Oil and Gas Well Drilling and Servicing eTool

Transportation » Transporting Equipment

Work being conducted in the oil and gas industry requires a wide range of equipment to be transported. Equipment can include the entire rig, can be large and heavy, and is often transported over relatively small, sometimes inadequately maintained roads not necessarily designed for heavy truck traffic.

Tasks and key safety and health practices for transporting equipment include:

Potential Hazard

- Uneven loading surface.

Possible Solutions

- Ensure trailer is parked on a level surface.

- Secure the trailer to the pulling unit.

Potential Hazard

- Equipment slips off trailer or ramp.

Possible Solution

- Use a spotter located a safe distance away to help properly align the equipment.

Potential Hazard

- Unsecure loads.

Possible Solutions

- Loads should be tied down with proper devices for the load. (49 CFR Part 393 Subpart I, U.S. Department of Transportation)

- Loads should be inspected before and during transport.

Potential Hazard

- Load weight shifting.

Possible Solutions

- Drive slowly; loads can shift due to sudden acceleration, braking and turning.

- Inspect loads during transport.

Potential Hazard

- Attachments may release stored energy.

Possible Solution

- Lower attachments once the equipment is loaded, and set the park brake.

Potential Hazard

- Load straps suddenly release under tension.

Possible Solution

- Securing devices should be tightened to a proper tension, overtightening should be avoided.

Potential Hazard

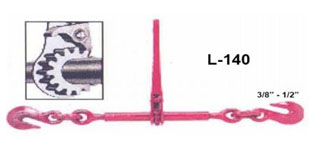

- Struck-by when using break-over style load binders.

Possible Solution

- Ensure that ratchet style load binders are used.

Potential Hazard

- Accidents resulting from wide and/or heavy loads being transported over narrow roadways and bridges.

Possible Solutions

- Conduct trip planning as a part of the journey management procedures.

- Obtain required permits (including state permits) for roadways and bridges.

- Use a flagger to communicate to drivers the current road conditions and opportunities for passage.

Potential Hazard

- Loads may strike overhead power lines.

Possible Solutions

- Keep equipment at least 10 feet away from overhead power lines. Per the National Fire Protection Association (NFPA) 70E add four inches (4") for every 10 kV greater than 50 kV. As an example, for a live 345 kV power line: The distance from the 345 kV line must be 10 feet plus four inches for every 10 kV above 50 kV. The 345 kV line is 295 kV above 50 kV. Therefore the total distance away is 10' + [295 kV x 4"/10 kV]. This calculates to approximately 20 feet away from a live 345 kV line.

- Conduct trip planning as part of journey management procedures to determine height and width restrictions along route.

- Utilize posted signs or markers to highlight overhead power lines to drivers.

- Do not allow loads to exceed 13'6" (in most states) or the load is considered oversized.

- For oversized loads, use an escort vehicle.

Potential Hazard

- When transporting equipment to a newly constructed site, the soils may not be compacted sufficiently to support the incoming load. This may cause the load to become unstable.

Possible Solution

- Ensure that the access road and pad at the well site have been properly prepared before attempting to drive on them.

Potential Hazard

- Improperly secured loads could cause equipment to slide or collapse during unloading.

Possible Solutions

- Use adequate tie-downs and techniques for securing the load.

- Train workers in hazardous conditions associated with unloading operations, including how loads may collapse when first unsecured.

- Use a spotter to monitor personnel activity during unloading operations.

Potential Hazard

- Winch cables breaking, causing cables or load to fall on workers.

Possible Solutions

- Ensure that all cables have been properly inspected prior to use.

- Ensure workers, specifically swampers, stay out of the zone where the cable may fail or break.

Potential Hazard

- Pedestrian traffic in and around the offload area may result in struck-by or caught in between hazards.

Possible Solution

- Ensure the use of designated escort and signal personnel near areas where workers not associated with the operation may be injured during equipment off-loading operations.

Incident Examples

When reviewing these incidents consider which of the Possible Solutions listed above could have prevented the incident.

- A truck driver was unloading pipe bundles that contained 13 pipes of 50 foot-long 6 inch PVC pipe from his tractor trailer with the help of a forklift operator. The forklift operator was moving one of the bundles to the laydown point when the truck driver decided to remove the tie-downs to the next layer of pipe bundles on the opposite side of the trailer. As the tie-downs were loosened, the bundle dislodged and fell on top of the truck driver causing fatal injuries.

- A worker was spotting a winch truck that was transporting a blowout preventer (BOP). A chain used to support the BOP broke causing the BOP to fall over. The BOP annular fatally struck the worker in the head and back.