts, slopes, and uneven walking surfaces where possible.

- Provide rollover guards on equipment used in site preparation operations. [29 CFR 1926.602]

- Provide overhead and rear canopy guards on rider-operated equipment. [29 CFR 1926.604(a)(2)]

Potential Hazards

- Inclement weather creating wet, slippery surfaces as a result of ice, snow, or rain.

- Hot or cold weather resulting in heat or cold stress related injuries.

Possible Solutions

- Plan for hazards that are the result of weather changes and weather emergencies. Obtain updates from the National Weather Service and plan site activities accordingly.

- Use water, rest, and shade during hot weather events and acclimatize employees to the heat. See OSHA's Heat Illness Prevention Campaign.

- Wear layered clothing during winter months and take frequent breaks in a heated area.

- Train employees to understand and recognize the signs and symptoms of heat and cold stress, and periodically monitor employees for these signs and symptoms.

- After weather changes, conduct inspections for new hazards.

Potential Hazards:

- Animals such as snakes, rodents, and insects, as well as irritant and toxic plants (by contact or inhalation).

- Exposure to airborne dust, pollens, and other suspended materials.

- Trench cave-in and engulfment.

- Tree trimming and clearing hazards such as falling limbs or trees, struck by mobile equipment, and other stuck-by and caught-between hazards.

Possible Solutions

- Protect employees engaged in site clearing from animal and insect hazards and from toxic or irritating plants that may be present.

- Ensure adequate information is provided to employees about abatement requirements such as long sleeves and pants, high length boots, insect repellant, initial clearing before employees enter, etc.

- Teach the employees about available first aid treatments. [29 CFR 1926.604(a)(1)]

- Utilize water trucks to keep dusts, pollens, and other particulates from becoming airborne.

- Implement and utilize appropriate personal protective equipment (PPE) for the hazards, including respiratory protection to employees who are or may be exposed to airborne dusts, pollens, or other particulates.

- Ensure employees in excavation/trenches are protected from cave-ins. [29 CFR 1926 Subpart P – Excavations]

Incident Examples

When reviewing these incidents, consider which of the Possible Solutions listed above could have prevented the incidents.

- A crew of two workers was surveying a corner plot of land, which was adjacent to a roadway, for oil and gas operations. One of the workers stepped into the roadway to place a surveying rod upon a monument that was on the centerline of the road. The worker was fatally struck by a pickup truck. The roadway was a paved rural highway with a speed limit of 55 miles per hour. Source: NIOSH Fatalities in Oil and Gas Extraction (FOG) Database. FOG ID: 2014-048

- Worker #1 was operating a trencher to dig a ditch at an oil well drilling site for spill control. Worker #2 was walking close behind the trencher blade, kicking dirt back into the trench, when his leg got caught in the trencher, causing fatal injuries. Source: NIOSH Fatalities in Oil and Gas Extraction (FOG) Database. FOG ID: 2014-080

- Employee #1 and Employee #2 were transporting a ditching machine to a new oil rig location. The truck and trailer were unable to negotiate a new lease road with a 13 percent grade, so the two employees decided to offload the ditching machine onto the road, and drive it the remaining 200 yards to the oil rig location. After the ditching machine was offloaded from the trailer, Employee #2, an inexperienced and unqualified operator, got in the driver's seat of the ditching machine. Employee #1, who was the regular operator and very experienced, was standing on the ground between the front and back wheels. While attempting to shift the ditching machine into drive mode, Employee #2 inadvertently shifted the machine into neutral, causing the machine to immediately begin rolling down the 13 percent grade. Employee #1 ran along the side of the machine trying to stop it as it rolled down the hill. Employee #1 either tripped and fell, or was knocked down by the front tire and suffered fatal injuries to the chest and skull. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 107875585

- Employee #1 was operating a chainsaw in the vicinity of a mechanical felling operation. The company owner was using a bulldozer to push over two hemlock trees to clear the site for construction of a well pad. Employee #1 was standing directly beside the bulldozer. A dead limb fell from an adjacent tree, striking Employee #1 and fatally injuring him. Employee #1 was not wearing PPE, including a hard hat, chaps, or face protection. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 309339638

- A front-end loader operator, who was constructing a well pad, got down from the front-end loader that he was operating and did not set the parking brake. The front-end loader then rolled over and killed him. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 313636250

- An inexperienced truck driver was hauling gravel with a tractor/trailer over an existing, narrow, one-lane dirt and gravel access lease road. The final approach to the site involved driving from a terrace down a steep hill, and coming up another steep hill to the existing well site, which was the starting point for the new well pad construction. Rain showers had begun earlier in the day, causing the road to become wet, muddy, and slippery. The truck driver successfully negotiated the downgrade but then ran off the south side of the earthen dam. His truck flipped over in the water pond and he sustained injuries that prevented him from escaping the vehicle, causing him to drown. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 300474657

- A heavy equipment operator was using a bulldozer to dig a 20 feet deep by 10 feet wide pit, located 5 feet from the edge of an oilfield reserve pit filled with fluids. The wall of the reserve pit caved in and buried the operator in the mud and fluids, causing him to die from drowning. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 300575693

- An outside contractor employee was using a bulldozer to remove soil to allow the well-site to be drained of a large accumulation of rain water. During this operation, the bulldozer apparently hit a buried 8 inch PVC gas line, causing a leak and subsequent fire. The ruptured gas line was within approximately 20 feet of a Doghouse, which was occupied by three employees. The escaping gas ignited and resulted in the hospitalization of all three workers, who sustained burns to their faces and hands. Source: OSHA Fatality and Catastrophe Investigation Search Database, Inspection Number – 307006619